Lamination process of multilayer PCB

This equipment is used to press PCB inner cores, prepregs and copper foils together to be multilayer PCB panels. It features hot oil heated beds with vacuum for outgassing. Load systems move the panels from the hot presses to the cold press/cool down stages of the process. The entire lamination process is computer controlled.

Inner layer core, copper foil and prepreg are bonded together under heat and pressure, sometimes in a vacuum, during the lamination process. The result is a panel with several layers of copper inside as well as the foil on the outside.

A-TECH use advanced vacuum lamination equipment which is able to guarantee the uniform dielectric thickness after lamination, this is extremely ideal for multilayer PCBs with impedance control requirements.

-

Lamination process of multilayer PCB

Lamination process of multilayer PCB -

Automatic copper plated(PTH) - PCB fabrication process

Automatic copper plated(PTH) - PCB fabrication process -

Drill process - China PCB manufacturing

Drill process - China PCB manufacturing -

Inner layer lay up before lamination - multilayer PCB fabrication

Inner layer lay up before lamination - multilayer PCB fabrication -

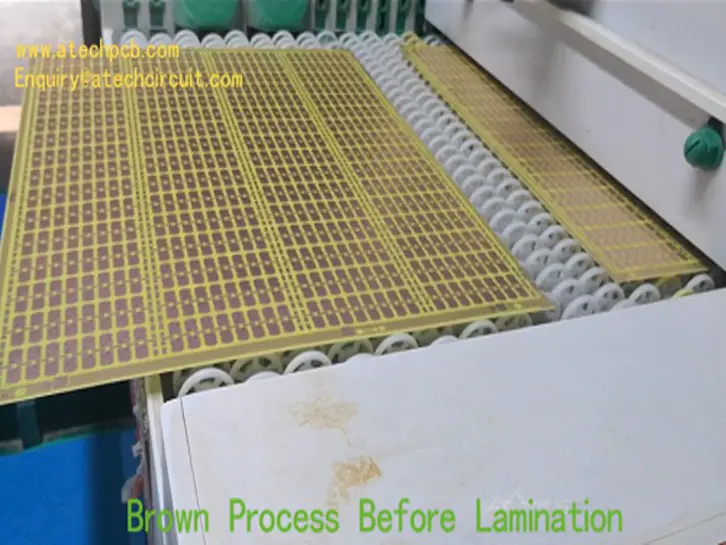

Brown process for multilayer PCB manufacturing

Brown process for multilayer PCB manufacturing -

Printed Circuit Board Manufacturing丨Inner Layer Image Process

Printed Circuit Board Manufacturing丨Inner Layer Image Process -

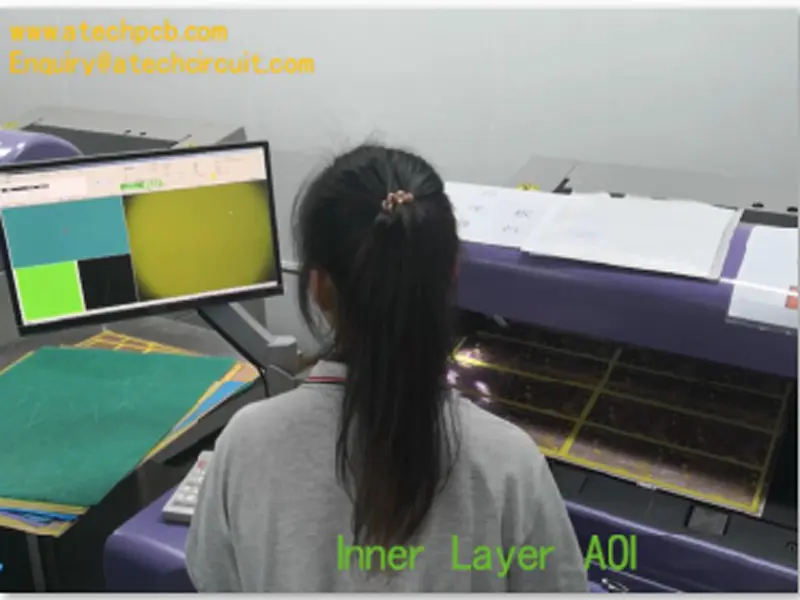

AOI for inner layer image - multilayer PCB manufacturing

AOI for inner layer image - multilayer PCB manufacturing -

Online AOI For Multi-layer PCB Inner Layer After Etching

Online AOI For Multi-layer PCB Inner Layer After Etching