Automatic copper plated(PTH) - PCB fabrication process

In order for the through holes to electrically connect to different layers of the PCB, a thin layer of copper is chemically deposited into the through holes and on the surface of copper, this copper will later be thickened through pattern plating process.

A-TECH add a desmear section in PTH line to reduce the roughness of through hole and guarantee high quality of plated copper in the holes.

Once the smear is removed, a thin coating of copper is chemically deposited on all of the exposed surfaces of the panel, including the hole walls. This creates a metallic base for electroplating copper into the holes and onto the surface. The thickness of the electroless deposit is between 45 & 60 millionths of an inch.

Share:

-

Automatic copper plated(PTH) - PCB fabrication process

Automatic copper plated(PTH) - PCB fabrication process -

Lamination process of multilayer PCB

Lamination process of multilayer PCB -

Drill process - China PCB manufacturing

Drill process - China PCB manufacturing -

Inner layer lay up before lamination - multilayer PCB fabrication

Inner layer lay up before lamination - multilayer PCB fabrication -

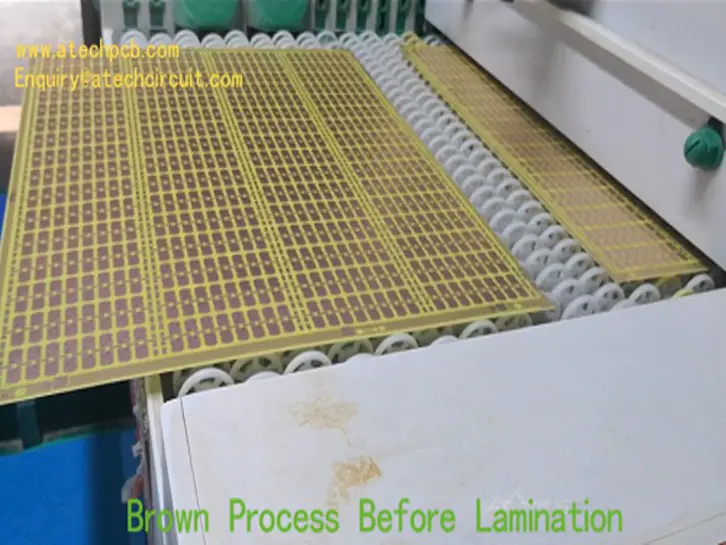

Brown process for multilayer PCB manufacturing

Brown process for multilayer PCB manufacturing -

Printed Circuit Board Manufacturing丨Inner Layer Image Process

Printed Circuit Board Manufacturing丨Inner Layer Image Process -

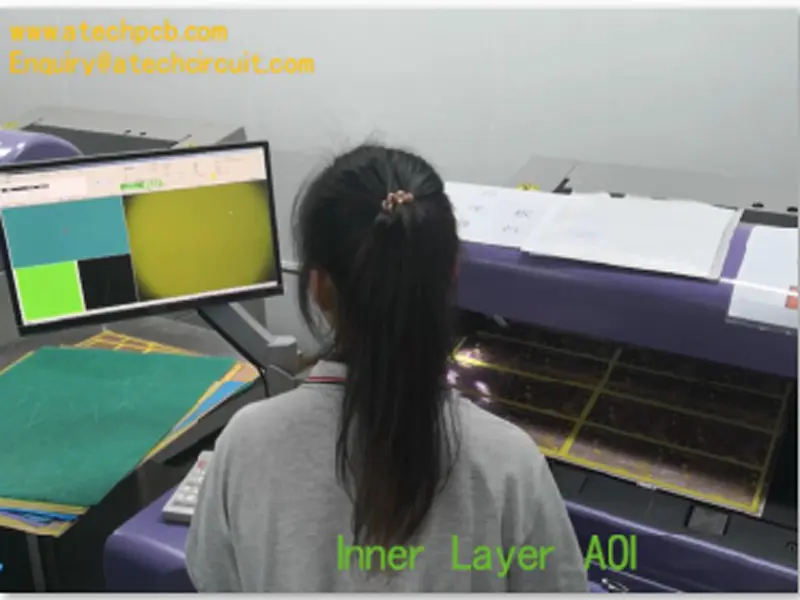

AOI for inner layer image - multilayer PCB manufacturing

AOI for inner layer image - multilayer PCB manufacturing -

Online AOI For Multi-layer PCB Inner Layer After Etching

Online AOI For Multi-layer PCB Inner Layer After Etching