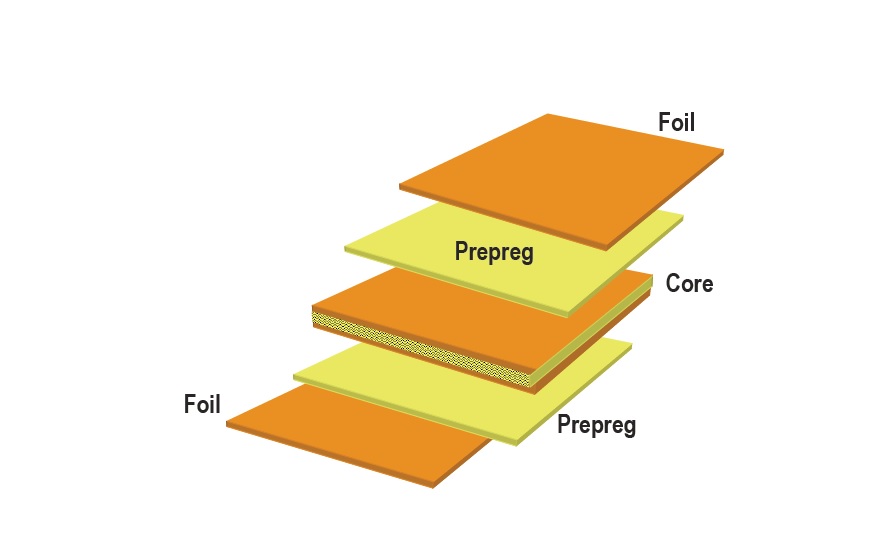

Generally speaking, the multilayer PCB board is formed by laminating and pressing a core board and a prepreg. The core board is a hard, specific thickness, two-coated copper plate, which is the basic material for the printed board . The prepreg constitutes the so-called wetting layer, which plays a role of bonding the core board. Although it also has a certain initial thickness, its thickness will change during the pressing process.

Usually the two outermost dielectric layers of the multilayer board are wetting layers, and a separate copper foil layer is used as the outer copper foil on the outside of these two layers. The original thickness specifications of the outer copper foil and the inner copper foil are generally 0.5OZ, 1OZ, 2OZ (1OZ is about 35um or 1.4mil), but after a series of surface treatments, the final thickness of the outer copper foil is generally Will increase by about 1OZ. The inner copper foil is the copper clad on both sides of the core board, and its final thickness is very small from the original thickness, but due to etching, it is generally reduced by a few um.

The outermost layer of the multilayer PCB board is the solder mask, which is what we often call "green oil". Of course, it can also be yellow or other colors. The thickness of the solder mask is generally not easy to determine accurately. The area without copper foil on the surface is slightly thicker than the area with copper foil, but because of the lack of copper foil thickness, the copper foil still appears more prominent. When we use You can feel it when you touch the surface of the printed board.

When making a printed board with a certain thickness, on the one hand, it is required to reasonably select the parameters of various materials; on the other hand, the final forming thickness of the prepreg will also be smaller than the initial thickness.

Copyright © 2025 A-TECH CIRCUITS Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.