Many customers often have such questions, should their PCBs be HAL(Lead free) finish or immersed gold finish?

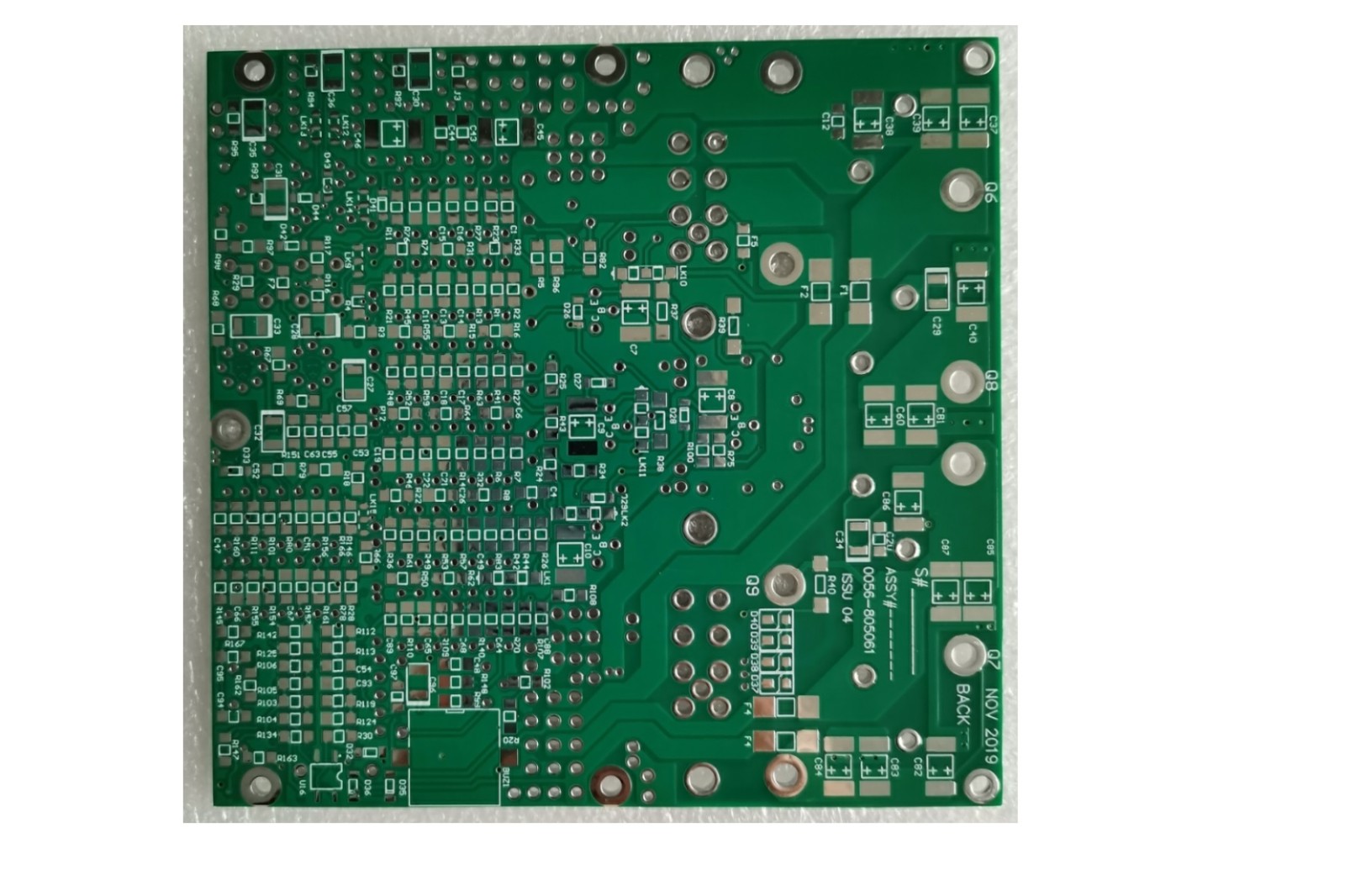

Today I'm going to popularize whether PCB board manufacturing should choose immersion gold or HAL(Lead free). If it is relatively simple and the component package is relatively large, we usually recommend customers to make HAL(Lead free) PCB. The advantages of HAL(Lead free) are good solderability, cheaper price, and less susceptible to oxidation than OSP.

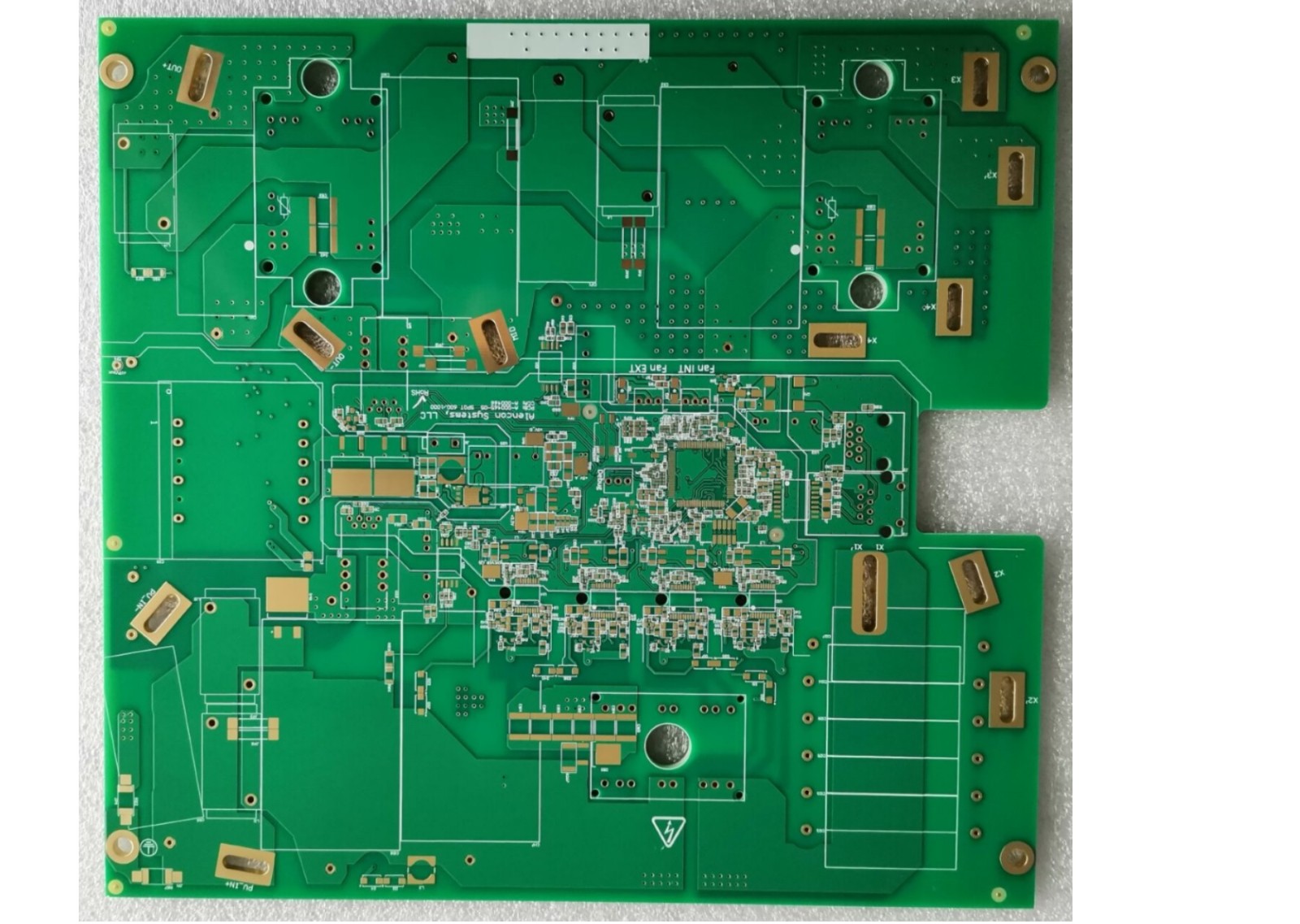

However, as the integration of ICs becomes higher and higher, the IC pins are more and more dense. Especially for very small BGAs with large PIN numbers and 0402 ultra-small surface mount components, the flatness of the pad is directly related to the quality of the solder paste printing process. influences. The vertical HASL process makes it difficult to blow the flat pads flat, which brings difficulty to SMT placement, and the Immersion Gold PCB Board solves these problems. The surface of the immersion gold is very smooth, with good solderability and not easy to oxidize. The current immersion gold PCB is not much more expensive than the HAL(Lead free) PCB.

Therefore, when encountering complex, small and dense PCB board sampling, we will recommend customers to use the immersion gold process, which will bring more benefits to the subsequent production and quality. Customers who are unsure, please consult us a lot, and A-TECH's engineers will give you some suggestions.

Copyright © 2025 A-TECH CIRCUITS Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.