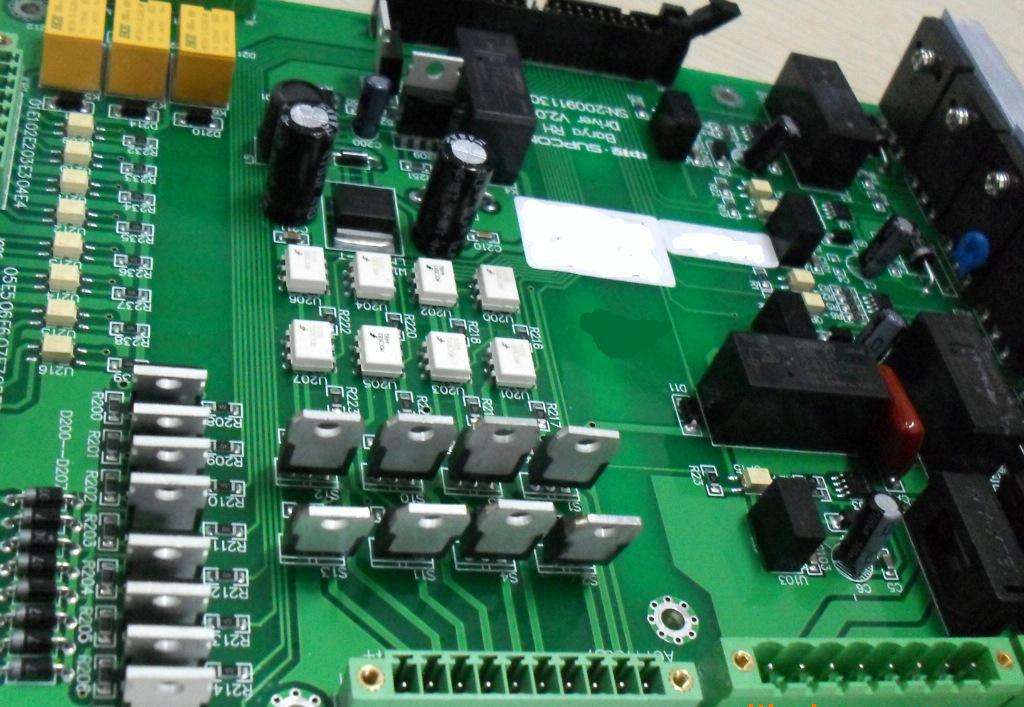

The technological process of pcb assembly processing is complicated and cumbersome, and problems may occur in each link. To ensure that the product quality is qualified, various types of testing equipment need to be used to detect faults and defects and solve the problems in time. So what are the common detection equipment in processing? What are the functions? The following will organize and introduce them for everyone.

1. MVI (manual visual inspection)

2. AOI testing equipment

(1) When AOI inspection equipment is used: AOI can be used in multiple locations on the production line, each location can detect special defects, but AOI inspection equipment should be placed in a location that can identify and correct the most defects as soon as possible.

(2) Defects that AOI can detect: AOI is generally inspected after the PCB etching process, and is mainly used to find the missing parts and redundant parts on it.

3. X-RAY detector

(1) When the X-RAY detector is used: it can detect all solder joints on the circuit board, including solder joints that are not visible to the naked eye, such as BGA.

(2) Defects that the X-RAY detector can detect: The defects that the X-RAY detector can detect mainly include defects such as bridging, voids, too large solder joints, and too small solder joints after welding.

4. ICT testing equipment

(1) When ICT is used: ICT is oriented to production process control and can measure resistance, capacitance, inductance, and integrated circuits. It is particularly effective for detecting open circuits, short circuits, component damage, etc., fault location is accurate, and maintenance is convenient.

(2) Defects that can be detected by ICT: It can test problems such as virtual soldering, open circuit, short circuit, component failure, and use of wrong materials after welding.

SMT chip processing quality assurance, in addition to the need to use these testing equipment, can not do without the strict quality management monitoring of chip processing manufacturers. A-TECH CIRCUITS as a professional PCBA manufacturers strictly control each link of production, set up nine inspection procedures, from IQC incoming inspection → SPI solder paste inspection → online AOI inspection → SMT first inspection → IPQC product inspection → offline AOI Inspection → X-RAY-welding inspection → QC manual inspection → QA shipping inspection to ensure zero-defect products and provide customers with excellent quality services.

Copyright © 2025 A-TECH CIRCUITS Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.