Basically there are 4 major types of flexible circuit boards, we'll briefly introduce as below,

1. Single-sided flexible circuit board

The lowest cost. When the electrical performance requirements are not high and single-sided wiring can be used, single-sided flexible circuit boards should be used. This most common form has been used in commercial applications, such as printer inkjet cartridges and computer memory. The single-sided flexible board has a layer of chemically etched conductive patterns, and the conductive pattern layer on the surface of the flexible insulating substrate is rolled copper foil. The insulating substrate used for flexible assembly may be polyimide (Kapton), polyethylene terephthalate (PET), aramid fiber paper (Nomex) and polyvinyl chloride (PVC).

2. Double-sided flexible circuit board

The double-sided flexible circuit board is a conductive pattern made by etching a layer on both sides of the base film. The metallized holes connect the patterns on both sides of the insulating material to form a conductive path to meet the flexible design and use functions. The cover film can protect single and double-sided wires and indicate the location of components.

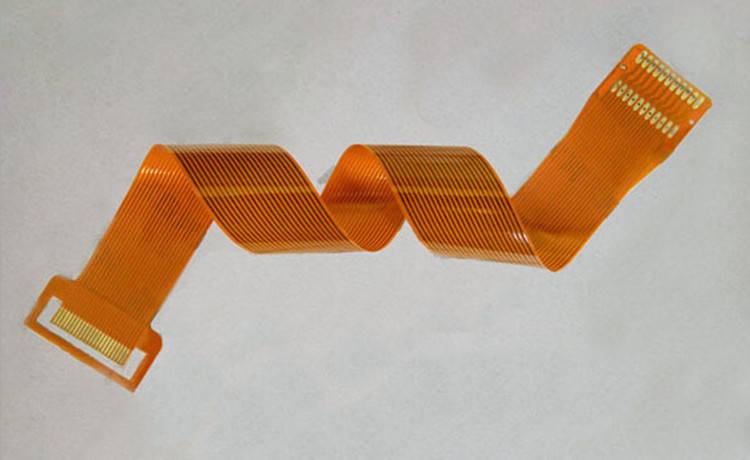

3. Multi-layer flexible circuit board

Multi-layer flexible board is to laminate three or more layers of single-sided flexible circuit board or double-sided flexible circuit board together, through drilling, electroplating to form metallized holes, forming conductive between different layers path. In this way, no complicated welding process is required. Although the number of conductive layers designed for this type of flexibility may be unlimited, in order to ensure the convenience of assembly when designing the layout, the interaction between assembly size, number of layers and flexibility should be considered.

4. Rigid-flex circuit board

The traditional rigid-flex PCB board is composed of rigid and flexible substrates that are selectively laminated together. The structure is compact, and the metallized holes form a conductive connection. Taking into account the reliability and price factors, the manufacturer should try to keep as few layers as possible.

HDI rigid-flex joint board: High-density interconnection (High Density Interconnection, HDI) rigid-flex joint printed circuit board belongs to high-end printed circuit board products, its goal is to meet the miniaturization, high frequency and high speed of electronic products The demand for growth-oriented. The HDI rigid-flex PCB board combines the strengths of the popular HDI board and the rigid-flex joint board, which promotes the high integration and high intelligent growth of electronic system design and production.

Copyright © 2025 A-TECH CIRCUITS Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.