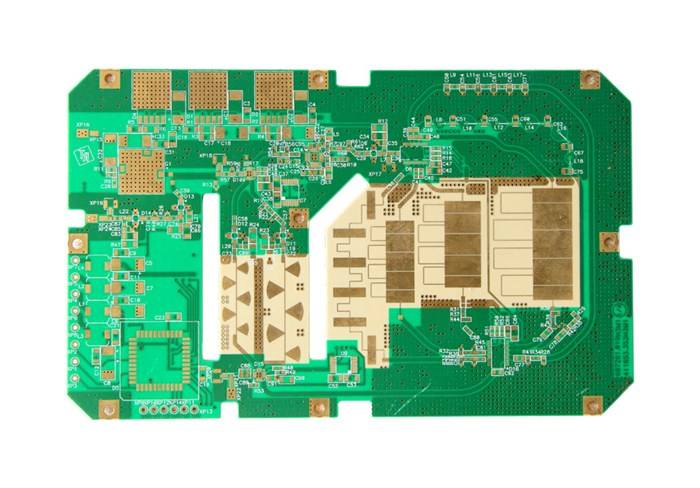

With the increase in the operating speed of microprocessors and signal conversion transmission devices, the operating speed of digital circuits has also reached a higher level: 100Gbps. The use of general-purpose PCB board will not meet the high-speed signal requirements, and the selection of circuit boards will determine the performance of the product.

The choice of PCB laminate must strike a balance between meeting design requirements, mass production, and cost. In simple terms, the design requirements include electrical and structural reliability. This board problem is usually more important when designing very high-speed PCB boards (frequency greater than GHz). For example, the material of FR4 is now commonly used, and the dielectric loss Df (Dielectricloss) at a frequency of several GHz will be large, which may not be applicable.

How to choose Rogers high-frequency high-speed laminate?

In the actual engineering operation, the selection of Rogers PCB laminate seems simple but there are still many factors to be considered. Through the introduction of this article, as a PCB design engineer or high-speed project leader, there are certain characteristics and choices of plate To understanding. Understand the electrical properties, thermal properties, and reliability of the board. And use the stack reasonably to design a product with high reliability and good processability, and the consideration of various factors is optimized.

The following will introduce respectively, the main considerations for choosing the appropriate laminate:

1. Manufacturability:

For example, how many times the pressing performance, temperature performance, etc., CAF / heat resistance and mechanical toughness (stickiness) (reliability), fire rating;

2. Various performances (electricity, performance stability, etc.) that match the product:

Low loss, stable Dk / Df parameters, low dispersion, small coefficient of variation with frequency and environment, small tolerances in material thickness and glue content (good impedance control), if the trace is long, consider low roughness copper foil.

3. Timely availability of materials:

Many high-frequency board procurement cycles are very long, even 2-3 months; in addition to the regular Rogers high-frequency board RO4350 in stock, many high-frequency boards need to be provided by customers. Therefore, high-frequency plates need to communicate well with the manufacturers in advance and prepare materials as soon as possible;

4. Cost factor Cost:

Depending on the price sensitivity of the product, is it a consumer product or an application in communications, medical, industrial, and military industries;

5. Applicability of laws and regulations, etc .:

It should be integrated with environmental protection regulations of different countries to meet RoHS and halogen-free requirements.

Among the above factors, the operating speed of high-speed digital circuits is the main factor considered by PCB selection. The higher the circuit rate, the smaller the selected PCB Df value should be. The low-loss circuit board will be suitable for 10Gb / S digital circuits; the lower-loss board will be suitable for 25Gb / s digital circuits; the ultra-low-loss board will be suitable for faster high-speed digital circuits at a rate of 50Gb / s higher.

Copyright © 2025 A-TECH CIRCUITS Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.