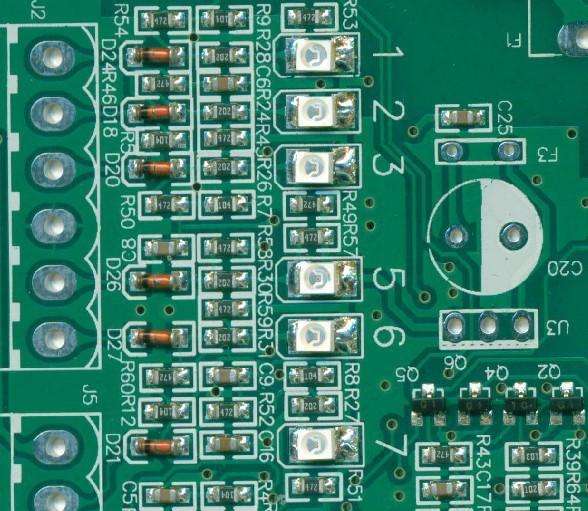

PCB (Printed Circuit Board), is an important electronic component, a support for electronic components, and a carrier for the electrical connection of electronic components. Because it is made using electronic printing, it is called a "printed" circuit board.

Development of Printed boards have evolved from single-layer PCB to double-sided, multi-layer PCB and flexible PCB, and still maintain their respective development trends. Due to the continuous development in the direction of high precision, high density and high reliability, the continuous reduction of volume, cost and performance have made printed boards still maintain a strong vitality in the future development of electronic equipment.

The domestic and foreign discussions on the future development trend of printed board manufacturing technology are basically the same, that is, high density, high precision, fine aperture, thin wire, fine pitch, high reliability, multi-layer, high-speed transmission, light weight, The development of thin type, in the production at the same time, to increase productivity, reduce costs, reduce pollution, adapt to the development of multi-variety, small batch production direction.

The technological development level of the printed circuit board is generally represented by the line width, aperture, board thickness / aperture ratio on the printed board.

The reason why PCB can be more and more widely used, because it has many unique advantages as follows,

1. High density. For decades, high-density printed circuit boards have been able to develop with the increase in integrated circuit integration and advances in mounting technology.

2. High reliability. Through a series of inspections, tests and aging tests, the PCB can be guaranteed to work reliably for a long time (usage period, generally 20 years).

3. Designability. For various PCB performance (electrical, physical, chemical, mechanical, etc.) requirements, printed board design can be achieved through design standardization and standardization, with short time and high efficiency.

4. Productivity. With modern management, standardization, scale (quantity), automation and other production can be carried out to ensure product quality consistency.

5. Testability. Established a relatively complete test method, test standards, various test equipment and instruments, etc. to test and identify the qualification and service life of PCB products.

6. Assemblability. PCB products are not only convenient for standardized assembly of various components, but also can be automated and large-scale mass production. At the same time, PCB and various component assembly parts can also be assembled to form larger parts and systems to the whole machine.

7. Maintainability. Since PCB products and various component assembly parts are standardized in design and mass production, these parts are also standardized. Therefore, once the system fails, it can be replaced quickly, conveniently and flexibly, and the system can be quickly restored to work. Of course, there are more examples. Such as miniaturization and lightening of the system, and high-speed signal transmission.

Copyright © 2025 A-TECH CIRCUITS Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.