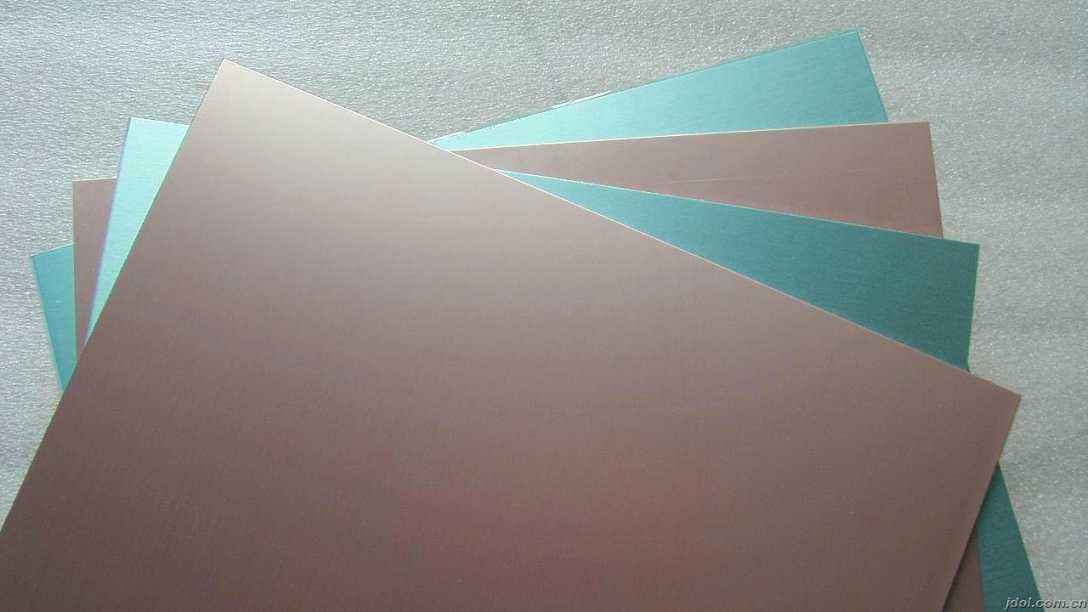

Prepreg is a thin insulating material of PCB. Prepreg is not prepreg before being laminated, also known as prepreg material, which is mainly used for the bonding material and insulating material of the inner conductive pattern of multilayer PCB. After the Prepreg is laminated, the semi-cured epoxy resin is squeezed out, starts to flow and solidifies, bonding the multilayer circuit boards together and forming a reliable insulator.

Core is the basic material for making printed circuit boards. Core is also called the core board, has a certain hardness and thickness, and double copper. Therefore, the multi-layer PCB is actually formed by pressing the Core and Prepreg.

The difference between them:

1. Prepreg is a kind of material in PCB. The former is semi-solid, similar to cardboard, and the latter is hard, similar to copper;

2. Prepreg is similar to adhesive + insulator; Core is the basic material of PCB, the two are completely different functions;

3. The Prepreg can curl but the Core cannot bend;

4. Prepreg is not conductive, and the core has copper layers on both sides, which is the conductive medium of the printed circuit board.

From the simple perspective of our PCB industry, prepreg is equivalent to the role of glue, using prepreg to connect several cores into a multilayer circuit board by lamination.

Copyright © 2025 A-TECH CIRCUITS Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.