In the production process of Flexible printed circuit boards, in order to save costs, improve production efficiency, and shorten the production cycle, they will panelization production instead of single-piece production. In flex pcb panelization, several principles need to be followed.

1. Under the premise that each process can be produced, the panelization should be "squeezed" as much as possible. The so-called "squeeze" is to reduce the distance between adjacent boards, thereby reducing the size of the entire imposition, saving production materials, and thus reducing production costs.

2. The distance between the single boards is at least greater than 2.5mm. First of all, this is to meet the needs of placing positioning holes. During mass production, molding is generally done by die punching. In order to enhance the accuracy of die punching, positioning holes need to be placed between each piece in the imposition to avoid die punching deviation. FPC is scrapped during the production process; laser cutting is generally used in the sample production process. In order to avoid micro deviations and prevent the occurrence of a partial deviation and the whole deviation, the single pieces cannot be directly connected, so that they are not mutually influences.

3. Etching characters need to be added to the panelization, and the size and quantity of the panelization will be briefly explained, so as to facilitate the verification and verification in the subsequent production.

4. Add positioning holes in the four corners of the whole imposition, and select one corner to mark different positioning holes, which is convenient for maintaining the same direction in the production of the subsequent process, so as not to cause the situation that the sealing film is stuck back and the characters are printed back.

5. The width of panelization is fixed at 250mm, and the length should be within 250mm as much as possible. The larger the imposition size, the greater the offset, the worse the production accuracy, and the higher the defective rate of the finished product.

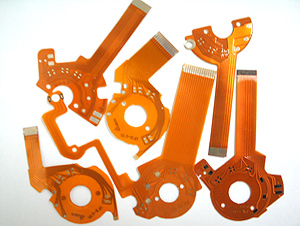

Knowing the 5 principles that panelization needs to follow, briefly introduce the three ways of panelization.

5.1. Conventional panelization. Direct array panelization in the direction of a single piece, the most suitable for regular FPC panelization, such as rectangle, square, circle, oval, etc ;

5.2. Oblique spelling. The single piece is tilted to a certain extent, and then the array is used to make the most of the panelization space, such as arcs, folds, etc ;

5.3. Fight backwards. That is, a single PCS is combined together with positive and negative.

All panelization methods follow the principle of the most material-saving under the premise of being able to produce.

Copyright © 2025 A-TECH CIRCUITS Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.