Sometimes we think that the printed circuit board manufacturing process is a very complicated matter. First of all, we must know the function and role of the printed circuit board. The first step is to supply the components and other necessary electronics to complete the first level of assembly. The base where circuit parts are joined to form a module or finished product with specific functions. Therefore, the printed circuit board process is in the entire electronic product, almost all kinds of electronic equipment, from electronic watches to computers, to communication electronic equipment, and finally to military weapon systems, as long as there are integrated circuits and other electronic components It will be used for the electrical connection between them.

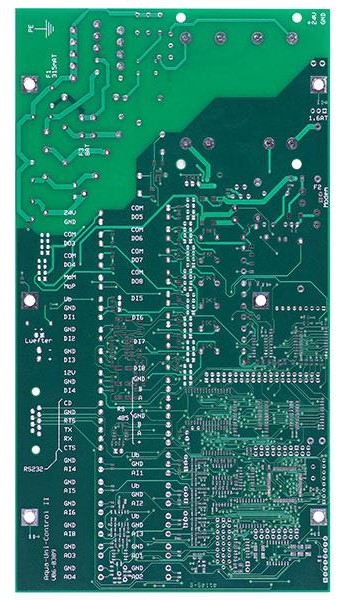

The production process of printed circuit board is generally divided into three types: single-sided, double-sided and multilayer PCB. The names of factories with different production processes are different, but the principle of the process is the same!

The single layer PCB production process is easier to understand than the double-sided process, basically it is cutting-drilling-graphics transfer-etching-solder mask and printing characters-PCB surface treatment-finished product profile-electrical test inspection-packaging Shipping.

The overall process of double layer PCB board production is: cutting-drilling-chemical copper plating and electroplating-copper-pattern transfer-pattern plating and protective tin plating-etching-intermediate inspection-solder mask- Printed characters-metal surface treatment-finished product profile-electrical testing-visual inspection-packaging and shipment.

The above is the production process of the printed circuit board. The printed circuit board has developed from a single layer to a double-sided and multi-layer board, and has maintained its own development trend. Because it has been constantly developing in the direction of high precision and high density, continuously reducing the volume, reducing the cost, and better using the printed circuit board. In the future development of electronic equipment, it still has a strong vitality.

Copyright © 2025 A-TECH CIRCUITS Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.