Osp Pcb Technology

Nontoxic PCB finish varieties are gaining popularity because of considerations behind the use of lead in manufacturing. Pb-Free HAL finishes use tin or copper paired with nickel to create a protective coating. Pb-Free HASL has the same benefits and downsides as HASL besides Pb-FREE HASL is RoHS compliant and Lead-Free. Tarnishing of the copper is one factor as this could possibly be due to oxidation of the copper floor prior to the OSP coating software.

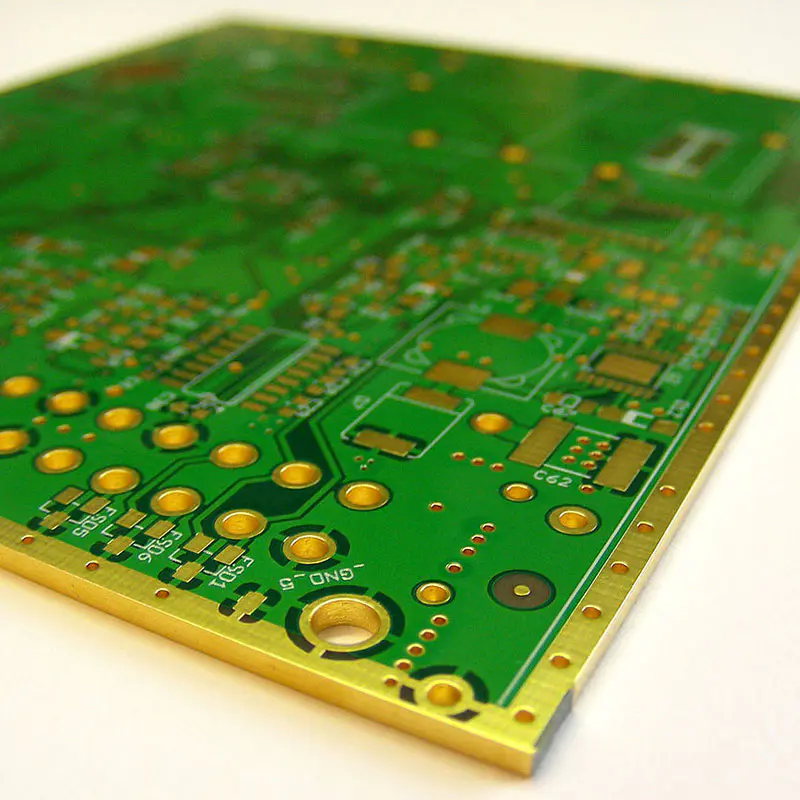

This may be relevant if some copper fingers are to be used for edge connections. As the gold is not going to tarnish, and it provides good conductivity it supplies a good connection at a low price.

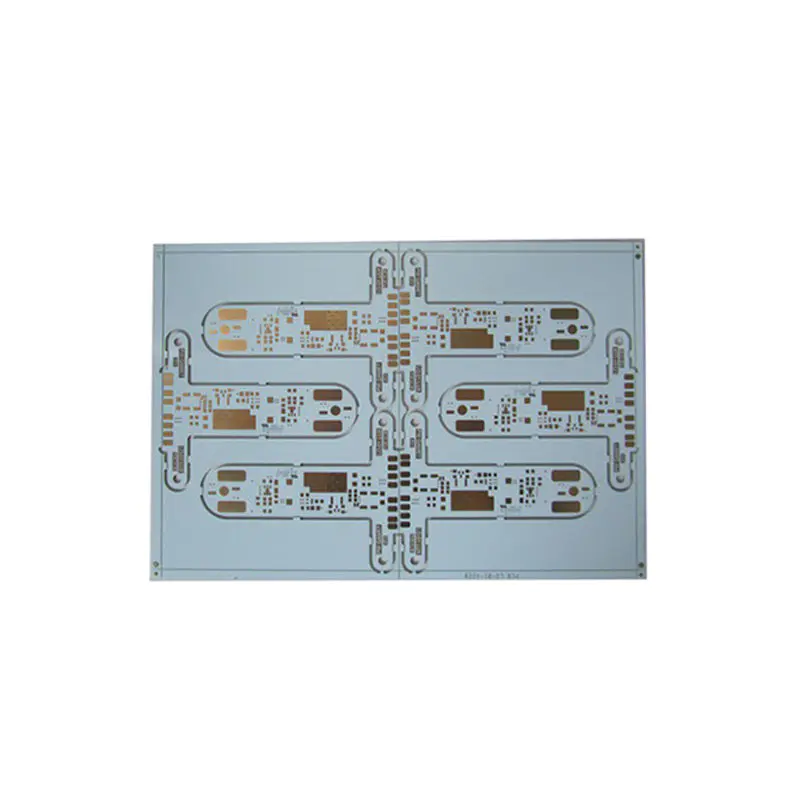

Organic Surface Preservative (OSP) is a kind of water-primarily based, organic surface finish that's sometimes utilized to copper pads on a PCB during the ultimate levels of PCB Fabrication. The finish itself is an natural chemical compound that will selectively bond to copper pads, offering an organometallic layer to guard the copper beneath. In order to enable the elements added to the board, either leaded or SMT to solder to the board easily, exposed areas of the board are normally 'tinned' or plated with solder.

This tarnish could also be difficult to remove with low activity fluxes and it will end in poor soldering. If the flux is not strong sufficient to remove those oxide the results could be non wetting of the surfaces.

The signs of this are darker shades of gold colour on the pad versus a clean coating. Typical no clear flux products will not take away the OSP to permit soldering. OSP boards tend to be cheaper than those fabricated with different surfaces corresponding to HASL, Immersion Silver or ENIG. Lead-Free Hot Air Solder Leveling (LF-HASL) is much like HASL in look and usage; however, the solder on this case accommodates a mixture of ninety nine.3% Tin and zero.6% Copper.

This alloy results in a higher melting level for lead-free solder, compared with leaded solder, requiring a slight modification for the Reflow Soldering process. LF-HASL is a replacement for leaded solder, used when a lead-free or RoHS Compliant PCB is required. Please note that a High-Temperature Laminate Material is needed for making use of this end; otherwise, the process is identical.

Having stated that id does have a finite lifetime however this is months/years not days or perhaps weeks. If your boards are wanting tarnished then this would recommend that there could be a problem with the OSP or it is not there at all, both method oxidation/tarnish of the copper may result in solderability issues. Mr. Kaminsky has 30+ years of circuit board soldering assembly expertise along with a patent for wave solder VOC flux course of. The two circumstances that will have an effect on the OSP coating are being exposed to excessive RH and Temperature.

He worked as a process engineer at a circuit board manufacturer for 5 years. Since 1999, Tony has worked for FCT Companies as a laboratory manager, facility manager, and most recently a field utility engineer. He has extensive expertise doing research and development, high quality control, and technical service with products used to fabricate and assemble printed circuit boards. OSP natural solderability preservative is designed to prevent oxidation and subsequently lack of solderability.

The manufacture of multi-layer printed circuit boards, although it makes use of the identical processes as for single layer boards, requires a significantly larger degree of accuracy and manufacturing process management. The miniaturization of digital products continues to drive printed circuit board manufacturing in direction of smaller and extra densely packed boards with increased digital capabilities. Advancements past the boards described here embrace three-dimensional molded plastic boards and the increased use of built-in circuit chips. These and other advancements will maintain the manufacture of printed circuit boards a dynamic subject for a few years.