Organic Solderability Preservative

This problem has been a priority to the electronics trade for some time and has hurt the reputation of ENIG as a last finish, limiting in some instances its wider adoption. With this in thoughts, coupled with the very excessive price gold currently achieves on the open market (in excess of 1300 per troy ounce) the business is in search of another expertise. Recently restrictions on cyanide in certain regions of the world have also put stress on these using ENIG. Ideally, an acceptable alternative would retain the constructive options of the ENIG end while, at the same time, eliminate the black line nickel concern and be far more economical with out using cyanide.

As talked about above, electronic components are now incessantly uncovered to harsh, corrosive environmental and use conditions. Long time period publicity to such environments may end up in the onset of varying degrees of corrosion phenomena, similar to creeping corrosion, peeling and coating tarnish. These phenomena could be mitigated by the adoption of best application practices and meeting processing, along side using specially formulated anti-corrosion coatings.

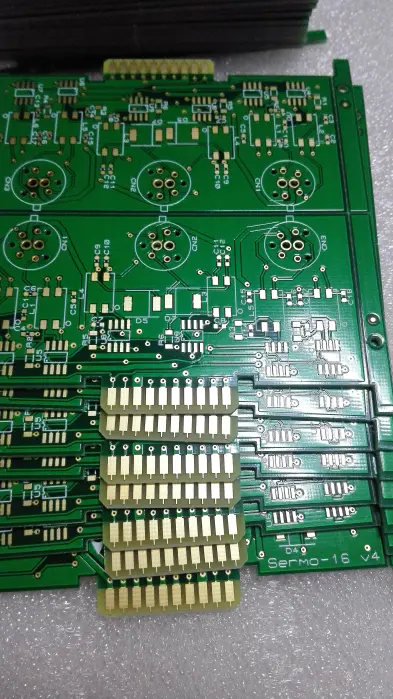

ENEPIG, also called Electroless Nickel Electroless Palladium Immersion Gold, differs from ENIG in that a layer of palladium is applied as a resistance layer to cease nickel from oxidation and diffusion to copper layer. Compared to different types of floor finishes, ENIG and ENEPIG present the best solderability for PCBs however the fee is much higher. The distinction between manufacturing processes of ENIG and ENEPIG can be present in Figure three below. Organic Solderability Preservative(OSP) is an anti-tarnish surface finishing utilized in printed circuit boards.

In this, the copper floor is preserved from oxidation by applying a skinny layer of protective materials. This compound produces an organometallic layer that protects the copper beneath. OSP is a non-toxic, environment-friendly surface ending course of, and price efficient compared to many different surface finishing strategies, please contact us at the earliest. OSP is particularly designed to provide the skinny, protecting, and uniform layer on the copper floor of PCB’s.

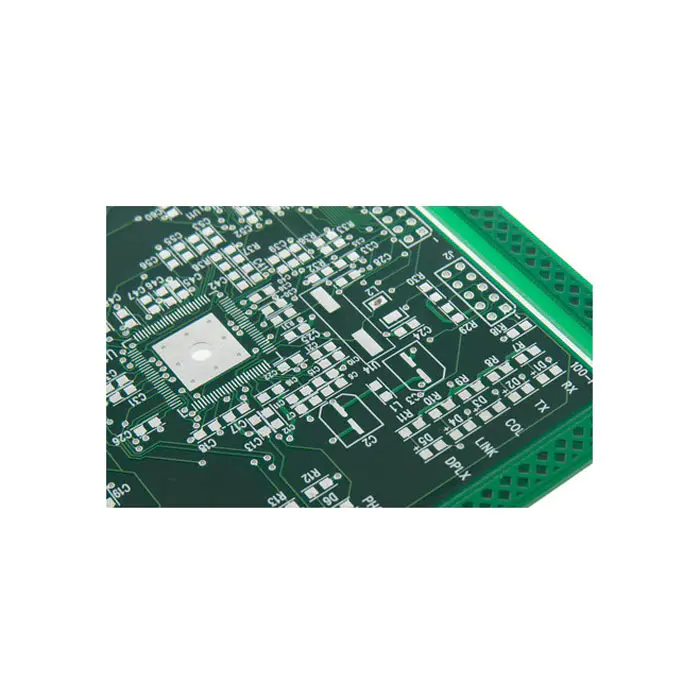

One common floor end now regularly used within the electronics trade is immersion silver. The reputation of this technology has elevated over the last decade and now accounts for about 10% of the final end market. The recognition of immersion silver is driven by factors such as, excellent solderability, very low contact resistance; straightforward of meeting and testing, and it is a comparatively low price possibility.

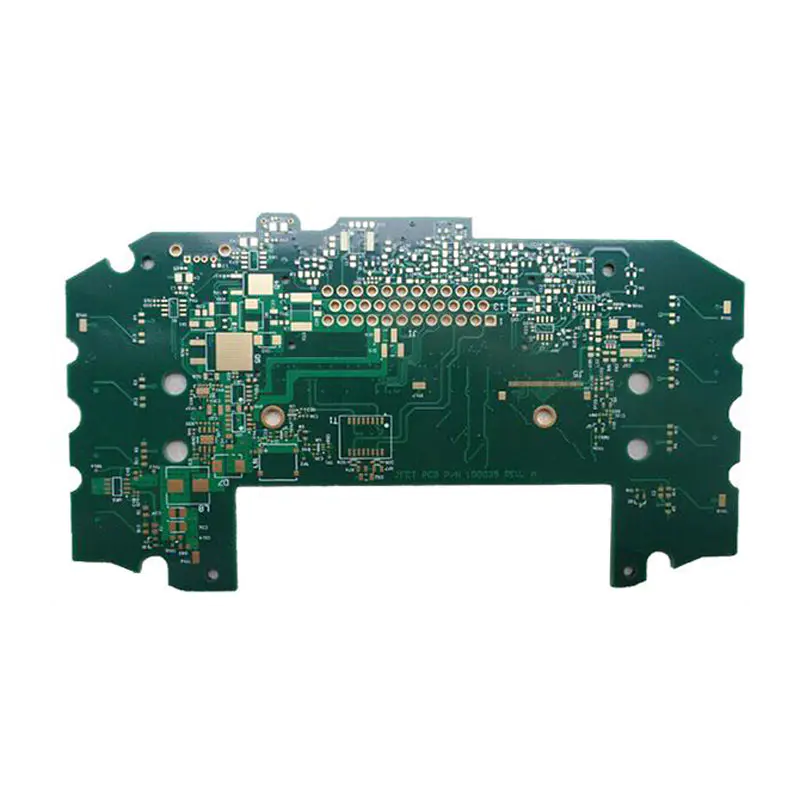

This paper particulars such a process; electroless nickel/immersion silver. Careful choice of the electroless nickel and immersion silver processes lead to a surface finish that has superior operate, efficiency and is low value. Price, availability, shelf life, reliability and the meeting process are key components when choosing a PCB surface end. While each finish has its own benefits and downsides, typically, the process, product or environment will dictate the surface end that is best suited in your utility. For instance, in case your printed circuit boards do not need to be RoHS, Sn/Pb HASL could also be your best option.

This coating really protects the circuitry from oxidation throughout storage and meeting. This finish truly preserves the copper surface from oxidation by providing an organometallic layer protecting the copper prior to the soldering process. It can also be a water-based mostly natural surface finish, which implies this floor end is environmentally pleasant.

With Pb-free solder, corresponding to SnAgCu alloys (especially SAC305), the elastic modulus is 25% higher. When stress is utilized, the solder doesn't deform as simply and the stress concentrates on the intermetallic interface. As a result, when a Pb-free PCB with ENIG or ENEPIG end undergoes board pressure because of deflection or a drop/shock event, solder joint failure occurs at decrease pressure ranges than with the other floor finishes. This layer can be so fragile that cracks can typically be discovered at this interface on Pb-free assemblies that had not even seen mechanical testing, as proven in Figure 8. ENIG, quick for Electroless Nickel Immersion Gold, consists of electroless nickel plating coated with a thin layer of immersion gold, which protects the nickel from oxidation.

Compared to other surface finishes which have high ranges of toxicity or devour giant quantities of power, this surface finish is relatively protected and “green” for the environment. The sixty three/37 tin lead solder has been the business-standard because the inception of the unique circuit board. If lead-free just isn't a priority, HASL is a very cost efficient, dependable floor end utilized within the manufacturing of decrease expertise PCBs. The HASL process can add stress to high layer circuit boards which may trigger lengthy-time period reliability issues. This added stress, together with uneven solder top on dense SMT or BGA pads, are good causes to exchange HASL.

If your boards need to be RoHS and have fine pitch components including BGA’s we suggest ENIG or immersion silver. On circuit boards with finishes corresponding to OSP, ImAg, HASL or ImSn, the tin primarily based solder bonds on to copper with formation of Sn-Cu intermetallics. In the case of ENIG and ENEPIG the tin varieties intermetallics with the nickel layer. In this case the intermetallic is mostly Ni6Sn5 which is extra dense and brittle than the copper based mostly IMCs. With the use of eutectic SnPb solder, the elastic modulus of SnPb was quite low and this allowed the solder to deform and take in stress on the joint.