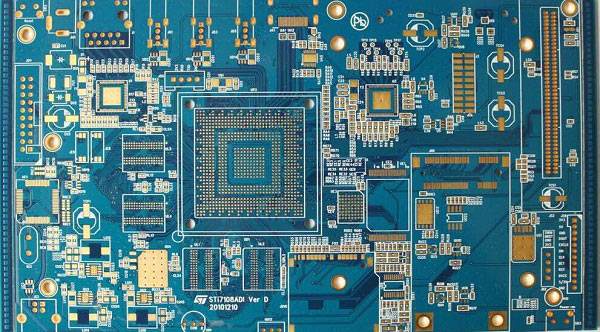

The PCB short-circuited, the main reason is that the film line is scratched or there is garbage jam on the coated screen. The coated anti-plating layer is exposed to copper and the PCB is short circuited. The improvement is as follows:

1、Films must not have trachoma, scratches, etc. When placed, the film surface should face up and must not rub against other objects.When the film is copied, the film is operated on the surface of the drug film, and after being used up, it is put into a suitable film film bag and stored in time.

2、When facing the film, face the PCB surface finish. When taking the film, use both hands to pick up the diagonal. Do not touch other objects to avoid scratching the film surface. Each film must stop the alignment when the plate reaches a certain number. Or replace it, put it in a suitable film bag after use.

3、The operator should not wear any decorations such as rings, bracelets, etc. on the hands. The nails should be trimmed and kept slippery. No objects should be placed on the surface of the table. The table should be clean and smooth.

4、Before the screen version is produced, it must be strictly checked to ensure that there is no problem in the screen version. When applying the wet film, it is often necessary to check the paper to check if there is any jam on the screen. When there is no printing at intervals, the empty net should be printed several times before printing, so that the diluent in the ink can fully dissolve the solidified ink to ensure the smooth leakage of the screen.

Copyright © 2025 A-TECH CIRCUITS Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.