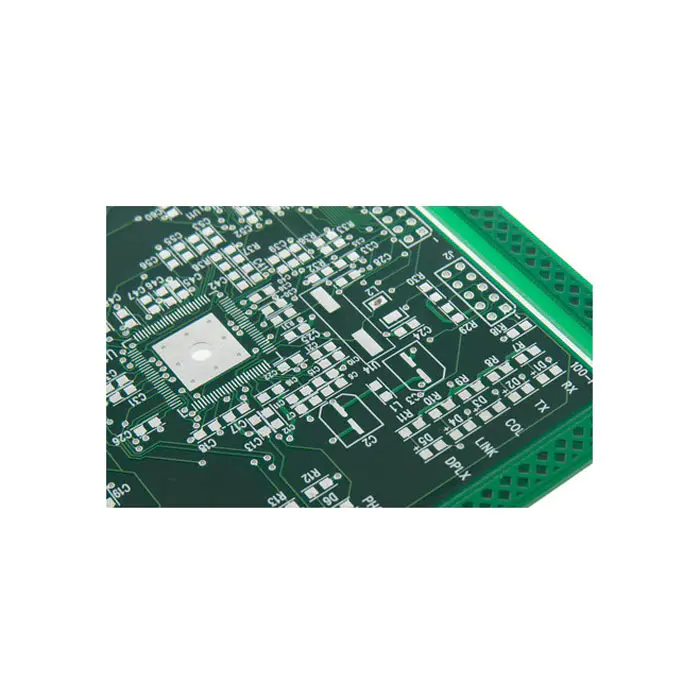

Immersion Gold Plating

In ENEPIG the palladium interlayer acts to guard the nickel layer in the course of the gold plating course of but dissolves into the solder throughout reflow, yielding an oxide-free activated web site for an optimum bond to the parts. The gold and palladium layers are inert and don't oxidize, resulting in glorious shelf life. Once the gold and palladium are dissolved in the course of the soldering course of the remaining layer of nickel prevents copper leaching into the solder. OSP (Organic Solderability Preservatives) is the go-to floor end for copper pad purposes. It is a really particular surface finish and as you can see has a number of cons associated with it.

The current invention is directed toward enhancements within the treatment and removing of OSP coatings previous to reflow soldering of a PCB. In particular, the present invention uses a plasma atmosphere to deal with and remove the OSP coating prior to the PCB entering the reflow soldering process. The method of the current invention overcomes the disadvantages associated with the prior art methods of eradicating the OSP.

As seen above, HASL can still be a good possibility for a surface end, however improvements in different surface finishes are making it obsolete. HASL does have a couple of benefits, but compared to others like ENIG, ENEPIG, and other immersion finishes, it is falling quick. For instance, ENIG is corrosion resistant, good for aluminum wire bonding, excellent for fine-pitch expertise, wonderful solder-ability, has an excellent shelf-life, and so much extra.

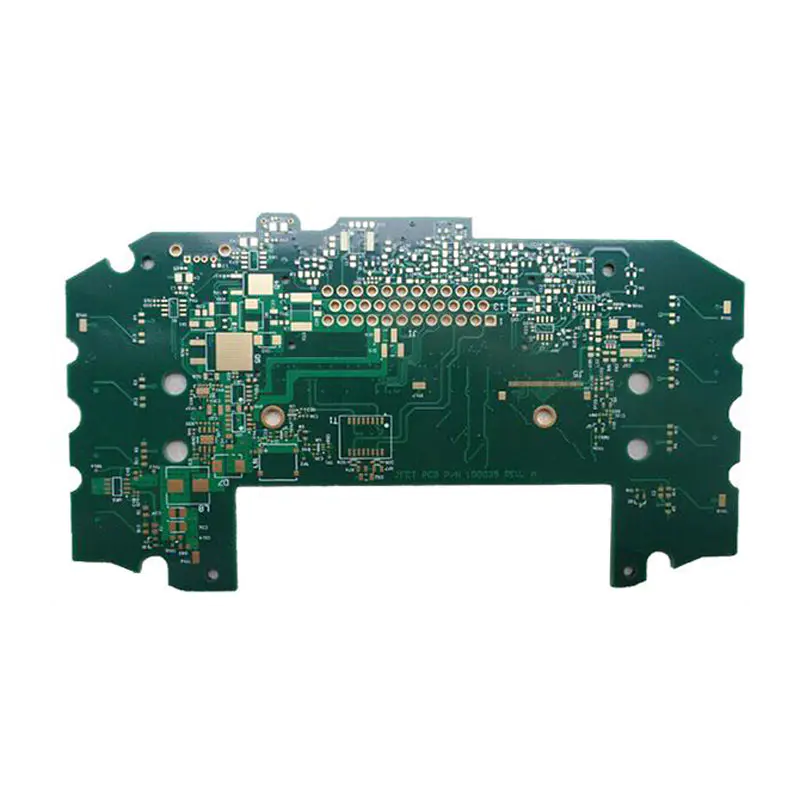

In a more expanded view, the final end coating is required to meet dozens of practical criteria, together with solderability, environmental, electrical, bodily, and sturdiness demands. The finish of a board, which is usually overlooked, is the interface between the board and the elements that make the board perform as desired.

But for essentially the most part, OSP is a great selection for an organic resolution for your floor finish. It also has a bonus over conventional HASL as regards to coplanarity, and its solderability. However, this end does require vital modifications with the type of flux and variety of warmth cycles used throughout meeting course of.

In explicit, no special solvents or special reflux materials are wanted in the present invention, thus eliminating additional materials costs and concerns. In addition, the plasma ambiance may be created within present stream lined working techniques. Moreover, the strategy of the present invention doesn't generate extra waste water and can be utilized successfully even with smaller electronic component sizes without reduction of high quality or reliability of the solder joint. The second identified technique for eradicating the OSP layer is to make use of a extra highly reactive flux within the solder paste combination, such flux serving to dissolve the OSP layer through the pre-warmth stage.

To the untrained eye, there is not a lot variation in how completely different finishes look or carry out on a circuit board, however, with time and experience, refined and not-so-delicate variations emerge. Lead-free solder or contamaination resulting from the solder process regularly leads to contacting issues, and the pseudo errors related to them in the course of the means of contacting surfaces with OSP coating. In addition OSP and flux residues are inclined to accumulate on the plunger tip.

This methodology also can add cost and waste to the method, but has a extra serious problem related to continuing device miniaturization. In particular, because the digital element measurement continues to decrease, the scale of the conductive pads and the hole between components on the PCB also decreases. This in turn results in the necessity to use much less solder paste and thus much less flux for any explicit pad. The reduced amounts of flux may not be efficient to completely dissolve the OSP layer which might trigger each quality and reliability points for the solder joint.

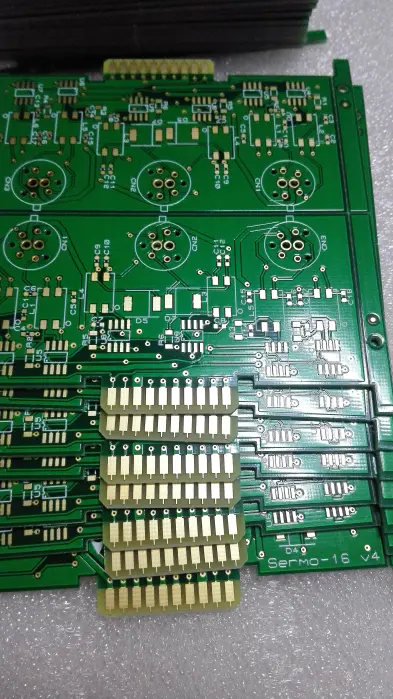

In order to keep the contamination on plunger tips to a minimum, and to reliably penetrate the highest layer on the soldered factors, aggressive tip types with a specialised palladium-nickel plating developed by INGUN is used. Printed Circuit Boards (PCBs) kind the inspiration of contemporary automotive electronic circuit. They assist the assembly of electronic ignition techniques, transmission control units, digital lamp driving, navigation methods, and lots of others in a vehicle. subjecting the printed circuit board to a plasma environment previous to the printed circuit board being processed in a reflow soldering system.

In terms of ICT, only OSP is the worst while others are just equally good. In phrases of HOLE FILL, HASL and ENIG are higher than the other types. Among the most costly PCB surface end sorts, onerous gold purposes are extremely durable and have a protracted shelf life. It is not often used for soldering factors, as a result of poor solderability. As its most important perform, the ultimate end course of is intended to offer exposed copper circuitry with a protective coating so as to preserve solderability.