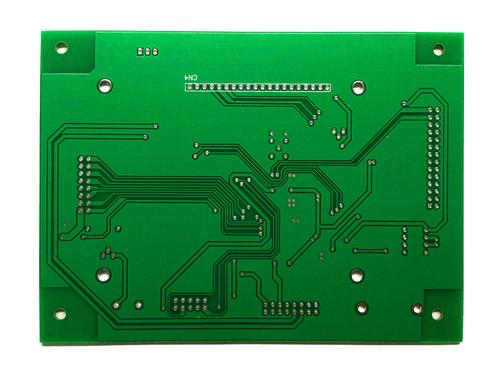

Single sided PCB or called 1 layer PCB is widely used for consumer electronic, normally it requires large volume in the worldwide market but also requires lower cost, it doesn't require high level of technology to manufacture 1 layer PCB, basically all PCB manufacturers are capable of fabricating 1 layer PCB, themain difference is the production efficiency and yield rate output, A-TECH is able to do these aspects quite good to make us in the front line of manufacturing 1 layer PCB.

The manufacturing process for single sided pcb is quite simple and there are not so many processed like double sided pcb or multilayer pcb, the complete manufacturing process include: cut sheet, drill, layer image, solder mask, silkscreen, surface finish, profile, electrical test, FQC, package. The manufacturinglead time is also short and it can be finished and shipped quickly with only a few days.

The surface finish is one of the most important factor for single sided PCB, HAL(Lead Free) finish is one of the most popular surface finish for single-sided PCB, it's economical and it's also RoHS compliance, basically the cost is the most important factor for customers to consider when they purchase single-sided PCB, so HAL(Lead Free) could be one of the most suitable choice. A-TECH own HAL(Lead Free) line in house, so it's convenient for us to do HAL(Lead Free) finish.

Except for HAL(Lead Free), there are also lots of customer select to use HSAL finish for single-sided PCB, even though HASL is not RoHS compliance, but the production cost can be even lower than HAL(Lead Free) and the solderability can be better. A-TECH own HASL line in house, so we're able to support single-sided PCB with HASL finish better.

Copyright © 2025 A-TECH CIRCUITS Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.