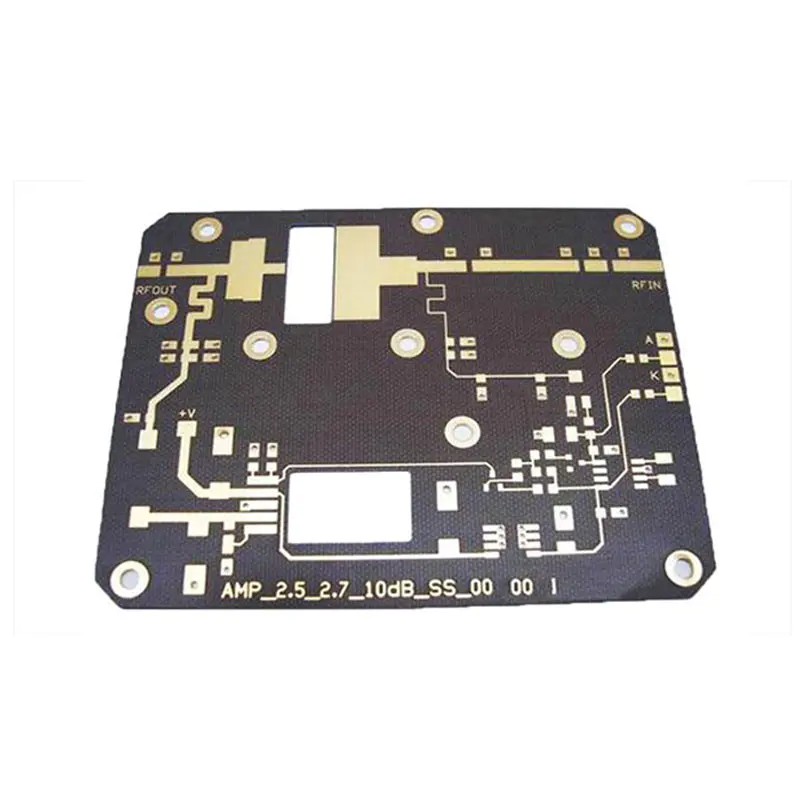

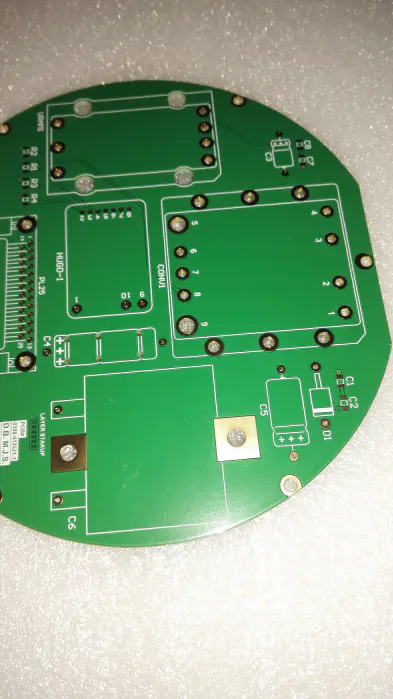

China Blue Ink Surface Finished Circuit Board Osp Pcb

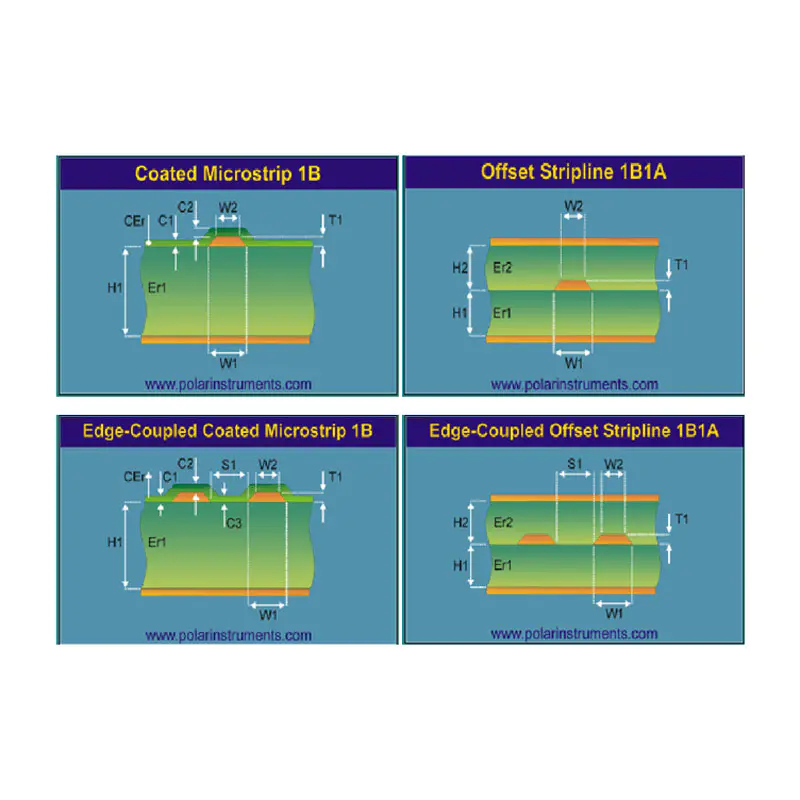

When it comes to selecting the best kind of ultimate floor finish, it is simply as important as choosing the proper material in your bare board. Selecting the correct surface finish on your software is critical for performance. For assistance with deciding on a floor end, ship our trusted engineers an e-mail or call. Additionally, the sort of floor finish used on the PCB will significantly affect the overall value of the piece.

OSP Finish is ideal for fine pitch assembly for the reason that clean surface allows the stencil to press firmly against the surface of the copper pads. Immersion Silver is likely one of the newer additions to the record of surface finish choices.

ENEPIG is probably not new to you, however it's a surface end that has turn into more and more well-liked just lately due to the price reductions in palladium. It also has increased in recognition and use because of its many features and benefits. It additionally has a definite benefit over the ENIG floor finish, which we’ll get into beneath.

During over-reflow welding, the movie can't face up to high temperature ( levels C), which ultimately impacts the welding performance. On the digital assembly line, the movie cannot be nicely dissolved by flux and affects the welding performance. It is appropriate to control the movie thickness between 0.2 and 0.5 um. However, within the subsequent excessive temperature welding, the protecting movie have to be simply removed by flux, in order that the copper floor could be combined with molten tin to type a strong solder joint in a very quick time.

For more information, obtain ourSurface Finishes Chart, that can assist you decide the best floor end in your PCB wants. Another end that's ideal for these in search of a flat floor finish is Immersion Tin. However, one vital downside with Immersion Tin is the truth that it is made up of the carcinogenic ingredient Thiourea.

It has been used primarily in Asia and is continuous to grow in popularity in each North America and Europe. These coatings have been used with nice success on many boards regardless of their larger per unit value. Filming It is better to make use of DI water for laundry earlier than film forming so as to stop fouling of film forming liquid. DI water can also be one of the best water for washing after movie formation, and the PH worth should be managed between four.zero and seven.0 so as to prevent the movie from being polluted and destroyed. The key of OSP process is to regulate the thickness of anti-oxidation film.