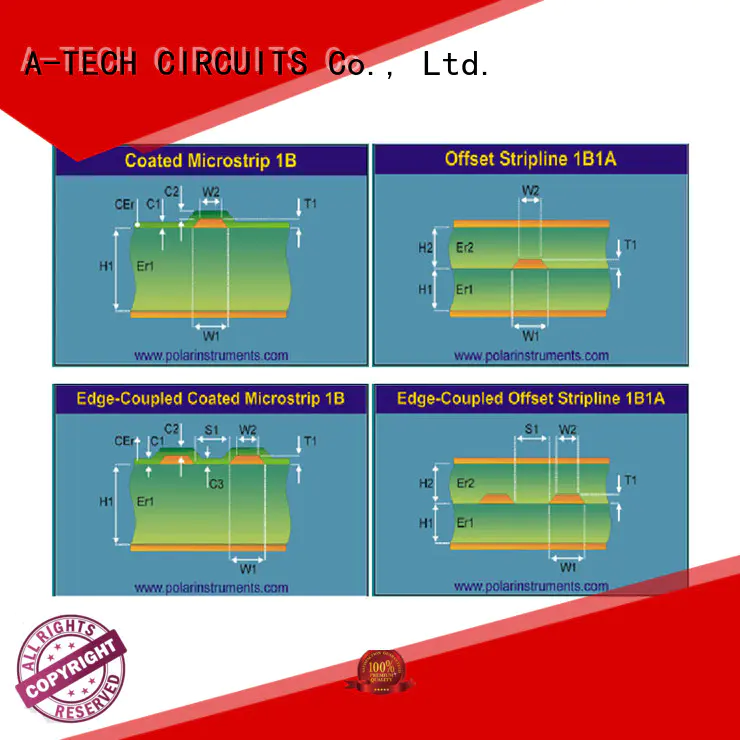

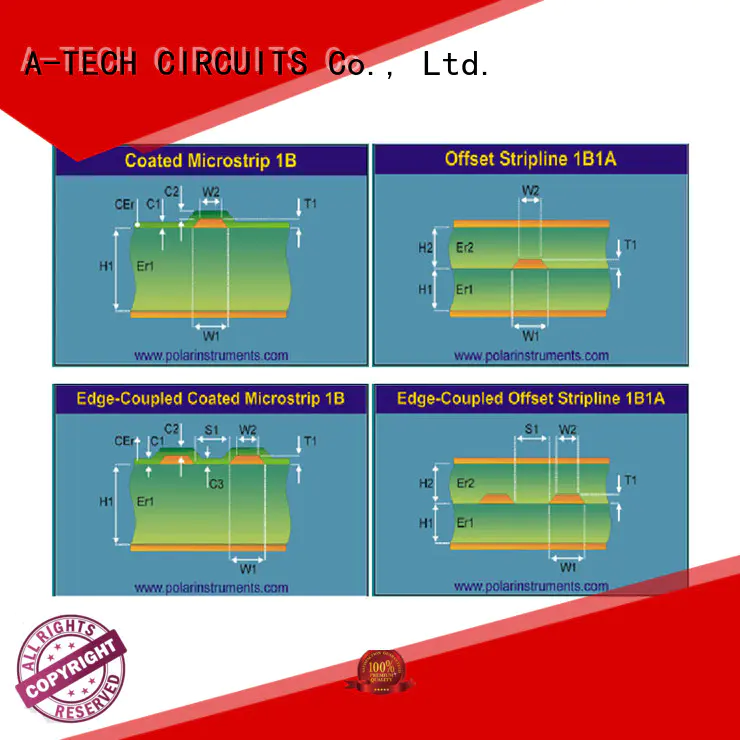

Impedance is the combination of the capacitance and inductance of a circuit when operated at high frequency. Control impedance in printed circuit boards are used across a broad range of applications to help ensure high signal integrity. Basically there are usually three types of impedance in PCB designs like single-ended impedance, differential impedance and coplanar impedance.

The factors affect impedance include: impedance trace width/spacing, copper thickness, dielectric thickness on either side of the impedance traces, dielectric constant of the core and prepreg material etc.

The applications of impedance control PCB include RF communication, Signal processing, High quality analog video, Computing 100MHz and above, Telecommunications and so on.

A large proportion of multilayer PCBs that A-TECH manufactured are with impedance control requirements, normally we will calculate impedance based on stack up and gerber designs to match with specified impedance values, our engineering dept might do necessary adjustments on stack up or impedance trace width/spacing if there is any mismatch after calculation. Moreover, the impedance coupons will be placed in each working panel which use for testing impedance values before shipment.

Copyright © 2025 A-TECH CIRCUITS Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.