Company Advantages1. The design of A-TECH

countersink pcb is unique. It is carried out by our designers using new types of fabrics, new colors, and innovative structures.

2. Properties like

hybrid circuit manufacturers of countersink pcb help customers highly minimize their costs of operation and maintenance.

3. countersink pcb is a preferred high-tech product with such features as hybrid circuit manufacturers .

4. The product has a smooth surface and a delicate texture. I love this product as it didn't have any problems such as cracks and burrs. - One of our customers said.

5. The product is environmentally friendly. People can recycle, reprocess, and reuse it for times, helping to reduce carbon footprint.

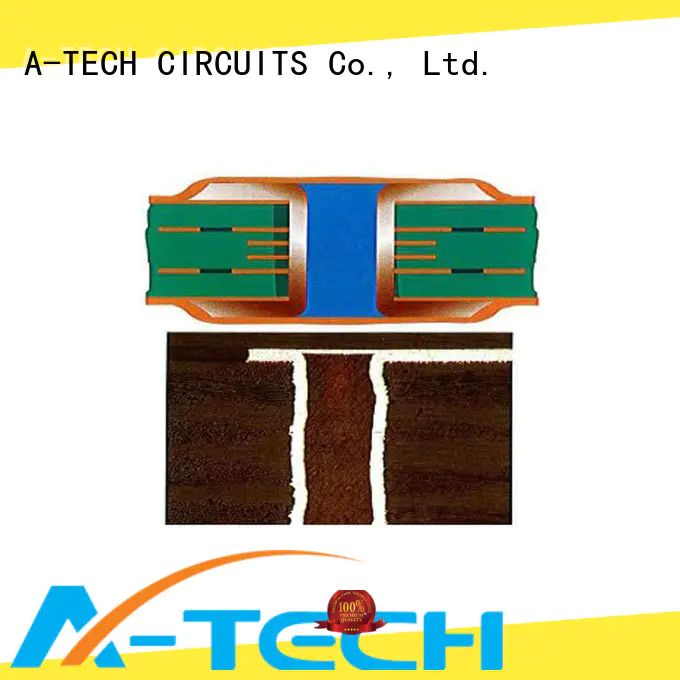

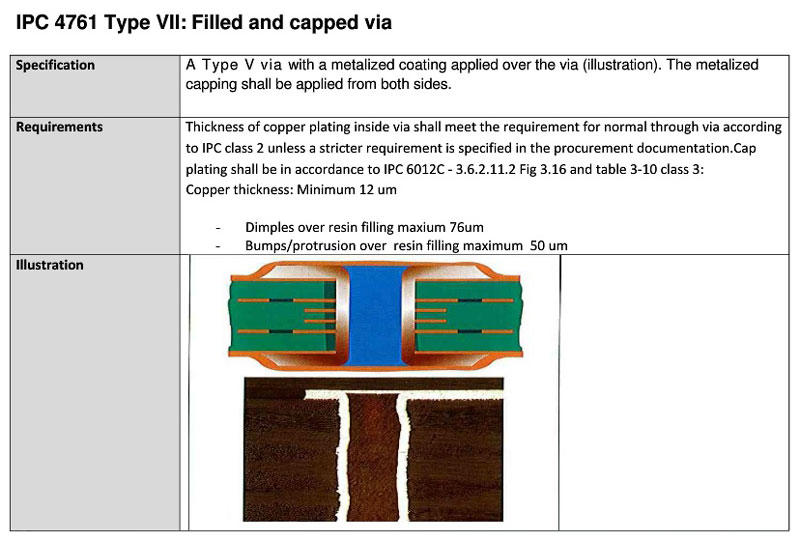

Via In Pad (VIP) technology refers to the vias in SMD pad or BGA pad due to small space for layout, in order to avoid the solder paste flow into inner layer or the other side in assembly production, basically this type of via need to be plugged with resin and plate copper over to cap the via to make it invisible.

Via in pad technology is widely used in high density PCBs, especially for the PCBs that require a limited BGA space and are focused on heat transfer and high speed design. Although blind holes and buried holes help increasing density and save space on the circuit boards, through holes are still the best choice for thermal management and high speed design elements.

The advantages of Via In Pad technology

● Suitable for fine pitch BGAs

● Improved thermal dissipation

● Provides a flat, coplanar surface for component attachment

● Leading to higher density of PCBs and promoting space saving

● Overcomes high speed design issues and constraints.

● Meets closely packed placement requirements.

The Via In Pad technology is defined in IPC standard with IPC-4761 VII

A-TECH manufactured lots of multilayer PCBs with Via In Pad designs Both in BGA Pads or in other SMD Pads, we’re able to plugged vias fully and then plated copper over to make the surface of pad as flat as other pads without dimples.

Company Features1. A-TECH CIRCUITS Co., Ltd. holds a dominant market position in the relevant markets. We are always the first choice when it comes to choosing the manufacturer of hybrid circuit manufacturers .

2. We have a hardworking workforce that is focused on helping our business grow. With their years of industry experience, they are able to help our customers to achieve their business goals.

3. We aim to pioneer new solutions for sustainable development while continuing to shape our business responsibly and increase our economic success. This ambition encompasses all of our company’s activities – along the entire value chain. Undertaking social responsibility initiatives is truly a win for our company. We believe that true success comes when everyone focuses on the bigger picture and here, the bigger picture isn't just about manufacturing products—it's about trying to change the world for the better. We strive to promote our sustainability program by working together with our customers and suppliers and fostering a company-wide culture of sustainability. In our future development, we will stick to responsible production approach which takes into consideration social and environmental needs, and demonstrate our commitment to sustainability.