An Introduction Of Organic Solderability Preservative

In fact, many producers will perform DFM evaluation prior to manufacturing to identify and repair points. Performing your personal analysis prior to the prototype might have detected those self same issues and altered them in engineering, allowing you to include the modifications into the PCB design where they belong. Doing so would have lowered the fee, maintained design intent, and ensured observe-on builds also work correctly. The most essential thing to notice is that every one the components on a printed circuit board held mounted to the board.

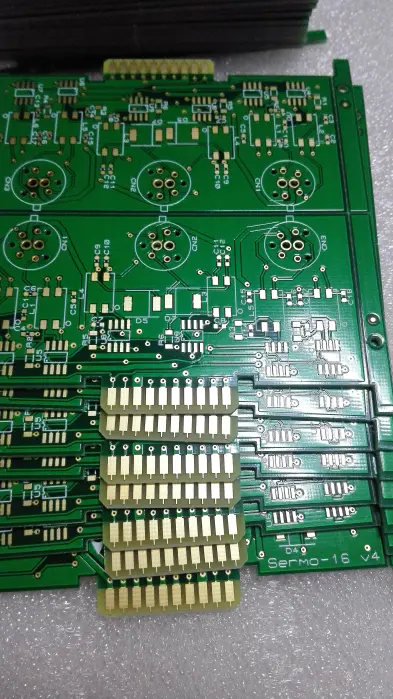

These holes are called blind vias when they join an inside copper layer to an outer layer, or buried vias when they join two or extra inner copper layers and no outer layers. Laser drilling machines can drill 1000's of holes per second and may use either UV or CO2 lasers. The (semi-)additive process is often used for multi-layer boards as it facilitates the plating-by way of of the holes to produce conductive vias within the circuit board. A field of drill bits used for making holes in printed circuit boards. While tungsten-carbide bits are very exhausting, they eventually wear out or break.

However, castellations are additionally used when combining two boards to make sure the solder inspection joint is correctly structured and to create wi-fi PCB to PCB hyperlinks. Often design groups look at DFM as a “manufacturing downside” and one thing dealt with by their contract manufacturers or downstream companions.

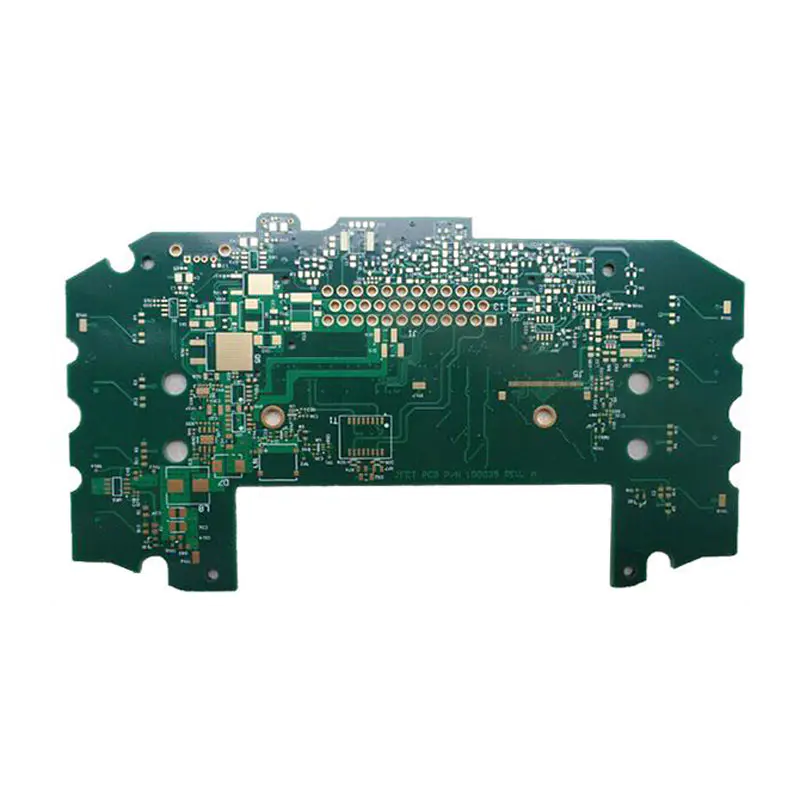

This allows circuits to be accomplished using less area, liberating up space to allow the board to complete more features, normally at higher speeds and a lighter weight than a through-gap board would allow. A single-layer or single-sided PCB is one that is made out of a single layer of base material or substrate.

We can deal with the basics of PCB design like floor mountings or via-gap connections, but in addition tougher blended assembly products. As a part of our quality management, we offer design for manufacturability (DFM) test. We can even do particular operate tests based mostly in your necessities to ensure PCBs we fabricate meet the design specs they had been created from. Due to its ease of assembly, manufacturing printed circuit boards out of aluminum can also be a great way to preserve power. Instead, many small leads are soldered on to the board, meaning that the board itself is used as a wiring floor for the totally different parts.

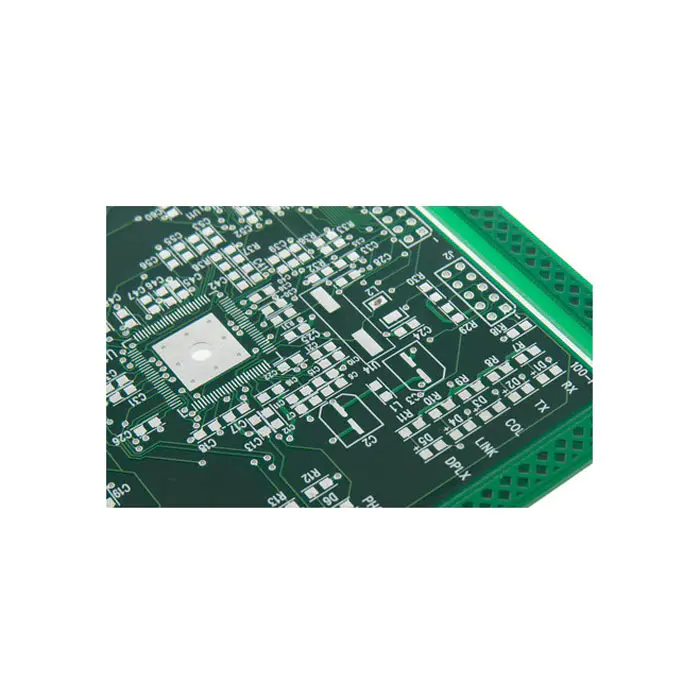

Copper is the commonest coating due to how nicely it features as an electrical conductor. Once the copper base plating is applied, a protecting solder masks is usually utilized, followed by the last silk-display to mark out all the parts on the board. Most generally, they're utilized by designers to create PCB modules, similar to Wi-Fi or Bluetooth modules, which will then be used as an impartial part to be placed onto another board in the course of the PCB meeting process.

Drilling is a substantial a part of the cost of a by way of-gap printed circuit board. Printed circuit boards are utilized in all but the simplest electronic products. They are also utilized in some electrical merchandise, such as passive swap bins.