Company Advantages1. Through the analysis of the structure and materials, altium through hole pad with low cost and long service life has been developed. Its working panel is coated with a photo-sensitive epoxy-based ink, which can ensure its insulation resistance

2. People can take it everywhere they go. It is lightweight and adds no extra burden to people's luggage or bags. It is widely used in different electronics industries, such as telecommunication and consumer electronics

3. This product has good seams quality. Its seams are even, closely spaced, lying flat on its fabric and are not easy to burst. It has high tensile strength and can be deformed without breakage

4. The product has guaranteed durability. It has been lifted and dropped for thousand times to test the durability in case of heavy loading. It has increased power densities which guarantee its long service life

5. The product is not likely to fade. It has been tested by the dry and wet crocking test that requires it to be rubbed on the white fabric and dipped into water to check its fading level. It can reduce the electrical signal loss and provides the highest efficiency

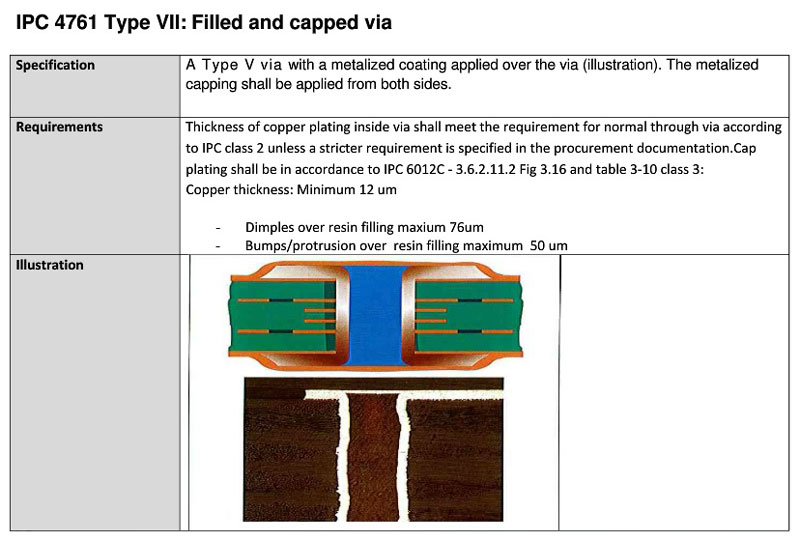

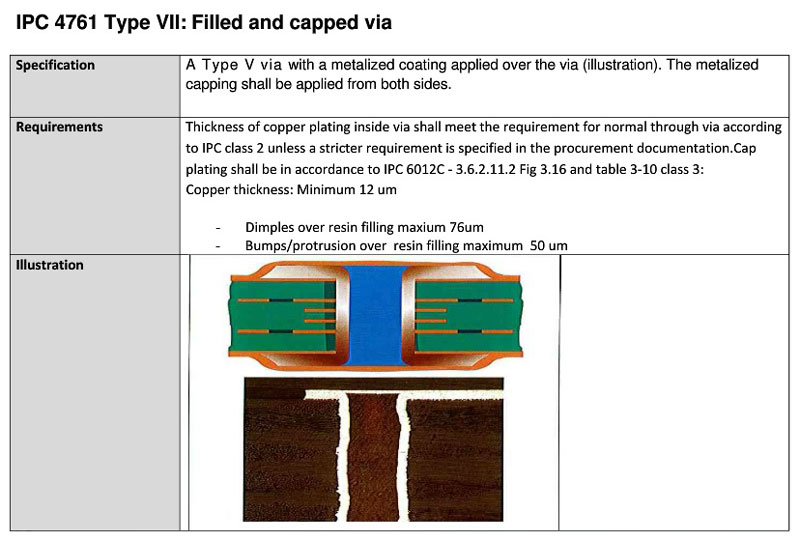

Via In Pad (VIP) technology refers to the vias in SMD pad or BGA pad due to small space for layout, in order to avoid the solder paste flow into inner layer or the other side in assembly production, basically this type of via need to be plugged with resin and plate copper over to cap the via to make it invisible.

Via in pad technology is widely used in high density PCBs, especially for the PCBs that require a limited BGA space and are focused on heat transfer and high speed design. Although blind holes and buried holes help increasing density and save space on the circuit boards, through holes are still the best choice for thermal management and high speed design elements.

The advantages of Via In Pad technology

● Suitable for fine pitch BGAs

● Improved thermal dissipation

● Provides a flat, coplanar surface for component attachment

● Leading to higher density of PCBs and promoting space saving

● Overcomes high speed design issues and constraints.

● Meets closely packed placement requirements.

The Via In Pad technology is defined in IPC standard with IPC-4761 VII

A-TECH manufactured lots of multilayer PCBs with Via In Pad designs Both in BGA Pads or in other SMD Pads, we’re able to plugged vias fully and then plated copper over to make the surface of pad as flat as other pads without dimples.

Company Features1. Established years ago, A-TECH CIRCUITS Co., Ltd. is one of the main manufacturers of press fit pins pcb in China with a solid industry background and related experience. Our company maintains a highly experienced and qualified professional team in our production department. They help the company to manufacture cost-effective quality products with the best delivery lead-time to meet order fulfillment expectations.

2. Our products have a good sale in Europe, the USA, Africa, and Japan. Over the years, we have developed many strategies partners and received their support and trust.

3. We have shipped products across China and to other countries, including America, Australia, Japan, and South Africa. The accumulated extensive knowledge of the quality standards and market needs of these countries promotes our exporting business. A-TECH will adhere to the firm belief of becoming an international altium through hole pad exporter. Inquire!