Company Advantages1. The production process of A-TECH via in pad technology is strictly carried out. It has passed through cleaning, mounting, welding, surface treatment, and quality checks.

2. Our professional and skilled quality controllers carefully inspect the product at every step of the production process to ensure that its quality remains excellent without any defects.

3. A series of strict pre-delivery testing is carried out to eliminate the defect product. The testing is strictly conducted by our testing personnel and thus the quality of this product can be guaranteed.

4. There is always a positive side when buying this garment. It lasts longer and can be passed on. So there is the option of selling it if it is still in a good condition or donating it to the needy when one wants to update their wardrobe.

5. The fit of this garment has the ability to make people feel confident, energized, and attractive in day to day situations.

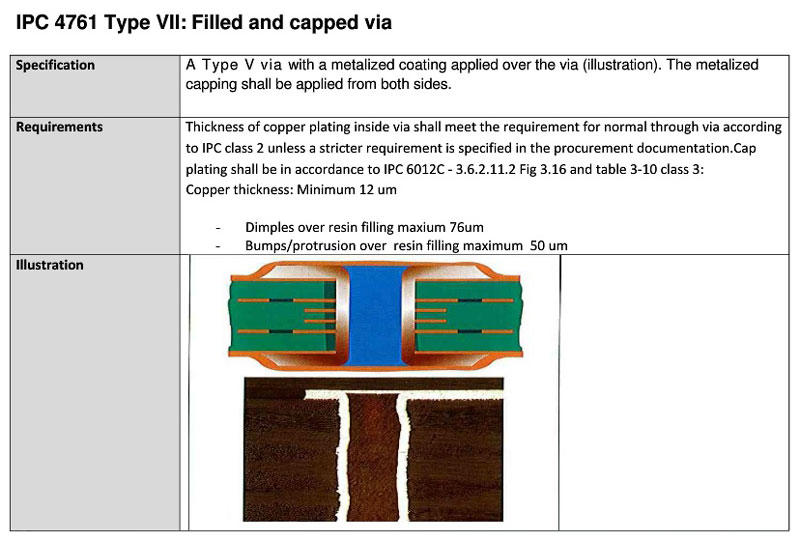

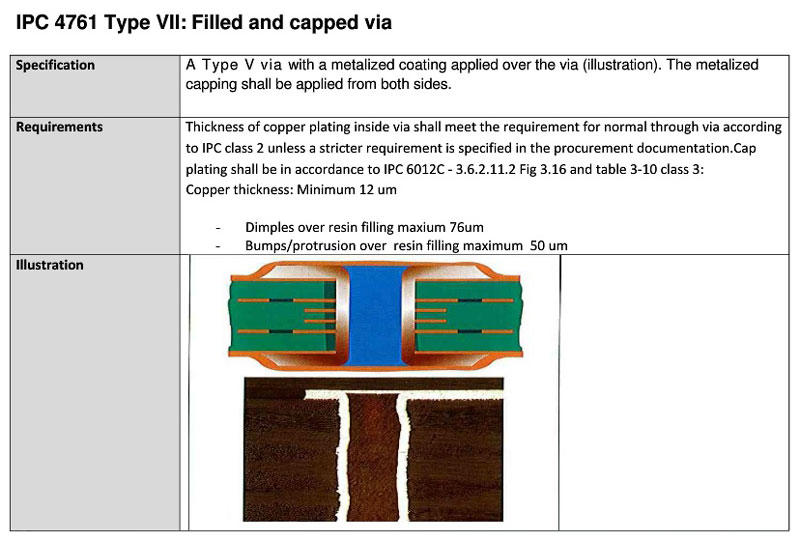

Via In Pad (VIP) technology refers to the vias in SMD pad or BGA pad due to small space for layout, in order to avoid the solder paste flow into inner layer or the other side in assembly production, basically this type of via need to be plugged with resin and plate copper over to cap the via to make it invisible.

Via in pad technology is widely used in high density PCBs, especially for the PCBs that require a limited BGA space and are focused on heat transfer and high speed design. Although blind holes and buried holes help increasing density and save space on the circuit boards, through holes are still the best choice for thermal management and high speed design elements.

The advantages of Via In Pad technology

● Suitable for fine pitch BGAs

● Improved thermal dissipation

● Provides a flat, coplanar surface for component attachment

● Leading to higher density of PCBs and promoting space saving

● Overcomes high speed design issues and constraints.

● Meets closely packed placement requirements.

The Via In Pad technology is defined in IPC standard with IPC-4761 VII

A-TECH manufactured lots of multilayer PCBs with Via In Pad designs Both in BGA Pads or in other SMD Pads, we’re able to plugged vias fully and then plated copper over to make the surface of pad as flat as other pads without dimples.

Company Features1. As a renowned

impedance control pcb supplier, A-TECH excels in producing high quality edge plating pcb .

2. A-TECH CIRCUITS Co., Ltd. owns professional team of experienced curtain wall production and processing engineers and designers

3. Undertaking corporate social responsibility has become increasingly important to our company. We attach great importance to human rights. For example, we are determined to boycott any gender or ethnics discrimination by empowering them equal rights. Check now! With our ability to manufacture via in pad pcb , we can help. Check now! We aim to be creative problem solvers when confronted with challenges. That is why we will continue to work hard to create new creativity, try to solve impossible things, and surpass expectations. Check now!