Company Advantages1. The manufacturing process of A-TECH press fit pins pcb is rather complex and needs special workmanship, covering up to more than 50 process steps. The product is certified under UL(E357001) and RoHS

2. This product is easier to care for and wrinkle resistant to some extent. And it has the added plus of getting softer with each wash. Its solder mask can be offered with green, blue, white, black, yellow, and red colors

3. The product is not susceptible to the damage caused by overload and overcurrent. It is built with a heating element protection system which can effectively guard against malfunction. It has high tensile strength and can be deformed without breakage

4. The product features the desired safety. It can perform tasks in hazardous environments where humans are unable to operate. It has low water absorptivity in the damp environment

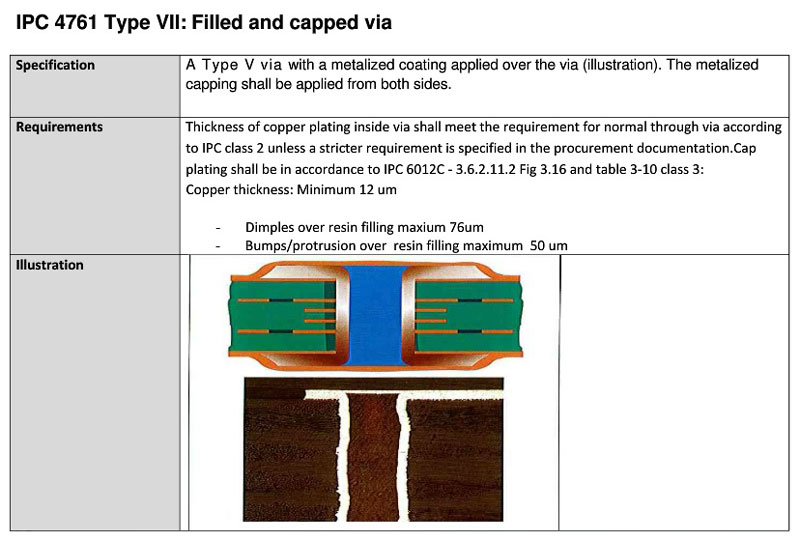

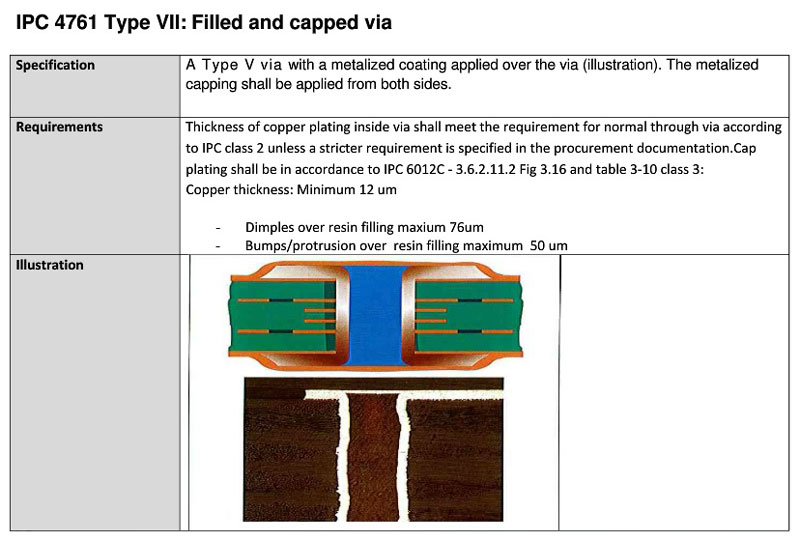

Via In Pad (VIP) technology refers to the vias in SMD pad or BGA pad due to small space for layout, in order to avoid the solder paste flow into inner layer or the other side in assembly production, basically this type of via need to be plugged with resin and plate copper over to cap the via to make it invisible.

Via in pad technology is widely used in high density PCBs, especially for the PCBs that require a limited BGA space and are focused on heat transfer and high speed design. Although blind holes and buried holes help increasing density and save space on the circuit boards, through holes are still the best choice for thermal management and high speed design elements.

The advantages of Via In Pad technology

● Suitable for fine pitch BGAs

● Improved thermal dissipation

● Provides a flat, coplanar surface for component attachment

● Leading to higher density of PCBs and promoting space saving

● Overcomes high speed design issues and constraints.

● Meets closely packed placement requirements.

The Via In Pad technology is defined in IPC standard with IPC-4761 VII

A-TECH manufactured lots of multilayer PCBs with Via In Pad designs Both in BGA Pads or in other SMD Pads, we’re able to plugged vias fully and then plated copper over to make the surface of pad as flat as other pads without dimples.

Company Features1. Based in China, A-TECH CIRCUITS Co., Ltd. has built a good reputation in the global market. We mainly focus on the production of heavy copper pcb . Our company has excellent production teams. They master the latest global product trends and new techniques in product manufacture. They are able to make sought-after models.

2. We have an advanced manufacturing plant which is strategically located with convenient transportation. This allows us to respond efficiently and flexibly to consumers and customers’ needs.

3. Relying on the research and development and manufacturing ability, as well as lots of advantages we have achieved over the years, we have won the praise and trust from partners around the world. A-TECH gets wide trusts and respect for excellent press fit pins pcb and press fit pins pcb. Contact us!