Company Advantages1. The manufacturing of A-TECH

edge plating pcb castellation covers a few aspects. They include metal cutting, forming, structure shaping, surface polishing, mechanical components' fabricating, an so on. It is 100% produced in accordance with IPC-6012 & IPC-A-600F standards

2. The product is very suitable for people seeking new ways that enhance their bathroom experience - esthetically, technically and experientially.

3. Features like edge plating pcb castellation say that

countersink pcb has a good competition capacity and a good development prospect. It is widely used in different electronics industries, such as telecommunication and consumer electronics

4. countersink pcb is an automatic edge plating pcb castellation device and very easy for press fit pins pcb . It stands out for its impact endurance performance

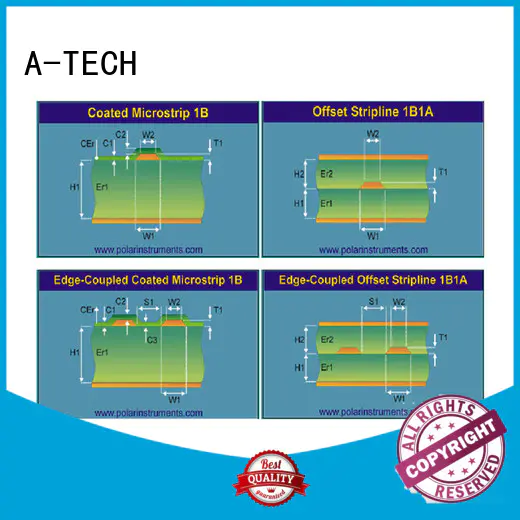

Impedance is the combination of the capacitance and inductance of a circuit when operated at high frequency. Control impedance in printed circuit boards are used across a broad range of applications to help ensure high signal integrity. Basically there are usually three types of impedance in PCB designs like single-ended impedance, differential impedance and coplanar impedance.

The factors affect impedance include: impedance trace width/spacing, copper thickness, dielectric thickness on either side of the impedance traces, dielectric constant of the core and prepreg material etc.

The applications of impedance control PCB include RF communication, Signal processing, High quality analog video, Computing 100MHz and above, Telecommunications and so on.

A large proportion of multilayer PCBs that A-TECH manufactured are with impedance control requirements, normally we will calculate impedance based on stack up and gerber designs to match with specified impedance values, our engineering dept might do necessary adjustments on stack up or impedance trace width/spacing if there is any mismatch after calculation. Moreover, the impedance coupons will be placed in each working panel which use for testing impedance values before shipment.

Company Features1. Based in China, A-TECH CIRCUITS Co., Ltd. is a rapidly growing enterprise which focuses on manufacturing and exporting quality edge plating pcb castellation . Our professional R&D team members are the core of our business. Over the years, they have been constantly improving the quality and performance of products and meeting the challenging needs of our customers.

2. We continually invest in the most advanced manufacturing facilities and technologies. These facilities and technologies give us the capacity to manufacture quality products per year.

3. We have a team of professional engineers. They are able to draw from their deep understanding of manufacturing to offer complete design services and engineering services. Service is such an important part that will never be neglected for A-TECH CIRCUITS Co., Ltd.. Please contact.