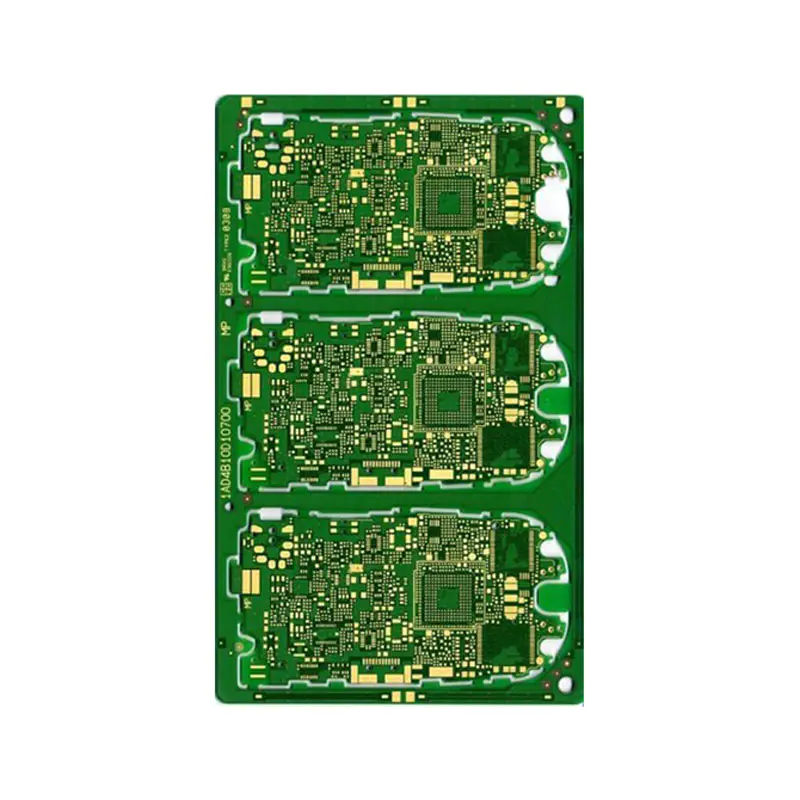

Why Are Printed Circuit Boards Usually Green In Color?

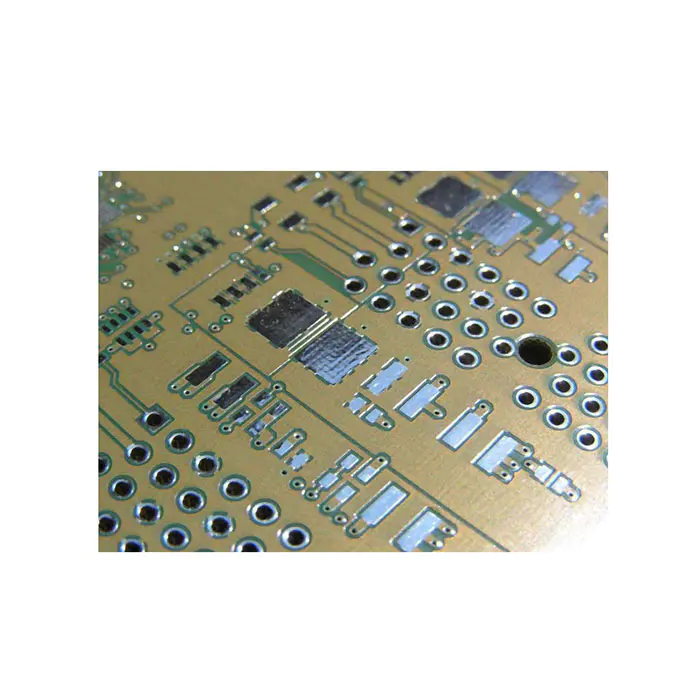

The nickel layer protects the copper from oxidation, and the gold layer protects the nickel layer. This dramatically will increase the resistance to corrosion and in addition maintains a flat surface which is crucial for assembly of leadless components. ENIG utilization has become quite common now because of the accountability for lead-free regulations. Due to the increased demand for improved performance of electronic functions, floor finishes have additionally been upgrading. Because of tighter PCB topography the HASL floor finish is rapidly being changed by gold-based surface finishes like ENIG, ENEPIG, and delicate/hard gold.

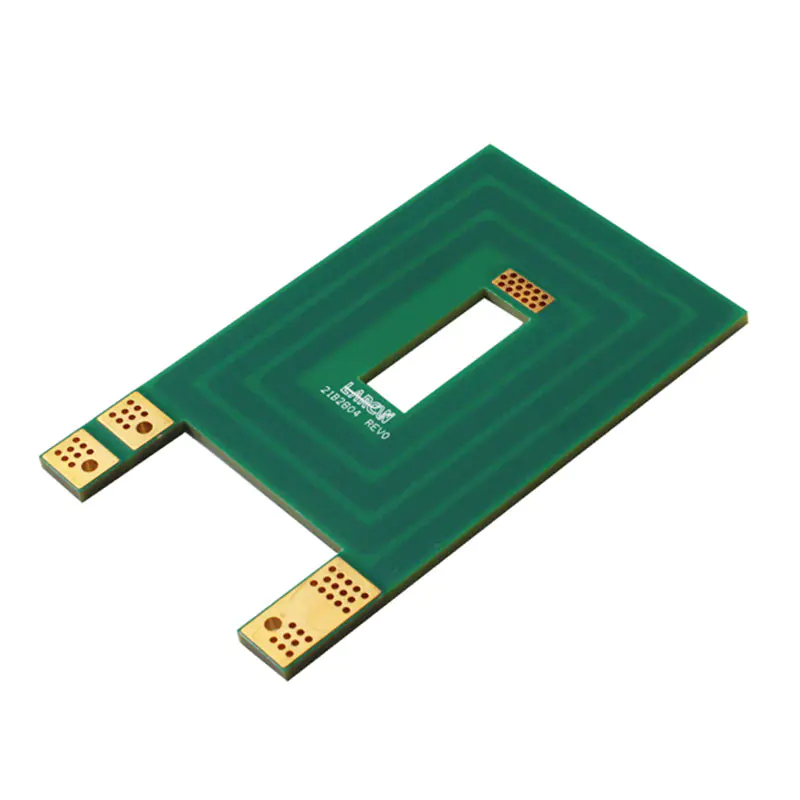

The finest options of utilizing an ENIG Surface Finish is its flat surface and glorious solderability. The Electroless Nickel is an auto-catalytic course of that deposits Nickel on a Palladium catalyzed Copper floor. The floor end impacts the PCB cost, the manufacturing course of, the standard, and the reliability of the product.

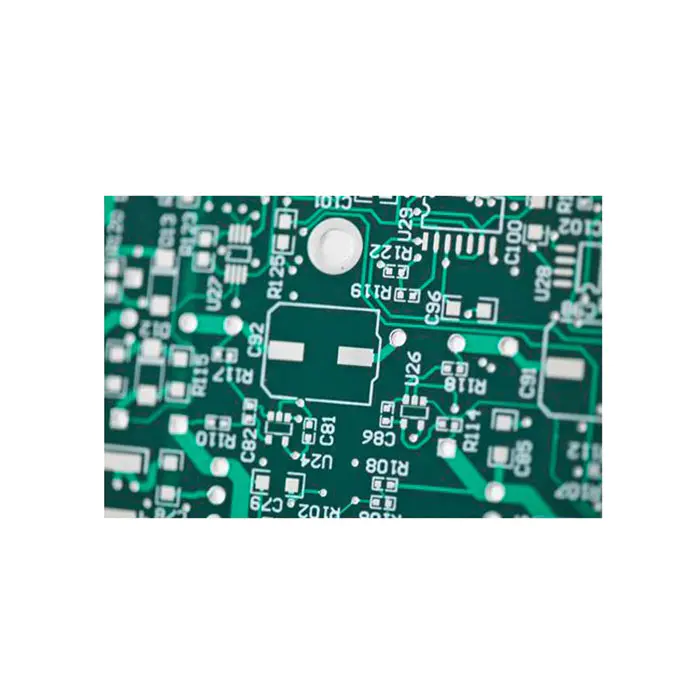

This concern with solderability increases after the first reflow cycle or long term storage of the PCBs. OSP is a superior PCB Finsih over traditional HASL, significantly for PCB meeting, in regards to co-planarity and solderability. However, it does require a significant process change with the type of flux and variety of warmth cycles necessary. Also, careful handling is very important given the degrading affects the acid from fingerprints have on the OSP, thus potentially leaving the copper susceptible to oxidation.

The features and benefits that made HASL a great selection prior to now simply cannot examine to the improvements of the other floor finishes. The PCB surface finish with ENEPIG may be very thin (between zero.05μm and 0.1μm), making the assembly and soldering process quite simple and positively more dependable when in comparison with ENIG. ENEPIG also has a long shelf life because of its durability and resistance from tarnishing.

If you could have any questions on PCBs otherwise you want to put money into newer know-how and PCBs in your merchandise, get in touch with the experts at Streamline Circuits. This end has additionally been listed as being particularly troublesome for wave soldering after assembly. w exposed to elevated temperature, the skinny tin layer can often nearly fully be converted to SnCu intermetallic, leaving little or no tin for soldering.

When compared to different surface finishes, like onerous gold and gentle gold plating, ENEPIG has turn into more affordable in recent years. The value of the ENEPIG floor finish decreased as a result of the added palladium layer reduces the required thickness of the costlier gold layer.

The gold-based mostly floor finishes have lots to supply when it comes to features and benefits when used in applications. A PCB floor finish is crucial for a printed circuit board because it prevents the copper (uncovered traces, pads, holes and floor plains) from oxidation – a critical ingredient to high-stage utility performance. OSP board is the surface remedy of PCB copper foil in accordance with the requirements of RoHS instructions a process. It is called natural soldering movie, also known as a copper protector. Now that you simply perceive extra about this important element of a PCB, you can acquire better-high quality printed circuit boards.