Company Advantages1. A-TECH press fit pins pcb is required to go through various inspections. Its raw materials (ingredients and safety), abrasion resistance, hypoallergenic feature, and its physical properties (rigidity, tensile strength, etc.) will be carefully checked. It is vacuum-sealed, which can greatly reduce the bulk of the overall cargo

2. Because of its outstanding features and broad application prospects, this product has been highly favored by the majority of customers. Thanks to the up-to-date vacuum DES line, it is manufactured with fine traces and high density

3. The product is corrosion resistant. Its materials will form a layer of oxidation film which features toughness and high density after an electrical process. With a compact design, it is space-saving

4. The product features excellent durability. Its metal structure is exquisitely processed by oxidation, polishing, and plating, therefore it will not rust or easily break down. It is 100% produced in accordance with IPC-6012 & IPC-A-600F standards

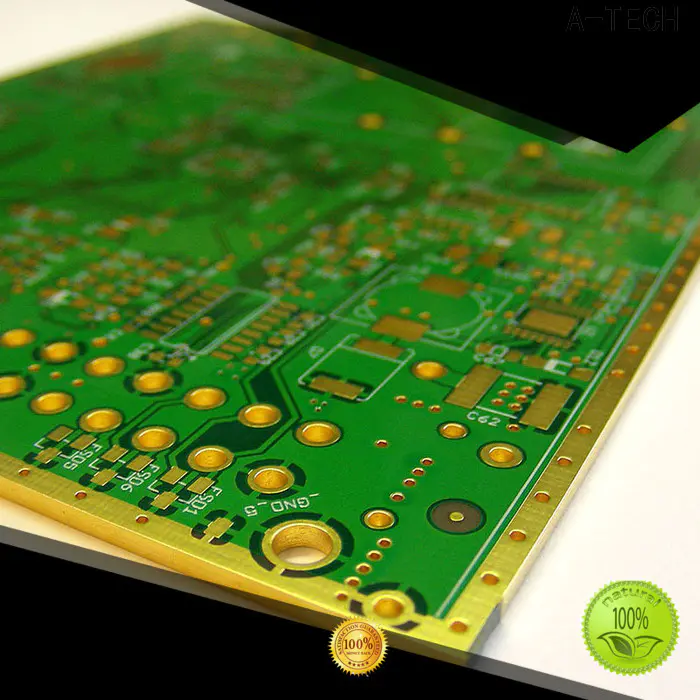

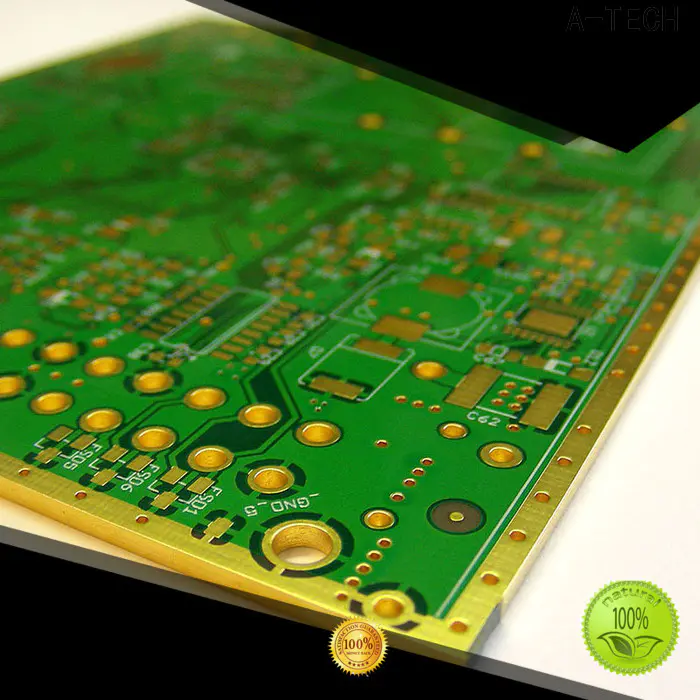

PCB edge plating, also called sideplating, it refers to copper plating that runs from top side to bottom side and runs along at least one of the perimeter edges. Portions of the printed circuit’s contour but also partial areas within the circuit board can be metalized.

In order to make PCB edges metalized, the printed circuit boards must be routed before through hole copper plated process, because the metallization of the PCB edges take place during this copper plating process. The ENIG (Immersion Gold) finish is preferred for PCB edges after copper plated.

PCB edge plating technology is used for several industries, especially in application that require better support function, such as:

● Edge connections and protection

● Edge soldering to improve fabrication

● Better support for connections such as boards that slide into housing connection

● Improving current-carrying capabilities for better EMC performance such as high frequency PCB

A-TECH has lots of manufacturing experience for PCB edge plating, and we’re able to control high quality for edge plating without burrs. Please try to contact our sales experts for any technical details.

Company Features1. A-TECH CIRCUITS Co., Ltd. has developed into a global company focused on annular ring pcb .

2. Our company houses a pool of candidates who are highly qualified in customer services. They have gone through professional training and are able to provide advice and are skillful in managing the negative emotion of customers.

3. We will practice sustainable development from now till the end. During our production, we will try best to reduce carbon footprint such as cutting wastes discharge and fully utilizing resources.