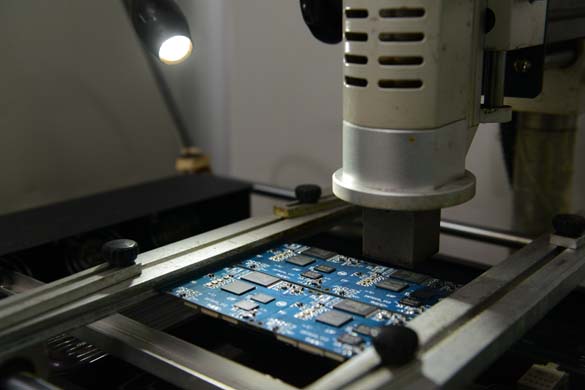

SMT Assembly Processing

Printed circuit board assembly processing (hereinafter referred to as SMT) The design of printed circuit boards is one of the important components of SMT patch assembly technology. The design quality of the printed circuit board is an important symbol to measure the technical level of surface assembly, and it is one of the primary conditions for ensuring the quality of surface assembly.

What is DFM?

DFM (Design for Manufacturing) is the most effective way to ensure the quality of PCB SMT processing. DFM is a design practice and process that matches the engineering requirements of a product with global manufacturing capabilities to achieve the lowest cost, highest output, and speed up time to market. DFM considers manufacturability and testability from the time of product development and design, so that the design and manufacturing are closely linked to achieve the goal of one-time success from design to manufacturing. DFM has the advantages of shortening the development cycle, reducing costs, and improving product quality. It is the way for enterprises to achieve success.

Traditional new product development methods are usually completed in stages of design, manufacturing, and sales. The traditional design method emphasizes the design speed when the product is first designed, and only focuses on the realization of the product function.In the design stage, the manufacturing requirements cannot be fully considered.As a result, due to the unmanufacturability or poor manufacturability, in order to correct the problems in the manufacturing process, Go back and do one or more redesigns, and each time you make improvements, you need to remake the prototype, which leads to a longer actual development cycle of the entire product and increased costs.

The modern design method emphasizes more detailed design when the product is first designed, and advances the problems that may occur during SMT patch processing and testing to the design stage to solve. Although this method takes more time in the initial design, the final result shortens the development and design time, and also reduces the cost of SMT patch processing. FASTPCBA's DFM statistical survey shows that 60% of the total cost of printed circuit board products depends on the initial design of the product, 75% of the manufacturing cost depends on the design instructions and design specifications, and 70% to 80% of the production defects are due to PCB design reasons of.

DFX related to SMT processing and manufacturing includes manufacturability design, testability design, analyzability design, assembleability design, environmental protection design, SMT processability design, logistics design, and reliability design.

Copyright © 2025 A-TECH CIRCUITS Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.