what is a pcb?

Printed circuit board)

Mechanical support for electrically connected electronic parts with the help of a conductive path, from lamination to non-

Conductive substrate.

Assembly, PCB design and quality control requirements in many electronics industries are set by standards set by IPC organizations.

The main general standard for printing circuit design is IPC-

2221A, regardless of the material used to make the circuit board.

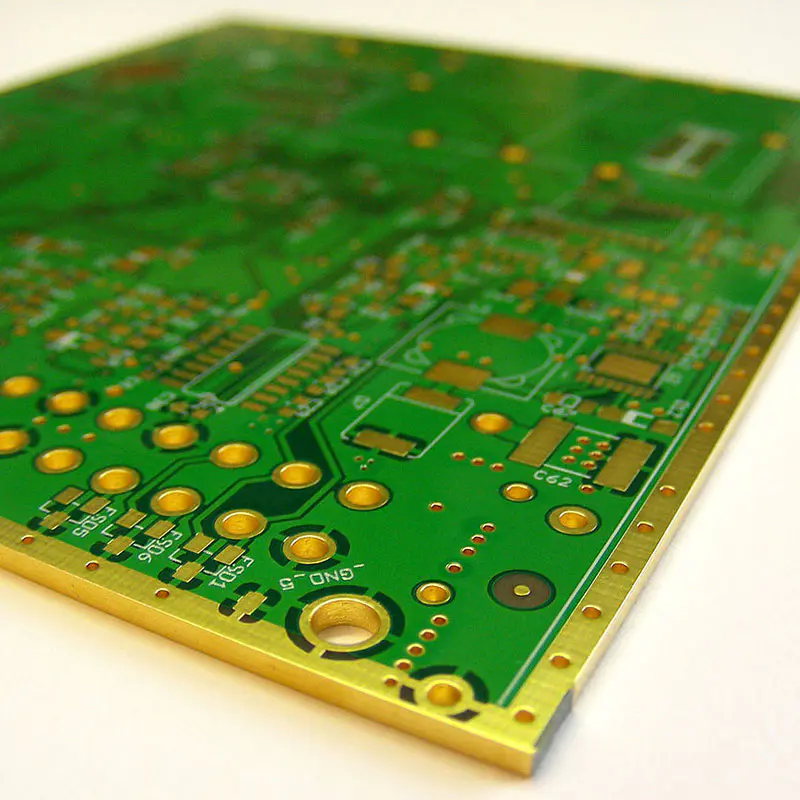

The circuit board consists of an insulator consisting of one or more layers of material glued to a single entity.

The additional layer acts as the ground of the circuit board.

Copper marks on the board are either produced by mechanically laying individual lines, or by applying the entire board to copper and stripping off the excess parts.

By stripping the excess part, leaving the required printed circuit to connect the electronic part.

Many printed circuit board stores can help with the design process and provide high-end features such as automatic routers and tracking optimizers, which can greatly reduce layout time.

However, the best result of the layout of the board is achieved at least through some manual wiring.

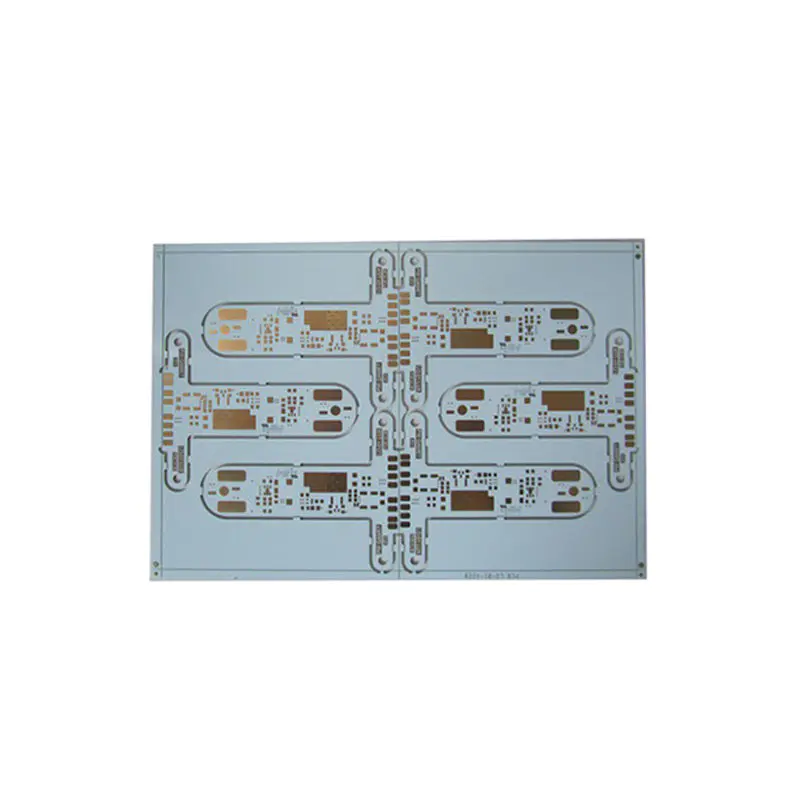

Nowadays, there are various boards to choose from for materials and finishes, including FR4, FR4 high temperature, pi, GeTek, Rogers, Arlon, Nelco, alumina, ceramics, plywood, FR1, CEM1, CEM5.

The thickness of the circuit board varies depending on the number of layers and can be as thin as 1. 0mm (0. 0394\").

They can be single-sided or multi-layered.

Wear layers with 1-Cooperoz or higher.

While this is the standard pcb on the market, you can get a custom board to suit your needs.

The key is to find the right PCB manufacturer to make the board according to your specifications.

Custom PCB can be manufactured in many ways.

For example, the design of a flexible circuit board is very flexible.

This allows the board to be placed where it is otherwise impossible to place or use for the wire system.

PCB can also be used for satellites, spacecraft and other machines in outer space.

Rigid copper cores are designed in such a way that heat is removed from sensitive components and protected at the extreme temperatures they experience.

Some circuit boards are designed to have an internal conductive layer that transmits power to individual components without using additional traces.

These customized needs are boards ordered by the company to meet the specific needs of limited space.

In addition, students and electronics enthusiasts also use pcb in custom projects and applications.

Cost advantage *

Efficient and reliable.

* High economy

Mass production.

* There is color code for different connections, so it is easy to install.

* Mention equipment ratings that help maintain equipment.

Disadvantages * More layout efforts.

* Higher initial cost compared to point-to-

Circuit or wire constructed by point-wrapped.

* The etching of the circuit board produces chemicals that are dangerous to the environment.

* Cannot be updated after printing.

There are PCB prototypes and low volume PCB on the market, the price is cheap and can meet most of the demand.

Today, free PCB software can be easily found online.

Amateurs are simple to use and efficient for professionals.

The PCB board is specially designed for each circuit, making the structure very easy.