Surface Finish

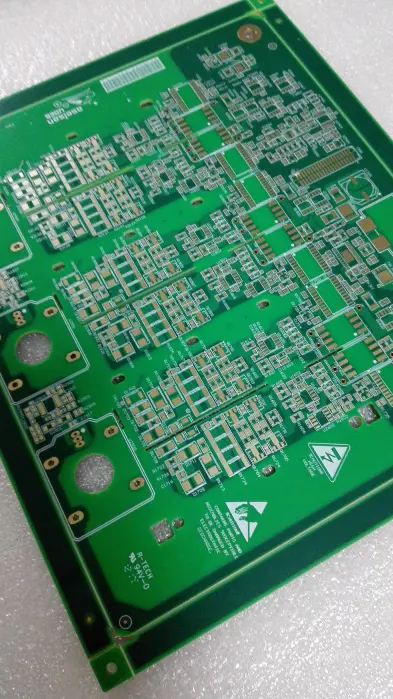

However with any stress and even vibration the parts could easily pop off without warning resulting from a brittle fracture at the interface. There are theories about phosphorous levels in the nickel plating solutions being off-spec and causing intermetallics during the gold plating. The oldest PCB used finishes are 60Sn/40Pb solder (easily soldered at moderate temperatures but lead-containing) and OSP (very flat SMT pads however short shelf life).

One of the downsides of HASL is that it leaves uneven surfaces and isn't suitable for nice pitch parts. Another draw back is that HASL just isn't lead-free except requested and having a unique process in place.

HASL is split into two types, and there are two varieties because one contains tin with lead and the other accommodates tin without lead. HASL is also one of the least costly types of PCB surface finishes out there. This means entry to this floor finish is broadly obtainable and it is also very economical. Soft gold end is used for boards designed principally for functions that require wire bonding, high solderability and weldability.

After the board has been dipped on this alloy, it is eliminated and put beneath air knives. These units then blow scorching air over the board’s floor to remove any excess materials. In different words, it attaches to the Nickel by changing atoms of Nickel with atoms of Gold. The purpose of the immersion Gold layer is to protect the Nickel floor and keep its solderability.

These have been the mainstay of the industry so processing equipment, solder pastes, fluxes, solder masks, and even stencil inks had been designed to deal with those processing profiles. The surface finish of your printed circuit board may not be the primary design side that you simply tackle in a new layout but it should be among the prime contenders. However, just lately, producers have realized it does have limitations. While HASL could also be low-price, the rise of improved floor mount technologies have exposed some shortcomings.

There are other lead-free choices that probably makes more sense for a high-reliability product. If a lead-free surface end is required you might wish to attempt to use Lead-Free HASL. HASL makes element soldering very efficient, however due to the thickness of HASL coating, the planarity of the floor could also be unsuitable for nice-pitch elements. To create a HASL floor end, a board is submerged in molten solder (tin / lead). The solder then covers all of the uncovered copper surfaces on the board.

Upon leaving the molten solder, high pressure hot air is blown over the floor through air knives, this ranges the solder deposit and removes the excess solder from the board floor. Hot Air Solder Leveling (HASL) is one of the mostly used surface finishes within the business.

Soft gold produces a a lot stronger welded joint when compared to hard gold. Depending on applications, printed circuit board technologies use gold extensively. Gold has good electrical conductivity, tarnish resistance, solderability after storage, and being excellent etch resist. A floor end is important for making a reliable connection between the PCB and the digital element.

A floor end has two major capabilities, to provide a solderable surface for enough soldering elements to the PCB, and to protect any uncovered copper from oxidizing. This end is often produced from organic preservatives that stop the copper surface of a PCB from oxidizing. A skinny layer of OSP is placed immediately over the PCB to protect it earlier than it gets soldered to a different system. To make this surface finish, manufacturers immerse a circuit board into a pot of a molten alloy, often comprised of tin and lead. In a lead-free HASL, different supplies exchange the lead within the liquid alloy.