Company Advantages1. The novel design of

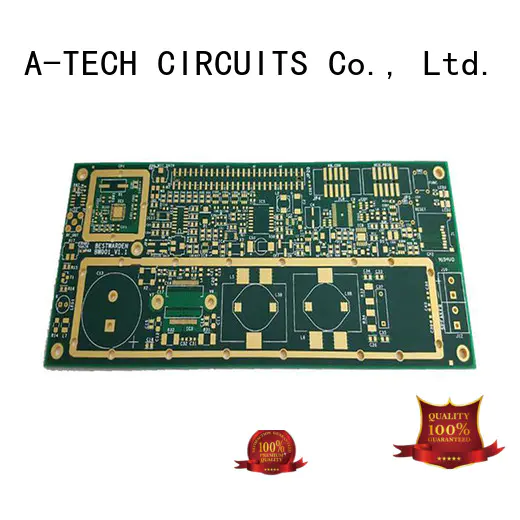

flexible pcb plays an increasing role owning to homogenization of other products at market. It has increased power densities which guarantee its long service life

2. A-TECH CIRCUITS Co., Ltd. works hard to achieve a win-win situation with customers. It is extremely popular in the markets of Europe, North America, and Asia

3. The product features excellent color fastness. There are no excessive dyes being deposited on the fabric surface to affect the firmness of the fabric's colorfastness. It is lead-free and environmental-friendly and has passed SGS test

4. The product has the advantage of enough resilience. An amount of filler has been decreased to improve the resilience of this product. Its working panel is coated with a photo-sensitive epoxy-based ink, which can ensure its insulation resistance

5. This product is strong and tough. It is sintered under very high temperature, which makes its physical properties to be optimized. Its solderable surface is protected from the oxidation

Quick turn PCB prototype manufacturing is one of characteristic service in A-TECH with special sample team to follow the whole production schedule. We fully understand short and accurate lead time is essential in today’s rapidly changing market place. Customers need to know the exact date of the circuit boards delivery so they can prepare the project schedules ahead of time.

We calculate and control each manufacturing process in the unit of hour to ensure the minimum time wasted in production. Currently the fastest lead time we can achieve for prototype PCB is 24 hours delivery for double sided PCB, 48 hours for 4 to 6 layers and 72 hours for 8 or more high multilayer PCB.

Moreover, we're different with most of prototype pcb manufacturers with online orders, whom 100% follow the gerber files you submit online to build, no matter it’s correct or there are some errors on design. Our engineering group offer DFM (design for manufacturing) service before manufacturing, we'll submit engineering questions to confirm and communicate with customers to optimize designs or avoid any potential errors.

| The standard and fastest lead time for prototype PCB in A-TECH |

| Layer | Fastest Lead Time | Standard Lead Time |

| 2 | 24 Hours | 4 WDs |

| 4 | 48 Hours | 5 WDs |

| 6 | 48 Hours | 6 WDs |

| 8 | 72 Hours | 7 WDs |

| 10 | 96 Hours | 8 WDs |

| 12 | 96 Hours | 8 WDs |

| 14 | 120 Hours | 9 WDs |

| ≥16 | Up to difficulty | Up to difficulty |

Company Features1. All staff from A-TECH CIRCUITS Co., Ltd. are well-trained for best flexible pcb . Our design team is equipped with years of experience. Their design analysis services can help customers get to market first, reduce development costs and improve overall product quality.

2. We have recently built up a supply chain management team. They have deep knowledge of manufacturing, warehousing, logistics, and transportation as well as customer service. This enables them to align production plans to deliver products in a cost-effective and targeted way.

3. Our company has many product experts. They can meet product requirements in a short amount of time due to their experience and expertise in this field. We are working hard to build an environmental-friendly business model that respects man and nature. This model is sustainable, which helps lower our carbon footprint.