Company Advantages1. A-TECH vippo pcb goes through rigorous inspections and quality controls to ensure quality. From raw materials to finished goods, our inspection team eliminates defects and non-compliance during different stages of the production process. Being laminated by advanced vacuum lamination equipment, it has a uniform dielectric thickness after lamination

2. This product is widely used in the market for its excellent characteristics and significant advantages. It is 100% produced in accordance with IPC-6012 & IPC-A-600F standards

3. The product performs well in heat resistance. The materials used in it have a high coefficient of heat conductivity and a relatively low coefficient of linear expansion which make it not prone to fracture under high temperature. The product has the performance of great stability

4. The product has a fine melting point. It is an optimized refractory material which can prevent it have a reaction with the molten materials. It can reduce the electrical signal loss and provides the highest efficiency

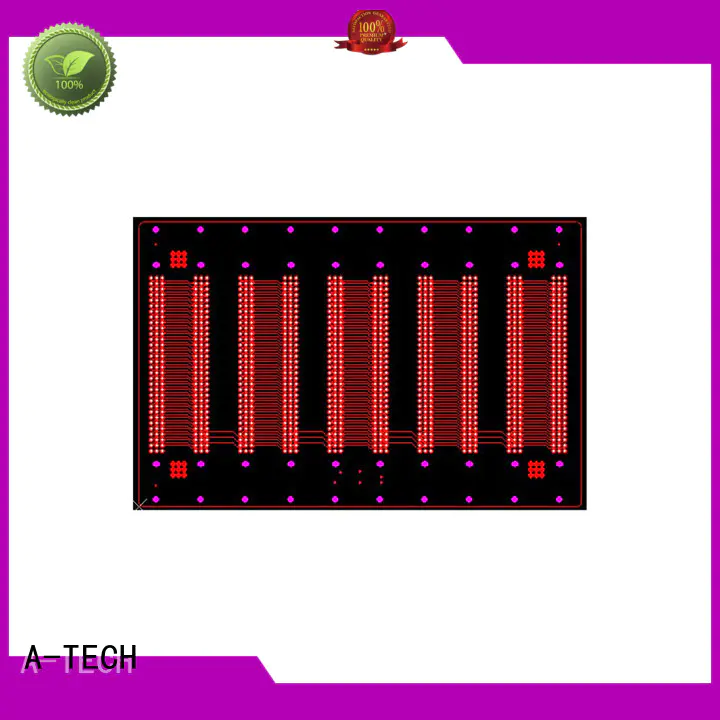

Press fit hole PCB, or called press fit pins PCB, they’re component holes with copper plated through and with tighter tolerance than standard PTH, the tolerance of standard PTH is +/-0.075mm(3mil), but the tolerance of press fit hole is normally +/-0.05mm(2mil).

Press fit holes are used as holes to fit the leads of connectors that will not be soldered but pressed into the holes. In order to accommodate lead and hole to tightly fit together, the tolerance on both are well defined, the typical tolerances for the press fit holes depends on the type of connector that is used and it’s the connector manufacturer who specifies this.

Press fit technology reduces PCB assembly time and effort considerably, and press fit pin eliminates the need for soldering, this cuts process time and cost, and boosts production output capacity. With no need to solder modules, engineers enjoy great flexibility in design. The module can easily be mounted on top or bottom of the PCB at no extra cost and effort.

A-TECH drill press fit holes with new drill bits and control specially in manufacturing process to ensure finished hole size within tolerance as specified.

Company Features1. A-TECH is a renown brand thanks to the top ranking

countersink pcb and excellent service.

2. We forge close partnerships with global customers. The constant and intimate interaction allows us to evaluate their needs better and to tailor products and services accordingly.

3. We believe in Quality Service and our approach has been designed to provide the same. We listen carefully to our clients and provide space, time and materials according to an agreement for the project. Ask!