Osp Process Of Pcb Board

A secondary problem for this connector is bridging however this was not the scope of this case research. A DDR3 connector is usually used in computer expertise for board to board connections.

In addition, with applied sciences pushing the boundaries of RF frequencies further in sensors and radar, I predict that these extra unique PCB finishes are going to turn into more prolific sooner or later. As RF frequencies enhance to 60 GHz – eighty GHz, the PCB end has a greater significance to the efficiency and performance of the PCB, changing into an important a part of the overall design performance. Copper, gold and silver all provide very low resistance and insertion loss; nonetheless naked copper is, after all, not suitable as a end as it's going to degrade, equally (but to a lesser extent) to silver. Apparently, folks with totally different positions have different choice standards. No matter what sort is chosen, it solely caters to the necessities and comfort of individuals with few issues in regards to the high quality, performance and reliability of PCBs and PCB meeting.

Solvents - added to facilitate processing and deposition to the joint. Solvents are usually dried out throughout preheating before the soldering operation; incomplete solvent removal may lead to boiling off and spattering of solder paste particles or molten solder. Low planarity on vertical levelers could make this surface finish unsuitable to be used with nice pitch components. The PCB is often dipped into a shower of molten solder so that all uncovered copper surfaces are covered by solder. A variant of this process provides a skinny layer of electroless palladium over the nickel, a course of known by the acronym ENEPIG.

Some metals are categorized as 'unsolderable' in air, and should be either coated with one other metallic before soldering or special fluxes and/or protecting atmospheres have for use. Such metals are beryllium, chromium, magnesium, titanium, and a few aluminium alloys.

Protective atmosphere with chemically lowering properties can be helpful in some circumstances. Molecular hydrogen can be used to cut back surface oxides of tin and indium at temperatures above 430 and 470 °C; for zinc the temperature is above 500 °C, where zinc is already turning into volatilized. (At lower temperatures the response speed is just too slow for sensible purposes.) Very low partial pressures of oxygen and water vapor should be achieved for the reaction to proceed. Fluxes for prime-temperature soldering differ from the fluxes to be used at decrease temperatures. High molecular weight hydrocarbons are sometimes used for this software; a diluent with a lower molecular weight, boiling off through the preheat part, is often used to aid software.

The chemical compounds used typically concurrently act as each autos and activators; typical examples are borax, borates, fluoroborates, fluorides and chlorides. Halogenides are lively at decrease temperatures than borates, and are subsequently used for brazing of aluminium and magnesium alloys; they're nonetheless extremely corrosive.

Conductivity - some fluxes remain conductive after soldering if not cleaned correctly, resulting in random malfunctions on circuits with high impedances. Different types of fluxes are in another way prone to cause these points. Activity - the ability to dissolve existing oxides on the steel surface and promote wetting with solder.

Using low melting level alloys can get rid of the degradation drawback of OSP and facilitate the general use of this finish. For each soldering temperature the soldering speed shall be stepwise increased ranging from 5mm/s. Selective soldering checks shall be performed on a Kurtz Ersa Ecoselect 1 machine with a normal SnCu primarily based alloy and the low melting point LMPA™-Q alloy. An Sn completed DDR3 connector was chosen because of its high pin density of 240 pins with a 2 mm pitch. This will permit for sufficient outcomes to evaluate the via hole wetting efficiency.

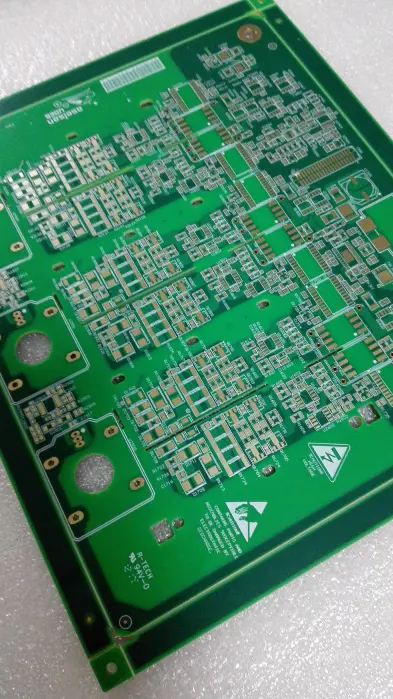

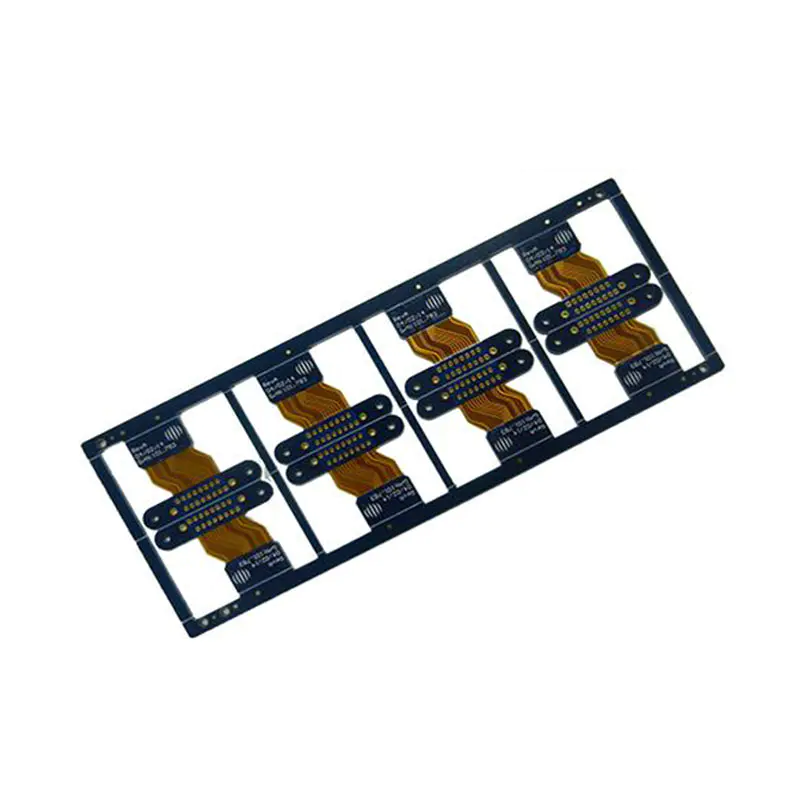

Flexible PCBs helps in decreasing the board size, which makes it ideal for various functions where excessive signal hint density is required. In the method of fabrication, it’s not allowed to instantly touch OSP PCBs with arms in order to avoid the oxidation on account of the contact of sweat. Thus, to be able to get hold of clean and even film thickness, it’s crucial to maintain the stability of micro etching speed. Generally speaking, it’s suitable to manage the micro etching velocity within the range from 1.0 to 1.5μm per minute. As prospects plates copied from the PCB, PCB design, prototype manufacturing, production, processing, and other SMT one-cease service.

Inorganic fluxes include parts taking part in the same function as in organic fluxes. They are more typically used in brazing and other high-temperature applications, the place organic fluxes have insufficient thermal stability.