Organic Solderability Preservatives

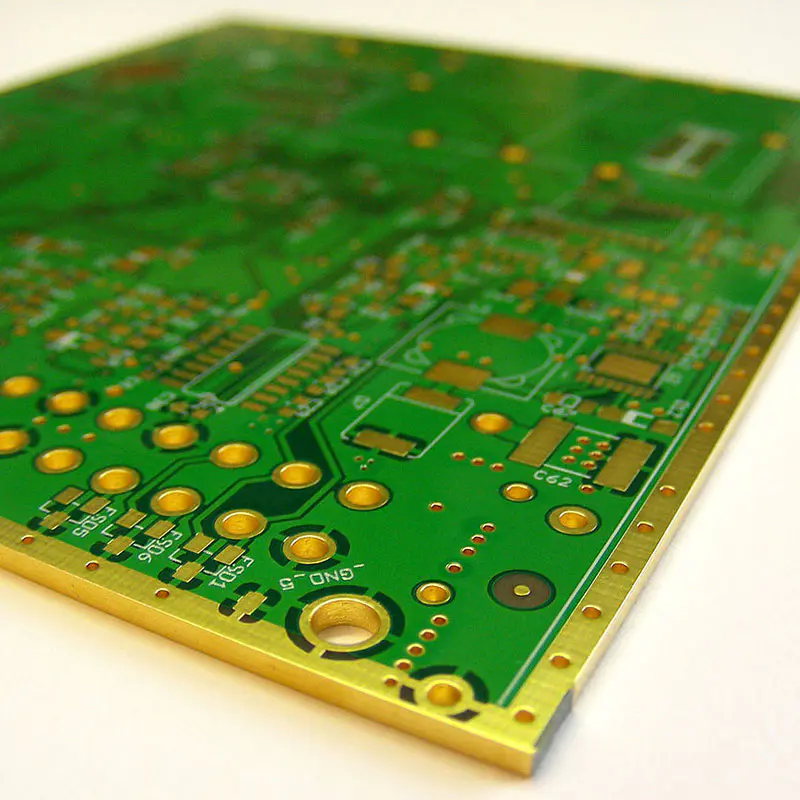

Whether that’s a screw being used or a board being by accident scratched during dealing with. These are stress elements which are as a result of manufacturing course of and plating chemistry. This is particularly true for an electroplated PCB finish which causes greater stresses than different plating processes. The welding energy of the OSP copper base is basically higher than that of the ENIG nickel base. All surface end strategies have their pros and cons; the decisive issue is, of course, their application.

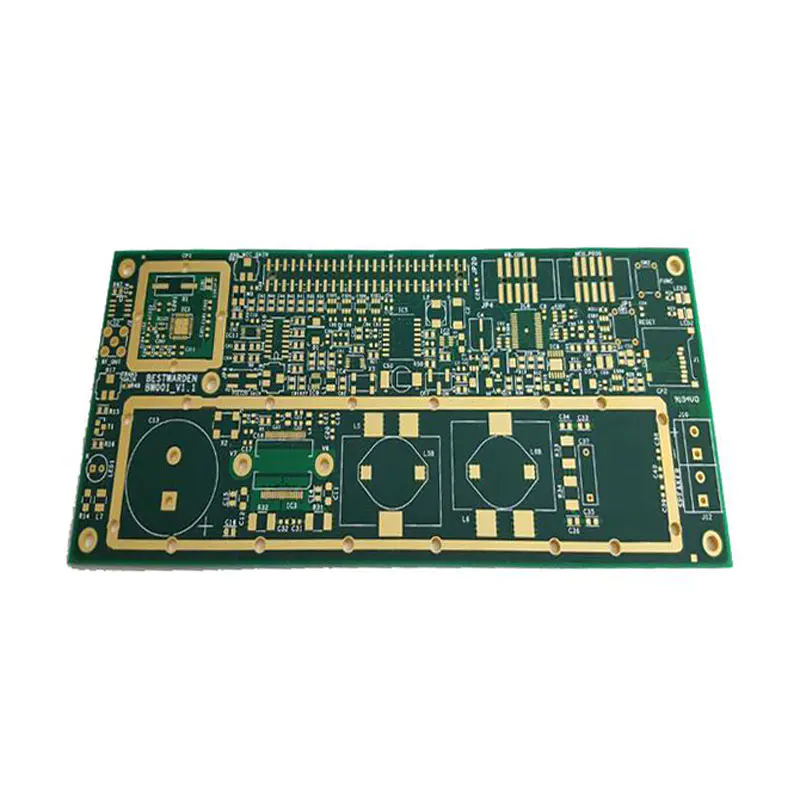

A double sided FR 4 board with an OSP coating commonly used in Asia was chosen as a test board. There are 1,001 suppliers who sells osp pcb meeting board on Alibaba.com, primarily positioned in Asia.

The top international locations of provider is China, from which the share of osp pcb assembly board provide is a hundred% respectively. The INGUN E-TYPE® FUSION take a look at probes based mostly on the established INGUN E-TYPE® technology and enables the highest contact reliability on the PCB with out subjecting it to excessive stress.

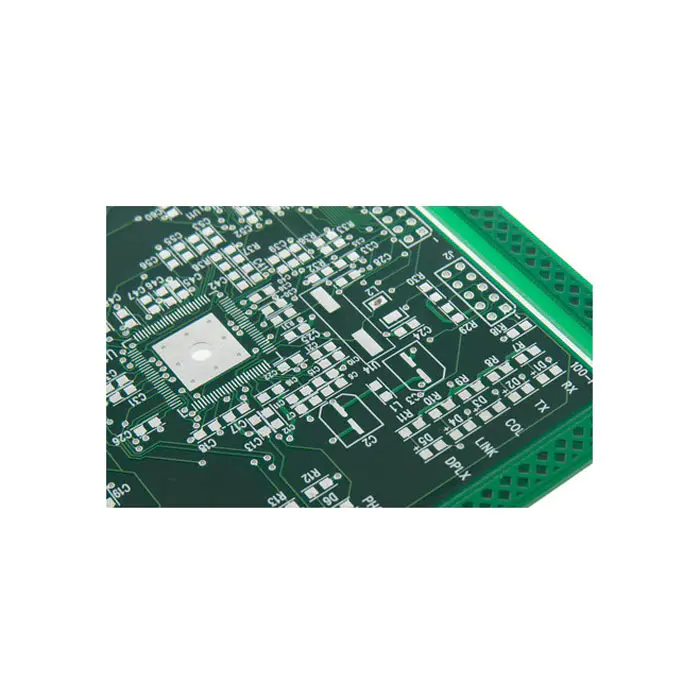

A short overview of the most common surface finishes is given below. Our employees is properly seasoned, and together with our sturdy network of suppliers & manufacturers, the AGS team becomes your advantage for superior printed circuit board options. The use of plasma cleansing of the conductive pad of a PCB could also be helpful at other stages in the process as well.

It is also onerous to tell apart whether or not a PCB board is coated OSP or not. , abbreviated as OSP, is known as anti-oxidants in the PCB trade. The common OSP composition includes alkylbenzimidazole, natural acids, copper chloride, deionized water, and so forth. There’s also the straightforward mechanical stress utilized to a circuit board during its typical manufacturing process.

The flatness doesn't allow the assembly of finely spaced components and the tin diffuses in the copper. 3.OSP requires a stronger Flux when soldering, in any other case the protecting film can not be removed which can lead to soldering defects.

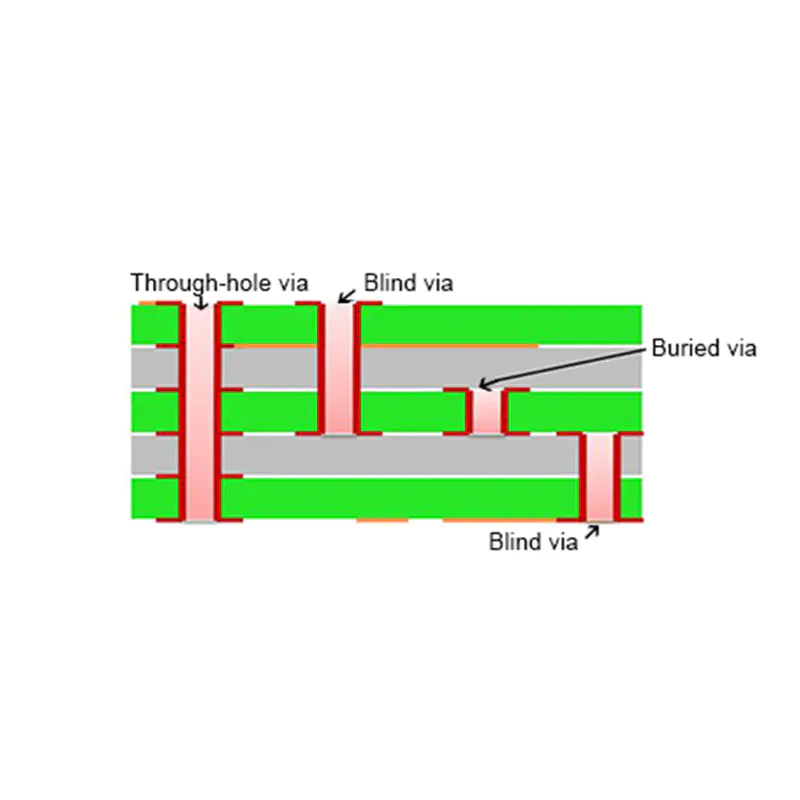

However, as the frequency will increase, present tends to cross extra on the outer surface/pores and skin of the track, so the plating and its conductive loss turns into of higher significance. You can discuss with article belongings you barely find out about OSP to get more details of OSP surface finish technology.

Hashimoto, A Study of Suitable Palladium and Gold Thickness in ENEPIG Deposits for Lead Free Soldering and Gold Wire Bonding, Uyemura, April 2009. Hard gold isn't normally applied to weldable zones due to its excessive price and its relatively low solderability. Tin plating is coming again and, within the quick time period, will in all probability be the preferred various end to ENIG for SMC purposes. This end is compatible with assemblies by press-fit connections and finely spaced component assemblies. The overall cost is excessive, solderability is lowered when the palladium layer is thick, and wettability just isn't excellent.

The resistance values are considerably lower than 50 mΩ, which permits precise measurement. Furthermore, measurements at these low resistance values exhibit solely slight fluctuations. The check probes in the INGUN E-TYPE® FUSION collection obtain a perfect compromise between sign high quality and reliable contact thanks to their options, which allow reliable contacting of powerful surfaces.

This provides a a hundred % larger contact drive when impacting the test surface, which is achieved by the elevated spring pre-load. The FUSION take a look at probes, nevertheless, have the same spring pressure at working stroke as a regular check probe (GKS), see image 6. The additional contact drive initially gained ensures dependable penetration of insulated top layers and a contact floor between probe and PCB which is as much as 25 % larger due to the penetration depth. The sign high quality chart (see image 3) shows the measurement accuracy achieved on each check point with OSP coating.

A-TECH CIRCUITS Co., Ltd. is trying to institute social good changes this relationship because it averts a firm's resources from its core task of increasing profits.

A-TECH CIRCUITS Co., Ltd. attaches great importance to customers and assists them in achieving their demands.

A-TECH CIRCUITS Co., Ltd. affords you a suitable low price for proving our ethical considerations.

A-TECH CIRCUITS Co., Ltd. provides the ideal conditions for business creation – access to cash, human capital and affordable office space, for instance – can help new ventures not only take off but also thrive.

Our company is professional in manufacturing pcb supplier especially pcb manufacturer in China.