The PCB boards used in LEDs are generally aluminum substrates. Why do LED chip processing choose aluminum substrates? What are the advantages and disadvantages of aluminum pcb substrates?

1. Introduction of Aluminum Substrate

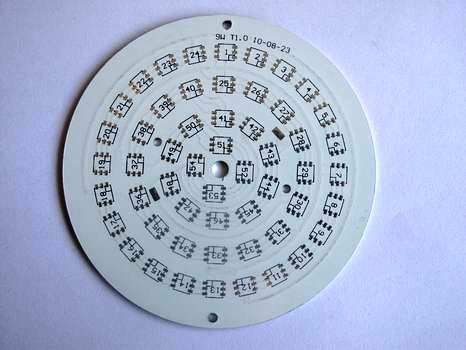

Aluminum substrate is a kind of metal-based copper clad laminate, which has good heat dissipation function. The ordinary aluminum substrate has a three-layer structure, which are a metal base layer, an insulating layer and a circuit layer (copper foil). The aluminum substrate designed by some high-end products is a double-sided board, and the structural layers are a circuit layer, an insulating layer, an aluminum base, an insulating layer, and a circuit layer. Multi-layer aluminum substrates are very rare.

2. The difference between aluminum substrate and ordinary circuit board

Aluminum substrate is also a kind of printed circuit board. The difference between it and the circuit board is mainly aluminum alloy, and the information of the ordinary circuit board is glass fiber.

3. The reason why the LED PCB uses aluminum substrate

When the LED lamp works, a lot of heat will be generated. Therefore, the circuit board of the LED lamp must consider the heat dissipation problem in the design. The biggest feature of the aluminum substrate is fast heat dissipation, so the circuit board used for LED lights is mainly an aluminum substrate.

4. Advantages of aluminum PCB substrate:

4.1. More compatible with LED PCB processing technology;

4.2. In the circuit design plan, it is extremely effective to stop the thermal diffusion, thereby reducing the operating temperature of the module, extending the service life, and improving the power density and reliability;

4.3. Reduce the assembly of radiators and other hardware, reduce product volume, reduce hardware and assembly costs;

4.4. Replace the fragile ceramic substrate to achieve better mechanical durability.

5. Defects of aluminum substrate:

5.1. Higher cost.

5.2. At present, the mainstream can only do single-panel, making double-panel process difficult.

5.3. The finished products are more prone to problems in terms of electrical strength and withstand voltage.

Aluminum PCB substrate can handle the technical problems of LED chip processing, but its defects also limit its development.

Copyright © 2025 A-TECH CIRCUITS Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.