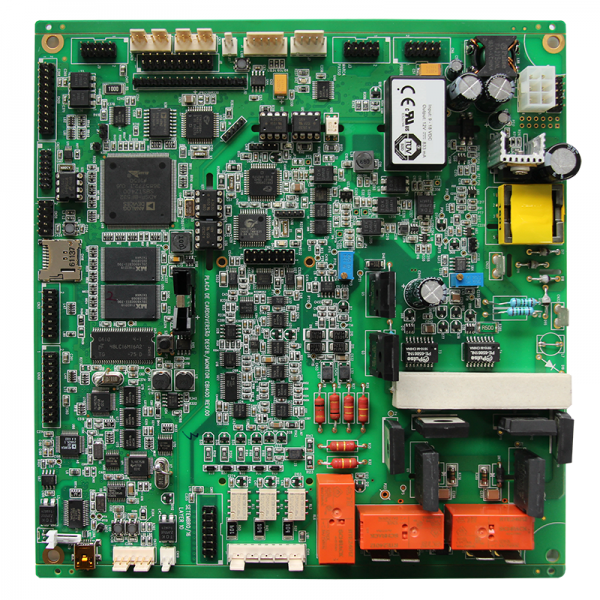

Surface Mounting Technolegy (SMT) is a new generation of electronic PCB assembly technology that will use traditional electronic components. The device is compressed into a device with a volume of only a few dozens, thereby achieving high density, high reliability, miniaturization and low cost of electronic product PCB assembly.

This miniaturized component is called: SMY device (or SMC, chip device). Assemble components for printing. The process on (or other substrate) is called the PCB SMT process. The related assembly equipment is called SMT equipment.

At present, advanced electronic products, especially computer and communication electronic products, generally use SMT technology. The output of international SMD parts has increased year by year, while the output of traditional devices has decreased year by year, so over time, SMT technology will become increasingly popular.

What are the characteristics of SMT technology:

High assembly density, small size of electronic products and light weight. The volume and weight of the chip component is only about 1/10 of the traditional plug-in component. After using SMT, the volume of electronic products is reduced by 40% to 60%, and the weight is reduced by 60%. 80%.

High reliability and strong anti-vibration ability. The defect rate of solder joints is low.

The high frequency characteristics are good. Reduce electromagnetic and radio frequency interference.

Easy to automate and increase productivity. Reduce costs by 30% to 50%. Save materials, energy, equipment, manpower, time, etc.

Why use SMT technology:

Pursuing the miniaturization of electronic products, the previously used perforated plug-in components cannot be reduced.

Electronic products are more complete, and the integrated circuits (ICs) used do not have through-hole components. Especially large-scale, highly integrated ICs must use surface-mount components.

Product ingredients, production automation, factories must produce high-quality products at low cost and high output to meet customer needs and enhance market competitiveness.

Development of electronic components, development of integrated circuits (IC), various applications of semiconductor materials.

Copyright © 2025 A-TECH CIRCUITS Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.