Importance Of Pcbs

The final coating, an immersion gold layer, retains the palladium from interacting with environmental contaminants that would in any other case impede soldering. OSP is likely one of the PCB surface finishes, means Organic Solderability Preservatives, which is utilized upon the bare copper to stop PCB from being oxidized.

OSP is RoHS compliant and may be quickly eliminated in the PCB assembly processing. OSP is not as sturdy as other surface finishes, similar to HASL or ENIG, and may be very sensitive to small abrasions, which means that careful handling with proper protecting equipment is required throughout the PCB Assembly Process. Due to the fragility of the OSP finish, we highly suggest choosing Bittele’s Complete PCB Assembly service for projects using OSP end; this manner, you'll be able to minimize the shipping and handling of your OSP-completed boards. Edge connectors, positioned along one fringe of some boards, are often nickel-plated then gold-plated.

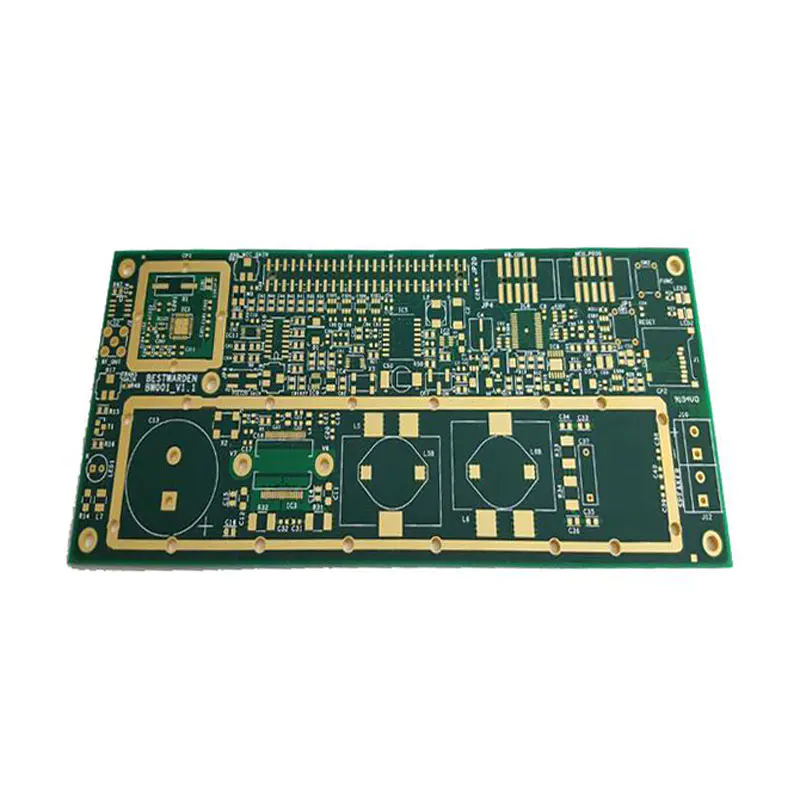

Surface mounting lends itself well to a high diploma of automation, lowering labor costs and significantly growing production charges in contrast with through-hole circuit boards. Surface mount elements can be about one-quarter to 1-tenth of the dimensions and weight of through-hole parts, and passive components much cheaper. The Nickel is the barrier to the copper and is the surface to which the parts are actually soldered to. The gold protects the nickel throughout storage and in addition offers the low contact resistance required for the thin gold deposits. ENIG is now arguably essentially the most used end within the PCB trade due the growth and implementation of the RoHs regulation.

Another coating consideration is fast diffusion of coating metal into tin solder. Tin varieties intermetallics such as Cu6Sn5 and Ag3Cu that dissolve into the Tin liquidus or solidus (at 50 °C), stripping surface coating or leaving voids. Each trace consists of a flat, slender a part of the copper foil that continues to be after etching. Its resistance, decided by its width, thickness, and length, have to be sufficiently low for the present the conductor will carry.

Surface-mount know-how emerged within the Nineteen Sixties, gained momentum in the early Nineteen Eighties and have become widely used by the mid-Nineteen Nineties. Components had been mechanically redesigned to have small metallic tabs or end caps that might be soldered instantly onto the PCB floor, as a substitute of wire leads to move through holes. Components grew to become a lot smaller and element placement on both sides of the board grew to become more common than with by way of-hole mounting, permitting much smaller PCB assemblies with a lot higher circuit densities.

Because of the numerous actions via hole processing calls for, damage on the board can easily be made and can injury the protective layer. Also, a PCB with OSP ending is harder to solder after the reflow process. The order of the layers over the substrate corresponds to the name of this floor finish. The palladium prevents the nickel from passing by way of to the gold layer on prime.

The course of consists of immersing circuit boards in a molten pot of a tin/lead alloy after which removing the surplus solder by using 'air knives', which blow sizzling air across the surface of the board. Naturally, it’s not the job of electronics designers like you to rigorously inspect the thickness of film when receiving circuit boards. During board manufacturing, thickness of floor end has to be rigorously managed before they go away workshop. For example, PCB fabrication conforms to guidelines and regulations of Standard IPC 2.

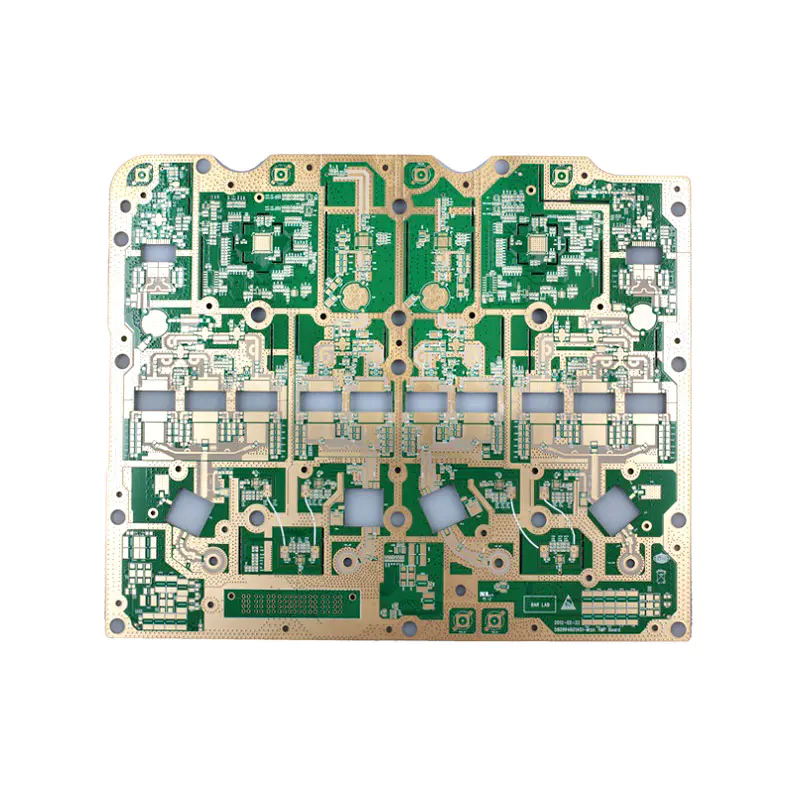

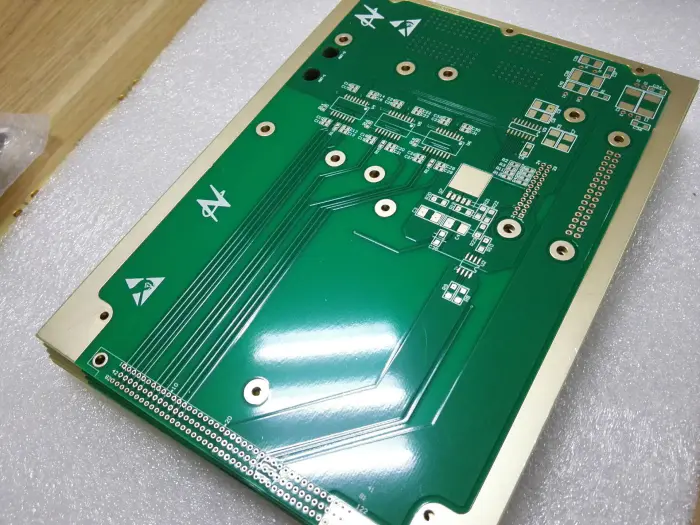

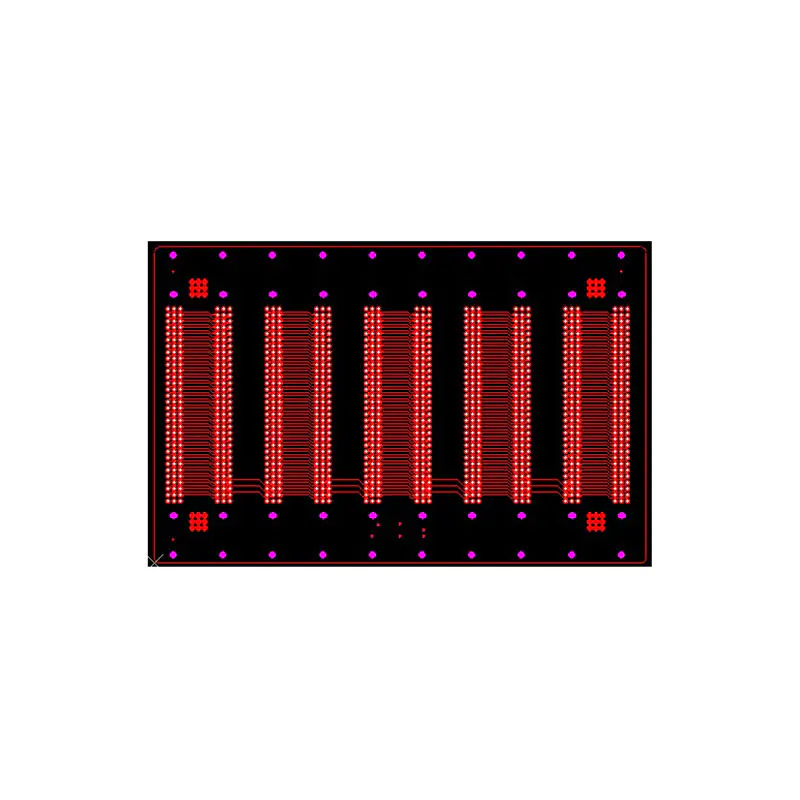

In a multi-layer board one whole layer may be mostly solid copper to act as a floor airplane for shielding and energy return. For microwave circuits, transmission lines could be laid out in a planar form such as stripline or microstrip with fastidiously managed dimensions to assure a consistent impedance. High density interconnects (HDI) PCBs have tracks and/or vias with a width or diameter of under 152 micrometers.

Plus, more than 10 years’ expertise and instances’ experiments enable engineers there to acquire optimum solution concentration and shifting velocity of conveyor belt, which further leads to perfect OSP thickness. HENGKAITUO have been offering a high quality & price efficient PCB meeting one cease answer to customer since 2004. ball-grid-array (BGA) housings or tiny floor-mount-know-how (SMT) packages.

A plated end can present that smooth mounting surface for miniature parts, and it could ship long-time period protection towards copper deterioration. Some finishes additionally shield the plated by way of holes (PTHs) that serve as the electrical connections between totally different circuit layers in multilayer PCBs. A printed circuit board must have a surface end or coating to protect the copper circuitry from oxidation. The floor finish can also be used to provide a solderable surface when assembling to promote reliable solder joints for lengthy-time period performance.