Corrosionpedia

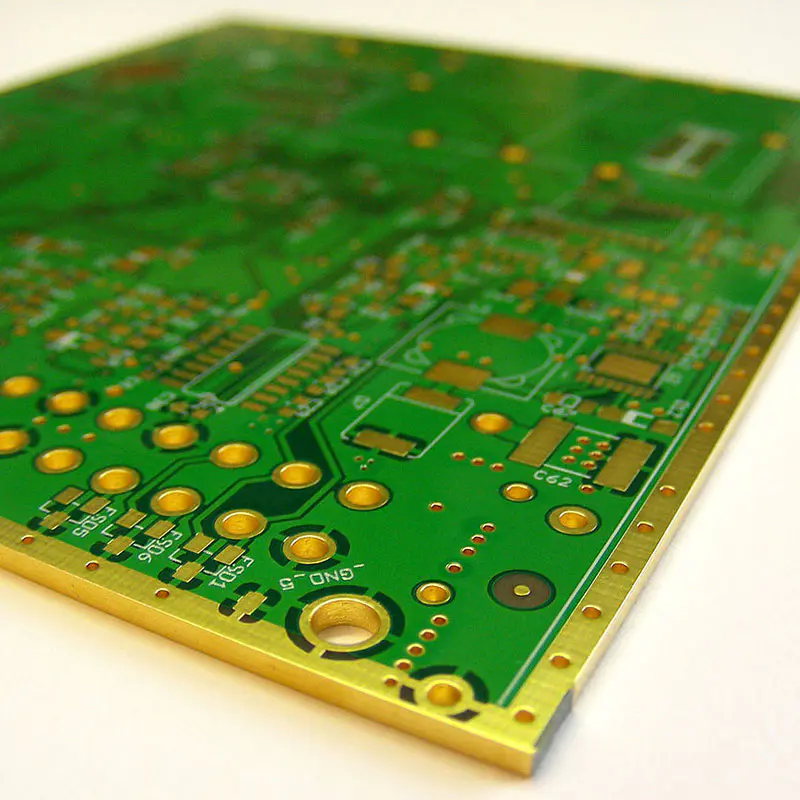

The creep of the corrosion merchandise on the surfaces of ENIG-plated layers, tin-primarily based solders and adjoining soldermasked areas was additionally found to be answerable for creating quick circuits on the outer layers of the miniaturized PCB. First is to protect the exposed copper circuitry and second is to make sure solderability. The difference in material used will have an effect on the price, shelf life, reliability and assembly processing.

Comparing each sorts and all available options can shortly reveal the relative benefits or drawbacks. Typically, the decisive components in terms of deciding on essentially the most appropriate end is the tip software, the assembly process and the design of the PCB itself. Below yow will discover a brief abstract of the commonest finishes, however for further or extra detailed info, please contact NCAB Group and we shall be more than pleased to reply any of your questions. With the rapid development of society, environment safety is our focus, which forces PCB trade to reduce the air pollution.

In order to chop the cost and shield environment, the application of OSP will be the mainstream. Here you may find insights into PCB design, tech tendencies, meeting points, and trending topics in the general news media as they relate to printed circuit board expertise. As a part of any improvement process it is normally advisable to make a prototype before committing to full production.

OSP is to develop a layer of organic skin film on the clean bare copper floor by chemical technique. The movie has oxidation resistance, warmth shock resistance and moisture resistance, which is used to protect the copper floor of circuit board from oxidation or vulcanization in normal surroundings.

It provides a constantly flat floor roughly micro inches in thickness. However, finished PCBs have a limited shelf life and should be used within three-6 months. Hard gold finishing is used when mechanical contact stress is opposed to the PCB.

For example, PCB edge finger contacts or take a look at sockets with strain pins. To stop damaging to the copper itself the surface is protected with 10 µm gold (Au) upon a nickel barrier various from 10 to 100 µm. Its primary drawback is its poor solderability because of the hardened golden floor. According to IPC rules, a gold thickness of 0.forty five µm Au is the restrict for proper soldering.

PTH filling throughout wave soldering can be tough if no-clean flux is used. Reflow temperatures start to degrade the OSP coating, particularly if the PCB experiences two reflow cycles. If the OSP coating degrades, oxidation will type on the copper floor. If the oxidation is fairly thick and widespread, the no-clean wave soldering flux won't be able to remove it, affecting solderability and gap filling. Using nitrogen during reflow soldering or more energetic wave soldering fluxes will help solve the outlet filling problem.

Some typical surface finishes like HASL are the primary reason for pollution. Before 2005, it's the century of lead because virtually all the PCBs are produced with lead that is a harmful substance and can impression on water and air. Since 2006, government and a few establishments have asked manufacturers to switch the HASL with HASL lead free.