China Osp Pcb, China Osp Pcb Manufacturers And

The Gold readily dissolves into solder and doesn't tarnish or oxidize. While the Nickel strengthens the PTH, increases thermal cycle life, and acts as a barrier that stops Copper dissolution throughout wave solder and rework. HASL Finish is the predominant ‘leaded’ floor finish used in the trade. All of those will influence your choice of the optimum PCB Surface Finish on your project. Microerosion The objective of Micro-etching is to type rough copper floor and to facilitate movie formation.

Solder paste printing I artwork should be mastered nicely as a result of the plate with poor printing can't be cleaned with IPA, which can harm the OSP layer. The OSP is manufactured from a water-primarily based compound that bonds to copper selectively. And, as a result of this end is water-primarily based and organic, it’s one of the greenest supplies obtainable. However, its organic construction offers it a short shelf life-usually about 9 months with special storage methods.

Below, we’ve listed a number of of the best and generally used finishes that you could choose from. Below, we clarify precisely what a floor finish is and other related information so you higher perceive why this half is so important to a PCB’s performance. If you still need assistance selecting the best PCB Surface Finish for your project, give us a call and certainly one of our expertise technical gross sales staff members will information you in the proper direction. Immersion Silver is a good surface end if one is confident that the product will not be uncovered to sulfur during delivery or use of the product. This floor finish acquired a boost in popularity after the Underwriters Laboratory performed temperature/humidity/bias testing with favorable outcomes, by which no electromechanical migration happened.

The thickness of Micro-etching immediately affects the movie forming fee, so it is rather necessary to kind a stable film thickness and keep the steadiness of Micro-etching thickness. Generally, it is acceptable to regulate the thickness of Micro-etching at 1.0-1.5um. Before each shift production, the micro-corrosion rate could be measured, and the micro-corrosion time may be determined in accordance with the micro-corrosion fee. It's actually a query that cannot be answered until a user works with a supplier to confirm the fabric and the process used. All finishes when it comes to wetting are changed when you reflow them one and a second time and the hold time does have an effect.

In explicit, plasma or activated gases could possibly be used to wash the solder pad immediately before and during the soldering step. The soldering operation of SMT patch solder on the PCB surface of the PCB ought to be accomplished inside 1 hour after the completion of the improper cleansing of PCB. The unused overrunning empty plates, the moist empty plates, and the empty plates cleaned by poor batch printing shall be returned to the PCB manufacturer for OSP heavy processing before use. However, the same plate cannot be used for more than 3 times, in any other case it needs to be scrapped.

Do not keep within the furnace as soon as possible after printing (not than 1 hour), as the flux in the solder paste is highly corrosive to OSP movies. About 63% of these are other pcb & pcba, 14% are pcba, and 5% are multilayer pcb.

A-TECH CIRCUITS Co., Ltd. has created a professional team which contained with a numbers of engineers and technology experts.

Our vision serves as the framework for our pcb supplier and guides every aspect of our business by describing what we need to accomplish in order to continue achieving sustainable, quality growth.

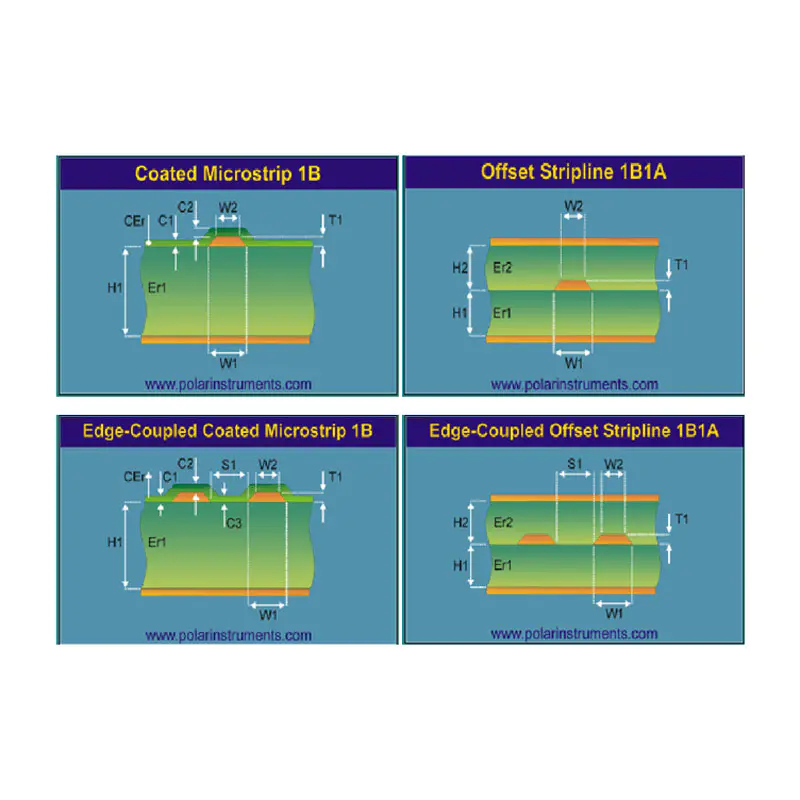

have three basic components.