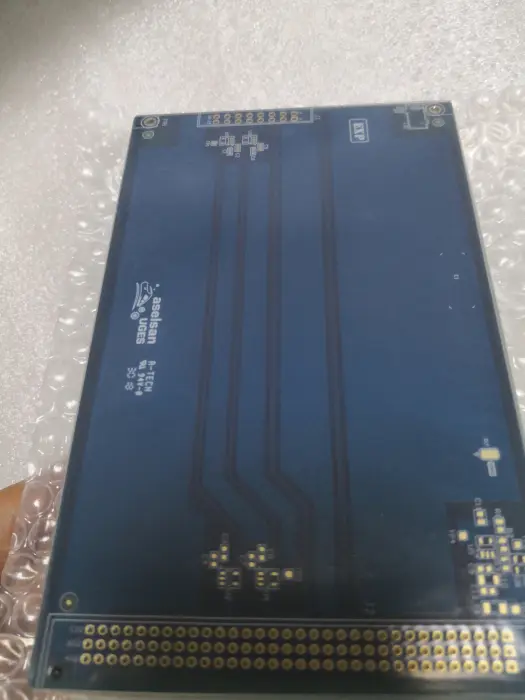

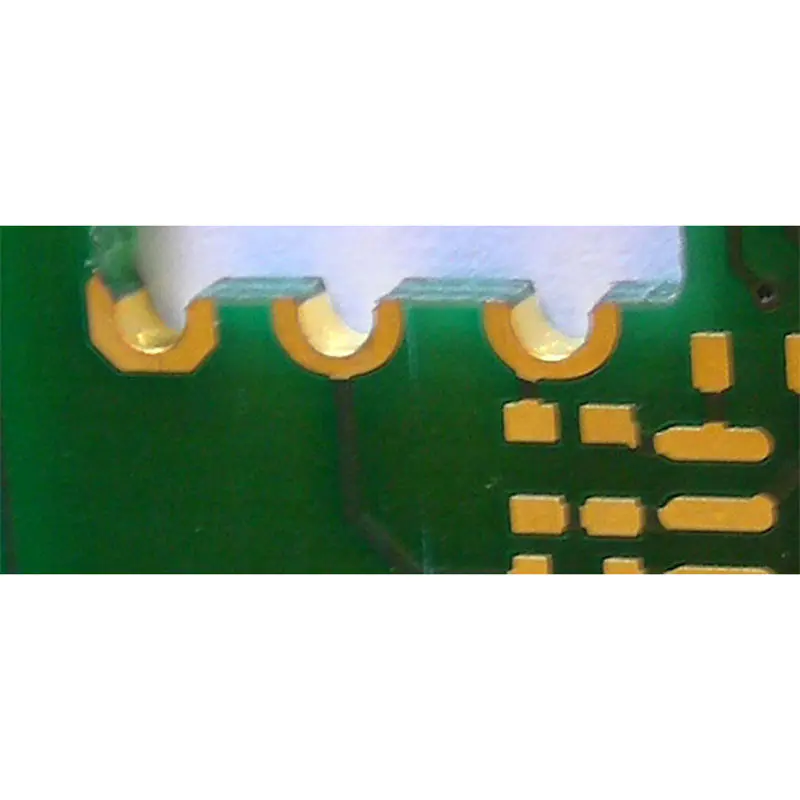

Castellated Mounting Holes

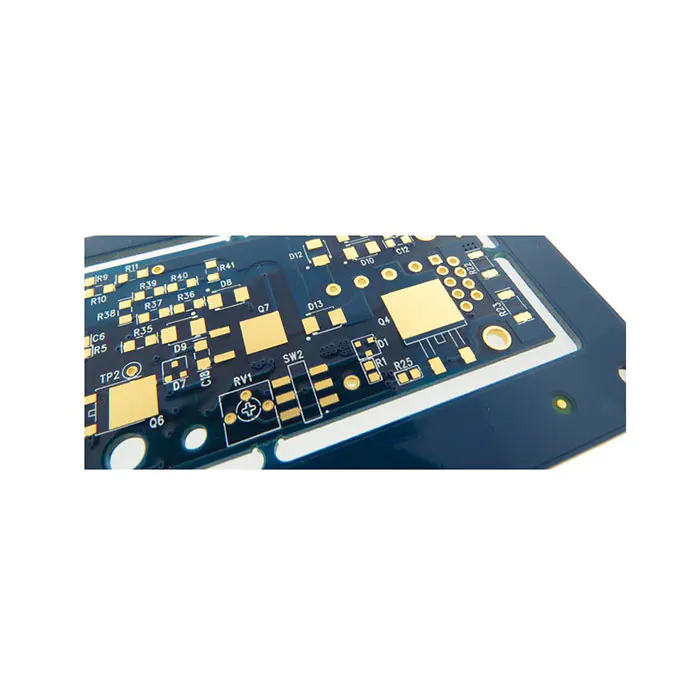

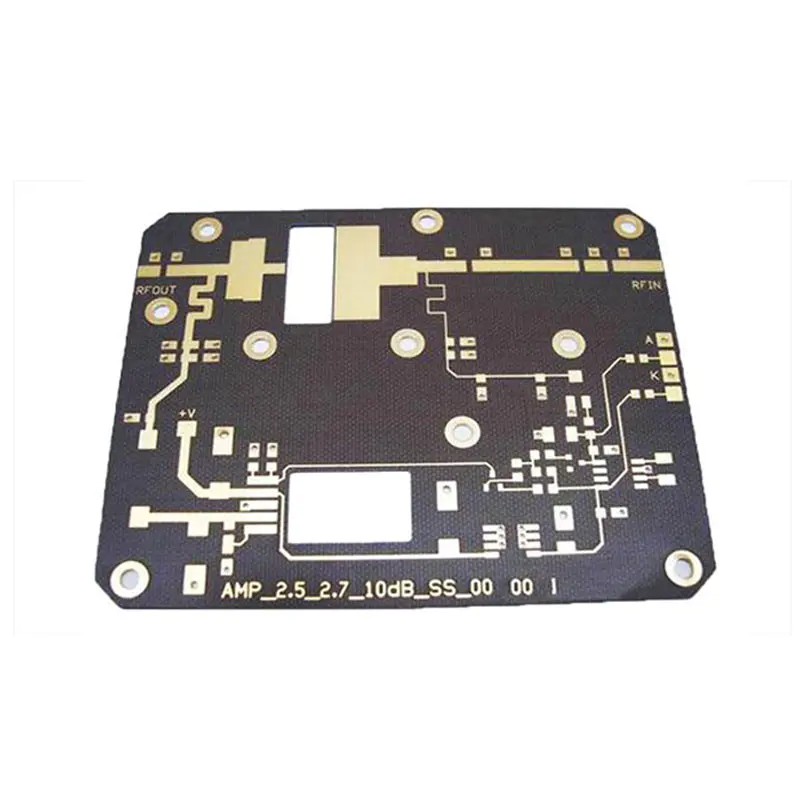

Copper plating serves two functions, it will increase the copper thickness of the surface pads and conductors as well as offering a sturdy copper connection from layer to layer via the plated through-holes. Early ENIG processes had poor adhesion to copper and lower solderabiliy than HASL. In addition, a non-conductive layer containing nickel and phosphorus, generally known as 'black pad', may kind over the coating as a result of sulfur-containing compounds from the solder masks leaching into the plating tub. In short, the lowest conductor losses, with microstrip and GCPW, are achieved utilizing naked copper conductors.

All the important considerations about meeting must be taken into floor finish choice in order to make sure the high quality and efficiency of finish products. Comparing these types of floor finishes, generally talking, in terms of COST, ImAg and OSP are essentially the most cheap while ENIG is the most expensive. In phrases of CORROSION RESISTANCE, HASL and ImSn have the best corrosion resistance capability whereas ImAg has the worst.

It should not be used to exchange electrolytic gold plating since its adhesion and thickness is limited in comparison with a standard electroplated gold. There are typically two kinds of applied sciences used through the PCB Assembly process, by way of gap (THT) and surface mount (SMT). There is another know-how that is becoming common these days that is used when there's a must mount a single module board on high of another PCB, this technology is called board-to-board soldering.

Castellated holes (also referred to as castellations) are becoming more widespread in printed circuit board fabrication because the demand for circuit board modules will increase. Plating on a PCB refers back to the electrochemical course of by which a metal is deposited onto the floor of the circuit board, and contained in the plated via-holes.

But it is not practical to fabricate dependable PCBs with naked copper conductors, and plated PCB finishes present much-wanted long-term safety. As was found from measurements and simulations, all PCB plated finishes are not the identical, with some suffering less loss than others. For measurements on excessive-frequency PCB materials by way of one hundred ten GHz, circuits with bare copper conductors have the least conductor loss, adopted by circuits with immersion tin, ENIPIG finish, after which ENIG finish. Surface end choice on PCBs is the most important step for PCB fabrication since it instantly influences process yields, rework numbers, area failure price, test functionality, scrap rate and cost.