Company Advantages1. Conventional and special processing techniques are used in A-TECH press fit pins pcb production. They include welding, cutting, and honing. Thanks to the up-to-date vacuum DES line, it is manufactured with fine traces and high density

2. A-TECH CIRCUITS Co., Ltd. has perfect QC system and after-sales system to ensure quality and good user experience. The product has the performance of great stability

3. It is one of the most environmentally friendly packaging & printing product one will find. It is recyclable and the recycling process is energy efficient, so there is no worry about losing energy. It can reduce the electrical signal loss and provides the highest efficiency

4. The product is structurally sound. Its robust industrial strength frame makes it less susceptible to many factors such as shock and vibration. It is offered with low dielectric loss

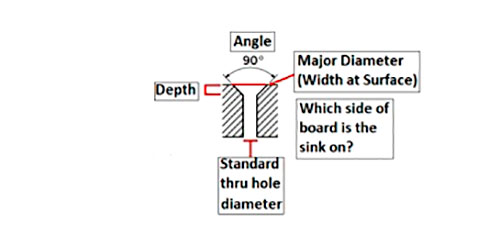

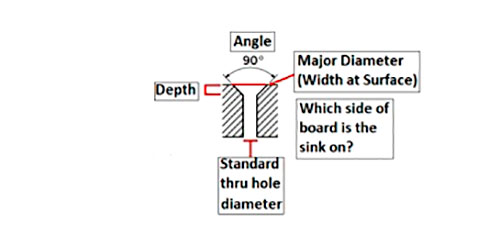

The countersink is a kind of conical hole which drilled by special drill bits, it allows the tapered head of a screw to be inserted and screwed down in the hole to sit flush with the surface of the circuit board.

In order to ensure correct manufacturing for countersink design, PCB manufacturers require the details of the hole diameter or other specifications, the detailed information as below is needed:

● Countersink is drilled on top or bottom side?

● Countersink is copper plated or non-plated?

● The angle of countersink

● The finished diameter of countersink at the surface

● The depth of countersink

● The finished diameter of the shaft of the countersink

Drill bit with different angles are the key tools to make countersink, the angles with 82 degree and 90 degree are usually used in many kinds of design, but other angles like 60 degree, 100 degree, 110 degree, 120 degree and so on are also possible based on demands.

A-TECH is capable of building different types of countersink with different diameters and angles, and no matter copper plated or non-plated, welcome to send inquiry if you have related demands.

Company Features1. A-TECH CIRCUITS Co., Ltd. has evolved into a manufacturing pioneer in this field. We have gained a high reputation of manufacturing quality via in pad technology in the domestic market. A-TECH CIRCUITS Co., Ltd. is known for its technological achievements.

2. A-TECH pays a lot of attention to the quality of

via in pad pcb .

3. A-TECH CIRCUITS Co., Ltd. has established a more complete quality assurance system and product testing standards. We work systematically to ensure that our suppliers share our values and adhere to our standards of business ethics, health & safety, environmental, and social responsibility as specified in our Business Partner Code of Conduct.