Company Advantages1. A-TECH press fit pins pcb is made by adopting the world's newest production technology. The product is certified under UL(E357001) and RoHS

2. Since the establishment, A-TECH CIRCUITS Co., Ltd. has relied on the development vision of press fit pins pcb. Its solder mask can be offered with green, blue, white, black, yellow, and red colors

3. The product has the advantage of high accuracy. The check function has been built-in the software to ensure that the information entered is accurate and correct. It has passed AOI which ensures there will be no errors or welding defects

4. This product is fire resistance. A certain amount of flame retardant is added to its materials during the preliminary production stage. It can reduce the electrical signal loss and provides the highest efficiency

5. The product has remarkable quality, which has been highly evaluated and proved by the third-party testing organizations in terms of material and workmanship referring to the gifts and crafts. It totally conforms to the UL Flame Rating of 94V-0

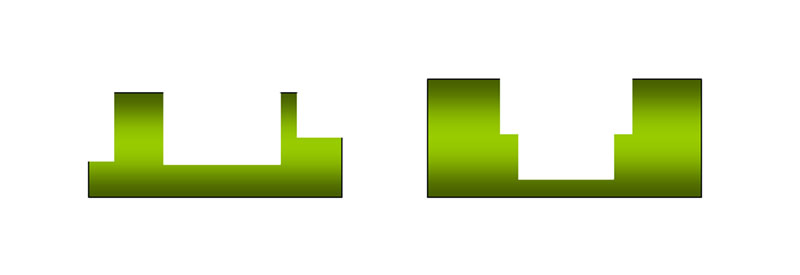

Depth control routing(milling) is also known as Z-axis milling or level milling, it refers to partial routing in printed circuit board manufacturing with a variable level elevation at the PCB edge or within PCB.

Control depth routing technology supports a high end market with the need for accuracy, miniaturization, process stability and the need for productivity, and depth routing option allows for very complex designs, bended boards and structures to be processed with fine precision.

Depth control routing technology have great advantages in PCB assembly as the special shape of depth routing.

● It can avoid cold soldering as siphonic effect use NPTH step stair slot

● Use the step stair in middle of PCB apply in special module application, and degrade the height of PCB assembly, achieve refinement and miniaturization

● Use the step stair of PCB edge make card slot is favor for PCB fixed and installation

● Use Special size NPTH step stair as resonant cavity of microwave signal, degrade signal loss and other special function.

A-TECH has manufacturing capability to build various types of depth routing with different size and depth, no matter on the PCB edge or within the PCB, and the precision tolerance can be controlled as +/-0.1mm(4mil).

Company Features1. A-TECH CIRCUITS Co., Ltd. is committed to the production of

impedance pcb since the day of its establishment. We offer many types of product certifications which result in easier access to global markets. With many consumers, retailers, and distributors looking to differentiate their products, our range of certifications are ideal to re-assure your customers that products have been independently assessed for compliance.

2. Our factory has been ISO 9001 certified. The results of following the standards in ISO 9001 system have brought us many benefits, such as profitability, increased productivity, as well as saved costs.

3. The factory operates on a strict quality management system. Right from inspection & testing of raw material to final pre-dispatch of end products, this system can ensure zero-defect product quality. Our company bears social responsibilities. We stick to daily shutdown SOPs for copiers, PC monitors, and other office machines when not in use.