Depth control routing(milling) is also known as Z-axis milling or level milling, it refers to partial routing in printed circuit board manufacturing with a variable level elevation at the PCB edge or within PCB.

Control depth routing technology supports a high end market with the need for accuracy, miniaturization, process stability and the need for productivity, and depth routing option allows for very complex designs, bended boards and structures to be processed with fine precision.

Depth control routing technology have great advantages in PCB assembly as the special shape of depth routing.

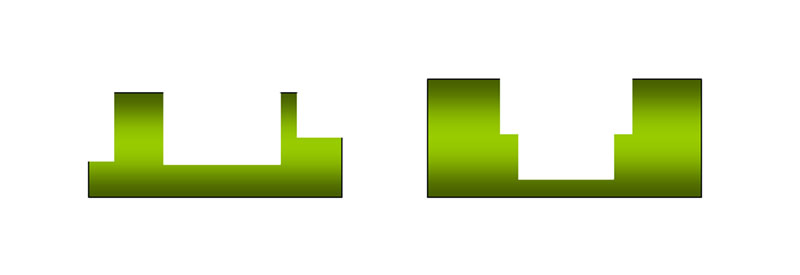

● It can avoid cold soldering as siphonic effect use NPTH step stair slot

● Use the step stair in middle of PCB apply in special module application, and degrade the height of PCB assembly, achieve refinement and miniaturization

● Use the step stair of PCB edge make card slot is favor for PCB fixed and installation

● Use Special size NPTH step stair as resonant cavity of microwave signal, degrade signal loss and other special function.

A-TECH has manufacturing capability to build various types of depth routing with different size and depth, no matter on the PCB edge or within the PCB, and the precision tolerance can be controlled as +/-0.1mm(4mil).

Copyright © 2025 A-TECH CIRCUITS Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.