Advantages And Disadvantages Of Osp Surface Treatment

Laser depaneling reduces stress on the fragile circuits, bettering the yield of defect-free items. Moisture absorption occurs when the fabric is exposed to high humidity or water.

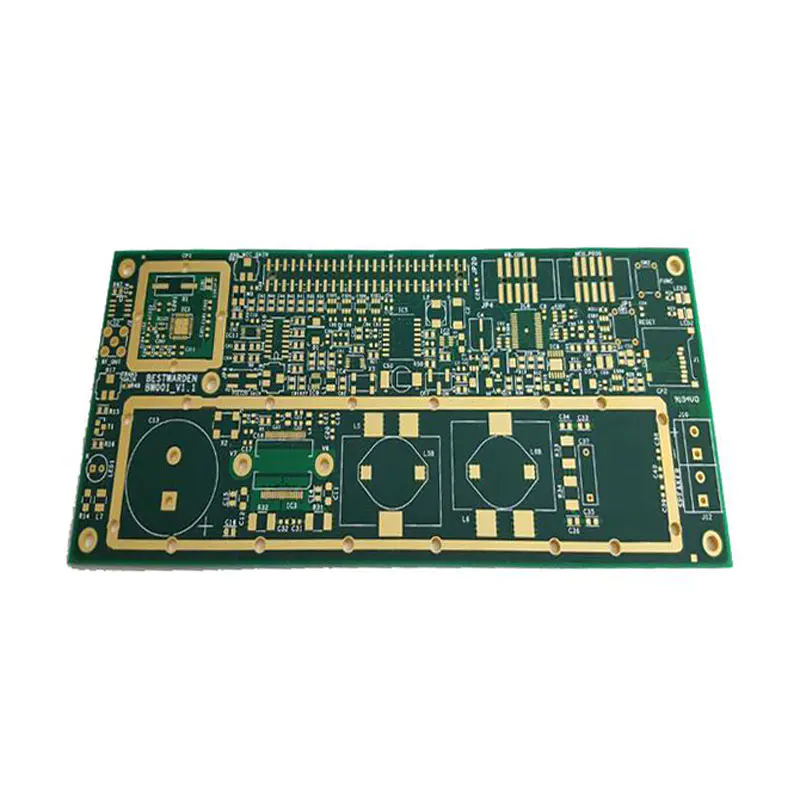

PCBs can also be made manually in small portions, with decreased advantages. Throughout the years, PCBs have evolved from the straightforward single-layer PCBs utilized in electronics such as calculators to extra advanced techniques, corresponding to a high-frequency Teflon design. PCBs have discovered their way into nearly each business on the planet, from simple electronics like lighting options all the best way as much as more advanced industries like medical or aerospace technology. The aluminum backing is lined with thermally insulating materials that is designed to have a low thermal resistance, meaning much less warmth is transferred from the insulating materials to the backing.

Automatic optical inspection (AOI) machines examine a picture of the board with the digital image generated from the unique design data. Automated Optical Shaping (AOS) machines can then add lacking copper or remove excess copper using a laser, reducing the number of PCBs that have to be discarded. Subtractive strategies remove copper from a completely copper-coated board to depart only the desired copper pattern.

Relative dielectric constant of water is about 73, compared to about four for widespread circuit board materials. Absorbed moisture can even vaporize on heating, as during soldering, and trigger cracking and delamination, the identical impact answerable for 'popcorning' damage on moist packaging of digital elements. Careful baking of the substrates may be required to dry them prior to soldering. The European Union bans the use of lead (among different heavy metals) in consumer gadgets, a piece of legislature referred to as the RoHS, for Restriction of Hazardous Substances, directive.

In additive strategies the pattern is electroplated onto a naked substrate utilizing a complex process. The advantage of the additive technique is that much less materials is needed and less waste is produced. In the complete additive course of the bare laminate is roofed with a photosensitive movie which is imaged (exposed to gentle via a masks and then developed which removes the unexposed movie).

Alternatives to PCBs embody wire wrap and level-to-level building, each as soon as in style however now hardly ever used. PCBs require additional design effort to put out the circuit, but manufacturing and meeting may be automated. Electronic laptop-aided design software program is on the market to do much of the work of format. Mass-producing circuits with PCBs is cheaper and sooner than with different wiring methods, as components are mounted and wired in one operation. Large numbers of PCBs can be fabricated on the identical time, and the format only has to be carried out as soon as.

For small or medium volume manufacturing flying probe testers are used the place check probes are moved over the board by an XY drive to make contact with the copper lands. There is no want for a fixture and hence the fixed costs are a lot decrease. The CAM system instructs the electrical tester to apply a voltage to every contact level as required and to verify that this voltage seems on the suitable contact factors and only on these. It contains the component designators, swap settings, test factors and other indications useful in assembling, testing, servicing, and generally utilizing the circuit board. The inner layers are given an entire machine inspection before lamination as a result of errors can't be corrected afterwards.

Boards with no elements put in are normally naked-board tested for 'shorts' and 'opens'. A brief is a connection between two points that shouldn't be related. An open is a missing connection between points that should be related. For high-volume manufacturing, a fixture or a inflexible needle adapter makes contact with copper lands on the board. The fixture or adapter is a major fastened value and this methodology is just economical for prime-volume or high-value production.

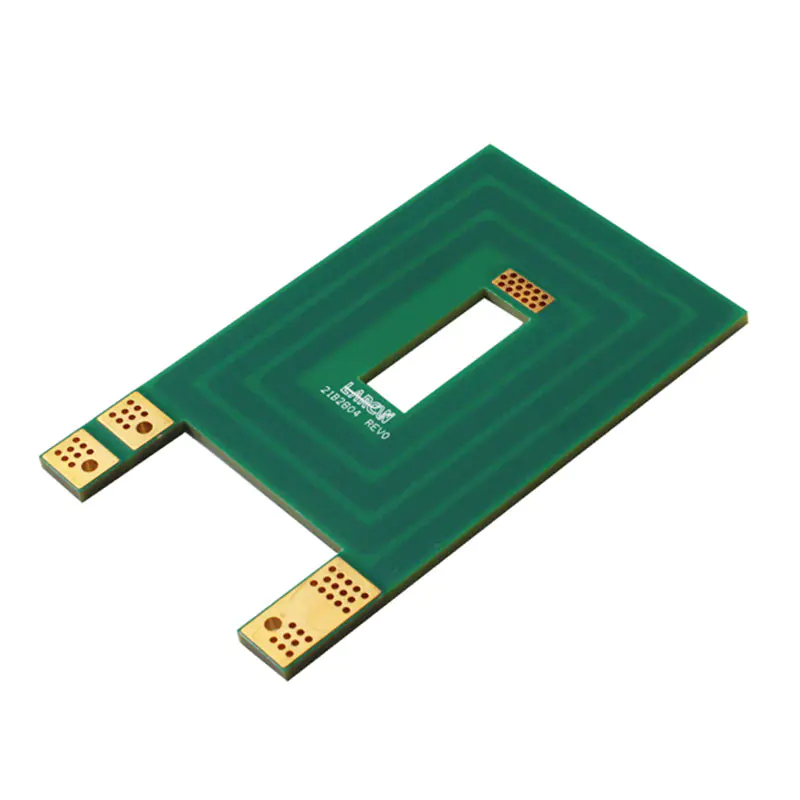

The uncovered areas are sensitized in a chemical bath, normally containing palladium and similar to that used for via gap plating which makes the exposed area able to bonding metallic ions. The panel is ultimately broken into individual PCBs alongside perforations or grooves in the panel via milling or chopping. For milled panels a typical distance between the individual boards is 2 to three mm. Today depaneling is usually done by lasers which cut the board with no contact.

Both the resin and the reinforcement may take in water; water also could also be soaked by capillary forces via voids in the materials and alongside the reinforcement. Epoxies of the FR-4 materials usually are not too vulnerable, with absorption of only 0.15%. Polyimides and cyanate esters, on the opposite aspect, undergo from high water absorption. Absorbed water can result in vital degradation of key parameters; it impairs monitoring resistance, breakdown voltage, and dielectric parameters.