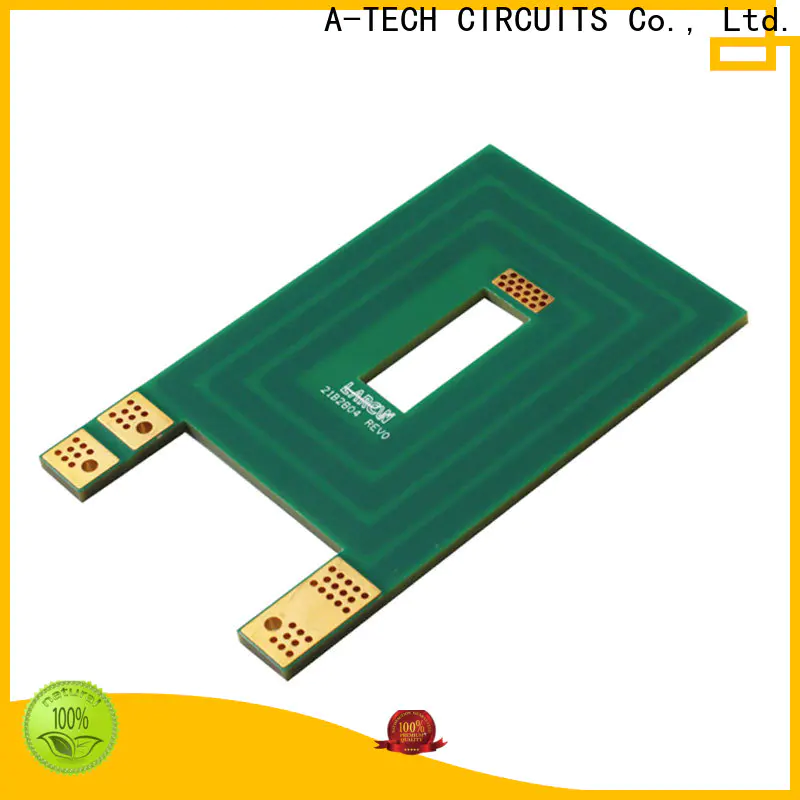

Thick copper PCB or called Heavy copper PCB, it refers to the printed circuit boards with copper thickness more than 3oz(ounce), they’re usually used for various electronic devices like central power system and power electronic devices which need high power or current through.

The applications of thick copper PCBs

● UPS systems

● Protection relays

● High power rectifiers

● Power grid switching systems

● Energy storage and power grid back up

● High power distribution

● Heat dissipation

● Planar transformers

● Power convertors

The advantages of thick copper PCB

● Better current carrying capacity

● Increased endurance to thermal strains

● Added copper plating in the heat vias

● Elimination of complex wired buss configurations

● Increased mechanical strength at connector sites

● Optimized use of exotic high temperature materials with lower probability of circuit failure

A-TECH have manufactured heavy copper PCBs more than ten years with very rich experience. Currently we’re capable of manufacturing thick copper PCB up to 12oz with our limit production capability.

Copyright © 2025 A-TECH CIRCUITS Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.