A-TECH Pcb Fabrication

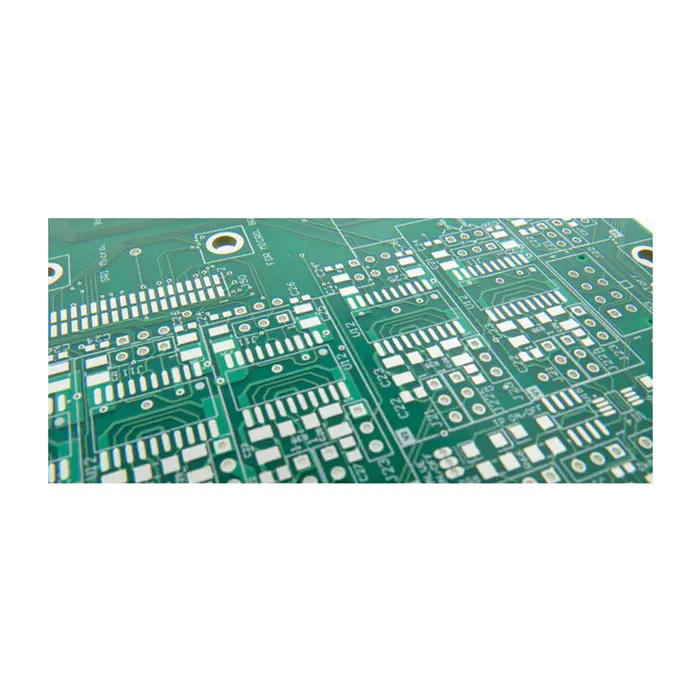

The perform of “Clean” is to clean off the natural contaminants such as oil, finger prints, oxidation movie etc. so as to get copper foil surface keep clean and bright. On the opposite hand, cleaning effect is suggested to be checked as typically as possible and as soon as the impact doesn’t attain the usual, cleansing answer ought to be changed in time. In terms of film thickness, movie made by way of benzotriazoles is skinny while that made via imidazoles is relatively thick. Elecrow PCBA is a professional PCBA solution service supplier specialized in one-stop service in your PCB fabrication, parts sourcing, PCB assembly, Function testing, Sub-Assembly& Kitting Service, save your time and value.

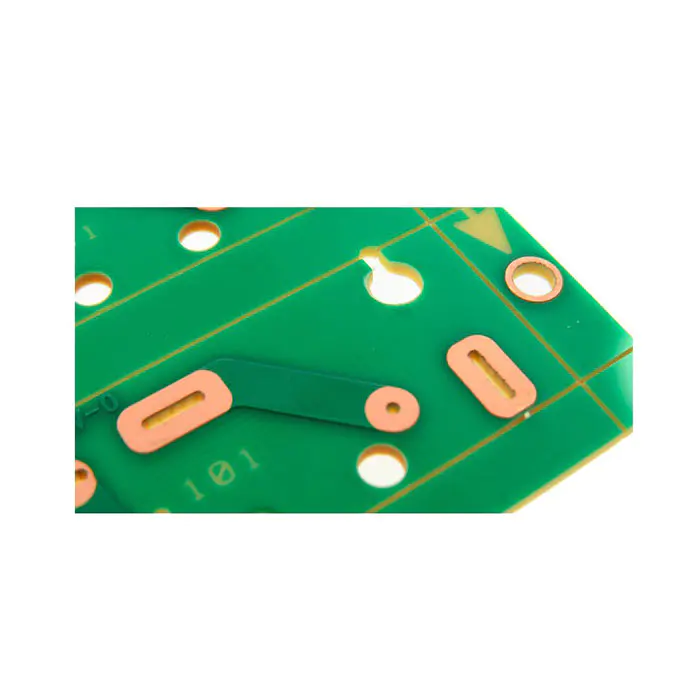

The floor isn't fully stage, so this can cause a difficulty with small components. “Hot Air Solder Leveling” is the least costly type of PCB surface finish. There are assorted options for PCB floor finishes and each has advantages and downsides.

In terms of the advantages of ImSn, it provides an especially planar end on the copper pads, making it very suitable for SMT purposes. Besides, ImSn offers a floor that's easily detectable by common Automated Optical Inspection methods.

The different surface finishes must perform by way of a number of thermal cycles with less energetic pastes and fluxes. Based on the introduction of each sort of surface end above, some attributes are an important components as the selection normal. The below desk shows the attributes each sort of surface end HAS and DOESN NOT HAVE. Based on particular requirements and options of PCB products, you possibly can comply with this desk to select the proper floor end choice. ImSn is mostly the identical as ImAg besides that tin is used in ImSn while silver is utilized in ImAg.

Furthermore, indicators of non wetting of the OSP on the solder facet are nearly solely witnessed on the boards aged with a peak of 240°C. The water based selective soldering flux SelectIF 2040 was used for all boards. The reflow profile of 240°C will simulate the ageing of the OSP coating when submitted to a double sided reflow process with a regular lead-free solder paste. The reflow profile of 200°C will simulate the ageing of the OSP coating when submitted to a double sided reflow process with an LMPA™-Q solder paste.

Further, regulations corresponding to RoHS and WEEE have changed business requirements. 2.The defect of the OSP process is that the ensuing protective movies are extremely skinny and straightforward to scratch (or abrade) and should be rigorously operated and operational amplifiers. At the identical time, after many occasions of high temperature welding course of, the OSP film (the OSP film on the non welded connecting plate) will change color or crack, which is able to have an effect on solderability and reliability. one-cease supply for printed circuit board fabrication and PCB prototyping. These are the PCB floor finishes we've out there on your PCB order.

Fluxes are additionally used in foundries for eradicating impurities from molten nonferrous metals corresponding to aluminium, or for adding fascinating trace parts corresponding to titanium. For Circumstance#1, within the means of soldering, flux is capable of helping eliminating oxidations in order that soldering performance won’t be influenced. On the contrary, Circumstance#2 takes place as a result of OSP integrity has been destroyed in order that flux can’t remove oxidations, which is able to greatly decrease the soldering performance.

Palladium has the next hardness stage than gold, which results in the advance of solder reliability, wire bonding capability and antifriction. However, once the PCB is faraway from its packaging, it will need to undergo solder reflow inside a day. The board is dipped in molten solder after which leveled off with a scorching air knife. If you might be utilizing via-gap or larger SMT components, HASL can work well; in case your board may have nice pitch SMT parts or smaller than 0402 elements, it isn't best.

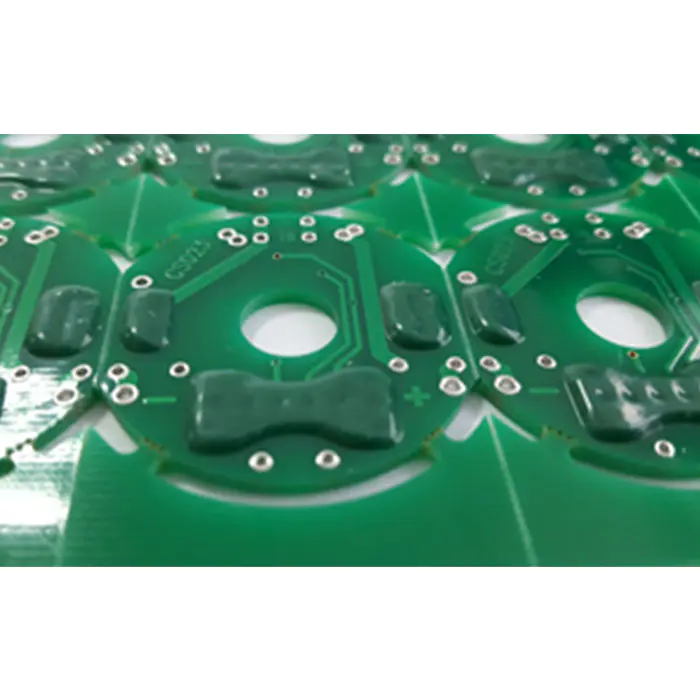

The ever rising packaging density on PCB boards and the changeover to lead-free alloys have played a major position in the evolution and choice of PCB board finishes. ENEPIG know-how developed based mostly on ENIG technology by including a palladium layer to improve performance. The palladium layer totally covers the nickel layer to keep away from degeneration of nickel, commonly referred to as black pad.