Rogers PCB refers to the printed circuit boards fabricated with the raw material from Rogers Corporation. Rogers Corporation is the world’s technology leaders in innovative solutions for high-frequency printed circuit materials.

Traditional FR4 PCB material provides the base standard for PCB substrates, delivering a widely effective balance between cost, manufacturability, electrical properties, durability and performance, but when advanced electrical properties, reliability, efficiency and performance are critical to your designs, Rogers PCB is one of the ideal solution due to its advantages as following.

● Lower Dielectric loss

● Low electrical signal loss

● Wide range of DK(dielectric constant) values(2.55-10.2)

● Low cost circuit fabrication

● Low outgassing for space applications

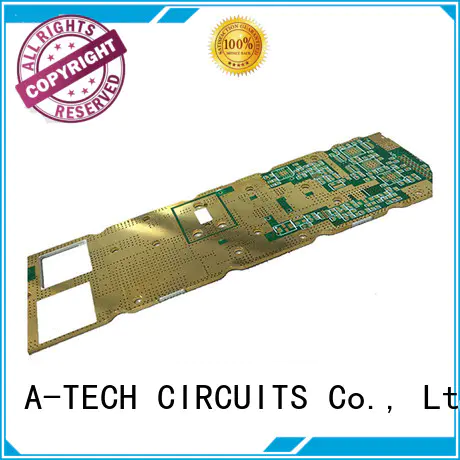

A-TECH CIRCUITS is a reliable Rogers PCB manufacturer whom manufactured a large number of Rogers PCB with different Rogers material for worldwide customers. Since we have strategic cooperation with Rogers corporation on material sourcing, our price of Rogers PCB can be quite competitive in the worldwide market with high quality.

The Rogers material we have used for manufacturing printed circuit boards include RO3000 Series, RO4000 Series, RO4400 Series, RO4500 Series and RT / duroid Series. RO4000 Series with Rogers 4350B and 4003C are most popular and used most widely.

Rogers 4350 PCB & Rogers 4003 PCB

Rogers 4350 and Rogers 4003 offer superior high frequency performance and low cost circuit fabrication resulting in a low loss material which can be fabricated using standard epoxy/glass(FR-4) processes. These material possesses the proterties needed by designers of RF microwave circuits and matching newworks and controlled impedance transmission lines, they offer a range of dielectric constants(2.55 – 6.15), are available with UL 94V-0 flame retardant versions.

The benefits of Rogers 4350 PCB & 4003 PCB

● Low Z-axis CTE for reliable plated through-hole quality

● Robust lead-free solder processing compatibility

● High thermal conductivity for improved thermal management over traditional PTFE materials

● Optimized cost and RF/Microwave performance

● Compatible with FR4 fabrication including multilayer PCB constructions.

Copyright © 2025 A-TECH CIRCUITS Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.