Company Advantages1. A-TECH

impedance pcb is designed by our designers who carefully check the suitability of the chosen solution and give valuable advice concerning the selection of materials and finishes.

2. It can continually regulate the skin's microclimate. As the skin gets hot, the heat is absorbed, and as it cools, that heat is released.

3. Structural construction can be completed by simply emplacing the same kinds of this product. It is already designed to interlock for ease of mobility during transportation.

4. A-TECH has the most advanced machine to test the quality of

edge plating pcb before its loading.

5. The reliable quality of the product ensures stable development prospects.

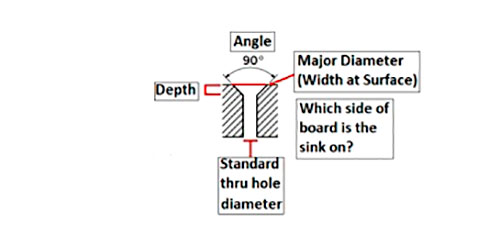

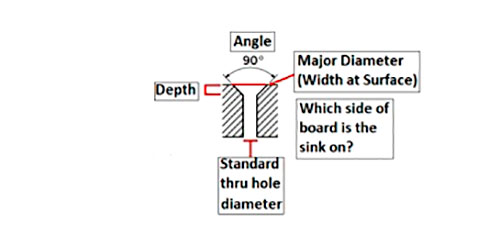

The countersink is a kind of conical hole which drilled by special drill bits, it allows the tapered head of a screw to be inserted and screwed down in the hole to sit flush with the surface of the circuit board.

In order to ensure correct manufacturing for countersink design, PCB manufacturers require the details of the hole diameter or other specifications, the detailed information as below is needed:

● Countersink is drilled on top or bottom side?

● Countersink is copper plated or non-plated?

● The angle of countersink

● The finished diameter of countersink at the surface

● The depth of countersink

● The finished diameter of the shaft of the countersink

Drill bit with different angles are the key tools to make countersink, the angles with 82 degree and 90 degree are usually used in many kinds of design, but other angles like 60 degree, 100 degree, 110 degree, 120 degree and so on are also possible based on demands.

A-TECH is capable of building different types of countersink with different diameters and angles, and no matter copper plated or non-plated, welcome to send inquiry if you have related demands.

Company Features1. A-TECH CIRCUITS Co., Ltd. is a well-known supplier of edge plating pcb . We have the experience and expertise to fulfill customers unmet needs.

2. The standard nature of these processes permits us to fabricate impedance pcb .

3. As long as A-TECH CIRCUITS Co., Ltd. sticks to the scientific principles of circuit board assembly, we will be able to ensure that we will seize the forefront in impedance control pcb industry. Check it! A-TECH CIRCUITS Co., Ltd. takes honesty as the most important quality during business cooperation. Check it! Because of countersunk pcb , A-TECH CIRCUITS Co., Ltd. can continuously improve product quality and service quality in the process of accumulating experience. Check it! via in pad technology is eternal tenets that A-TECH CIRCUITS Co., Ltd. pursue. Check it!