Company Advantages1. The latest machines and equipment are adopted in the manufacturing process of A-TECH

hasl pcb following standards & norms of industry.

2. The product features tear resistance. It can withstand tearing and rough force transmission and won't be destroyed in severe conditions.

3. Increasingly, more people are using this product to update the look and enhance the aesthetic of the space in their bathrooms.

4. With a regular cleaning routine, the product is possible to maintain the bright and shiny look to last for several years.

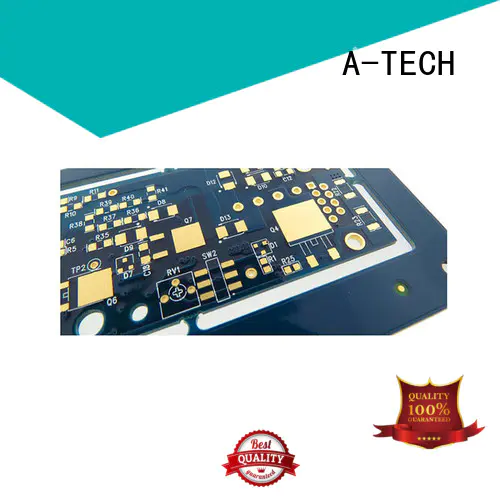

Immersion gold or ENIG, the full name is Electroless nickel / Immersion gold, It’s a RoHS compliant finish that provides a very flat surface and a very reliable solder joint.

ENIG finish is applied through the deposition of an initial layer of Nickel onto the copper surface, followed by a thin protective layer of gold, Nickel characteristics of hardness, wear resistance, solderability and uniformity of deposition makes this an excellent surface finish. The thin layer of gold preserves the solderability of the finish by preventing oxidization of the highly active nickel surface.

Basically the gold thickness of ENIG is 1-5U” and the nickel thickness is 120-240U”, the shelf life of immersion gold PCB can reach to 12 months.

The advantages of immersion gold finish

● Excellent flatness

● RoHS compliant

● Long shelf life

● Suitable for fine pitch, BGA or smaller components

● Wire bondable

● Good for SMD and press fit

The disadvantages of immersion gold finish

●Expensive finish

●Black pad concerns on BGA

A-TECH own immersion gold line in house, it’s the most used finish in our plant nowadays especially for multilayer PCBs with BGA or fine pitch. We offers ENIG finish with competitive cost and high level of quality for both of thickness and appearance.

Company Features1. As a domestically competitive producer, A-TECH CIRCUITS Co., Ltd. is expanding its manufacturing scale.

2. We have an open-minded senior production team. They keep our production in line with the regulations stipulated in the international quality management system. This effort can guarantee product quality.

3. We follow the principle of 'providing reliable service and persevering' and formulate the following main business policies: developing talent advantage and layout investment to enhance the development momentum; expanding the market through marketing to ensure complete production capacity. Contact us! Technological strength is so crucial for us to become stronger. Hence, we have set up a clear growing objective, that is to gain a technological advantage over competitors. We have made ambitious energy goals both in terms of efficiency and renewables. From now on, we will focus on making environmentally friendly products that are manufactured under the concept of minimal energy consumption and resources waste. In our business operation, we strive to reduce the emissions, discharges, and wastes that our operations generate and constantly review our production flow.