Company Advantages1. The quality test for A-TECH press fit pins pcb must be conducted. It has to go through a check for start-up and pause performance before delivery. With a compact design, it is space-saving

2. Technical support and press fit pins pcb will be provided by A-TECH CIRCUITS Co., Ltd. for our

countersink pcb . Being laminated by advanced vacuum lamination equipment, it has a uniform dielectric thickness after lamination

3. Through the devotion to the performance of press fit pins pcb, A-TECH CIRCUITS Co., Ltd. has received more and more orders. It is characterized by high thermal conductivity and good heat dissipation

4. Such conclusion can be reached that countersink pcb has several advantages as press fit pins pcb. It is vacuum-sealed, which can greatly reduce the bulk of the overall cargo

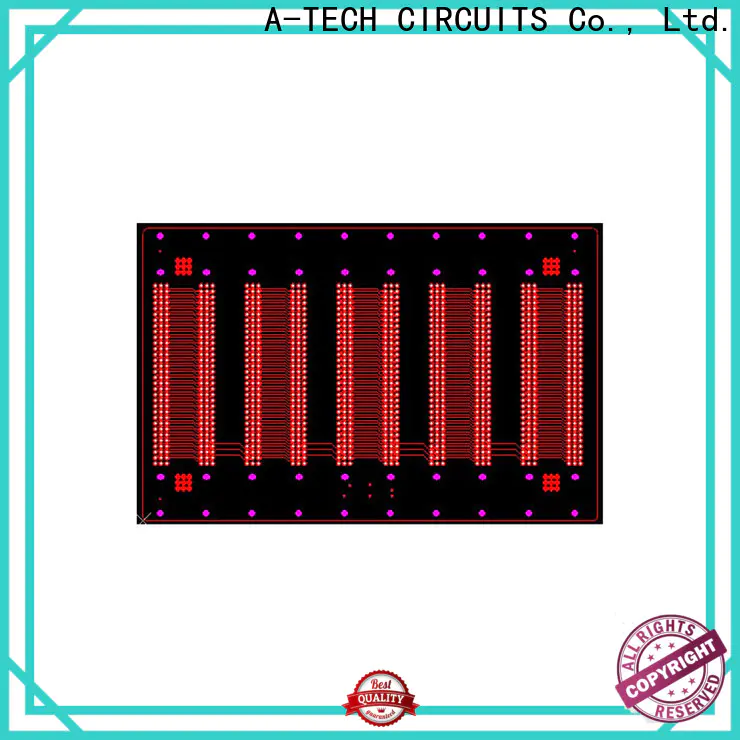

5. Modified by several times, countersink pcb can be applied into many different places. Thanks to the up-to-date vacuum DES line, it is manufactured with fine traces and high density

Press fit hole PCB, or called press fit pins PCB, they’re component holes with copper plated through and with tighter tolerance than standard PTH, the tolerance of standard PTH is +/-0.075mm(3mil), but the tolerance of press fit hole is normally +/-0.05mm(2mil).

Press fit holes are used as holes to fit the leads of connectors that will not be soldered but pressed into the holes. In order to accommodate lead and hole to tightly fit together, the tolerance on both are well defined, the typical tolerances for the press fit holes depends on the type of connector that is used and it’s the connector manufacturer who specifies this.

Press fit technology reduces PCB assembly time and effort considerably, and press fit pin eliminates the need for soldering, this cuts process time and cost, and boosts production output capacity. With no need to solder modules, engineers enjoy great flexibility in design. The module can easily be mounted on top or bottom of the PCB at no extra cost and effort.

A-TECH drill press fit holes with new drill bits and control specially in manufacturing process to ensure finished hole size within tolerance as specified.

Company Features1. A-TECH has always focused on producing first-class countersink pcb . A-TECH CIRCUITS Co., Ltd. stands out in R&D and technologies.

2. In order to accomplish technological innovation, A-TECH CIRCUITS Co., Ltd. has introduced professional technicians and innovative equipment.

3. We have a project management team. They will ensure that all our products will be delivered to our customers at the right time and right manner. We are committed to building a fair and just business environment. We will never conduct business that is illegal or harms the interest of the stakeholders.