Immersion gold or ENIG, the full name is Electroless nickel / Immersion gold, It’s a RoHS compliant finish that provides a very flat surface and a very reliable solder joint.

ENIG finish is applied through the deposition of an initial layer of Nickel onto the copper surface, followed by a thin protective layer of gold, Nickel characteristics of hardness, wear resistance, solderability and uniformity of deposition makes this an excellent surface finish. The thin layer of gold preserves the solderability of the finish by preventing oxidization of the highly active nickel surface.

Basically the gold thickness of ENIG is 1-5U” and the nickel thickness is 120-240U”, the shelf life of immersion gold PCB can reach to 12 months.

The advantages of immersion gold finish

● Excellent flatness

● RoHS compliant

● Long shelf life

● Suitable for fine pitch, BGA or smaller components

● Wire bondable

● Good for SMD and press fit

The disadvantages of immersion gold finish

●Expensive finish

●Black pad concerns on BGA

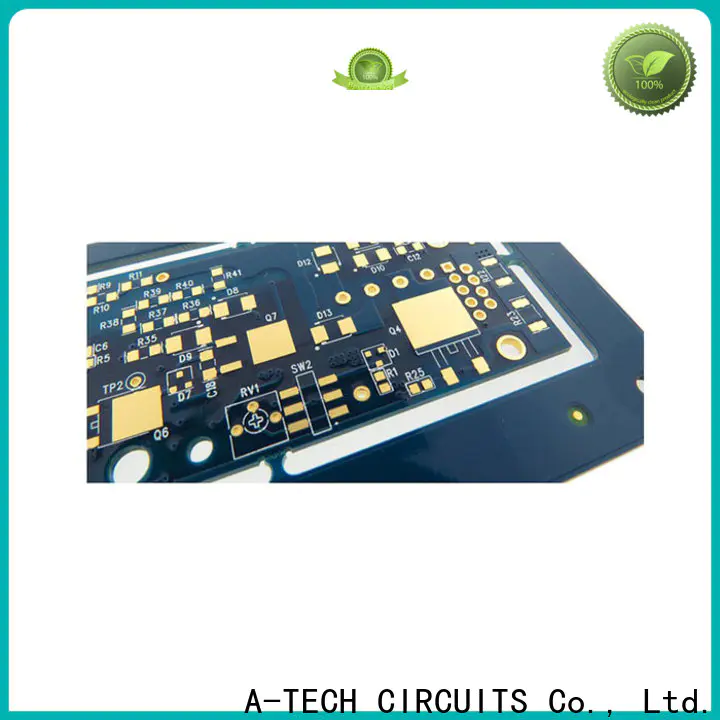

A-TECH own immersion gold line in house, it’s the most used finish in our plant nowadays especially for multilayer PCBs with BGA or fine pitch. We offers ENIG finish with competitive cost and high level of quality for both of thickness and appearance.

Copyright © 2025 A-TECH CIRCUITS Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.